Recommended video:

Cangzhou Zhongtuo roll forming machinery company is a professional trade enterprise. It integrates the production and sales of complete sets of metal plate cold rolling (roll forming and cold bending) forming equipment. Its comprehensive strength ranks high in the industry nationwide!

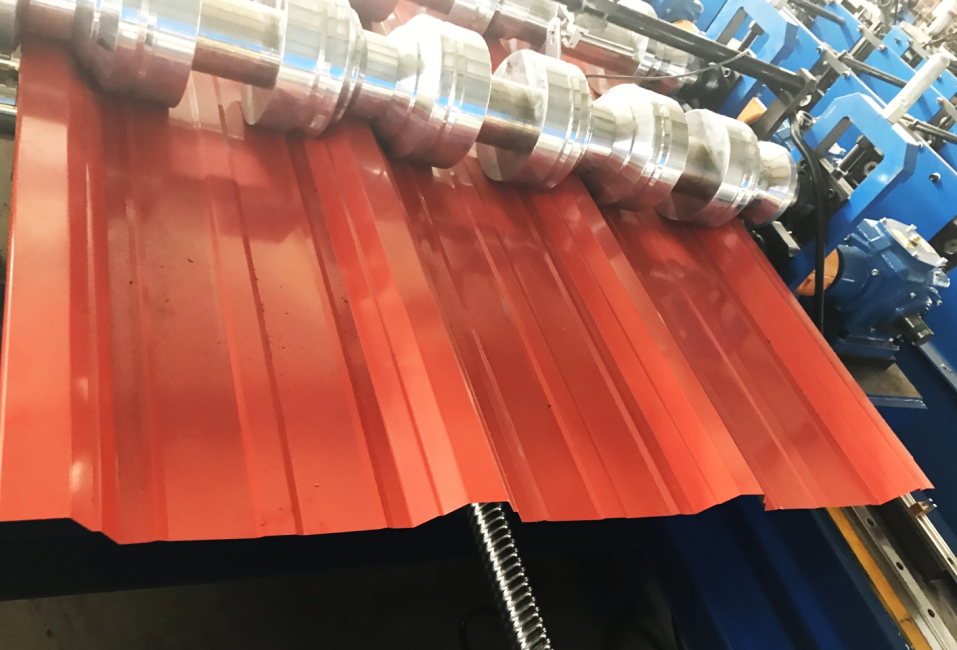

Now let’s have a look at their high speed trapezoidal roof panel roll forming machine for Ecuadorian customer.

The features of this roof panel roll forming machine:

- Efficient capacity: producing speed can reach 45 m per minute

- Transmission: by gearboxto ensure the production more stable and accuracy

- Forming system canensure perfect forming and intact surface of the roof panel

- Automatic production line is controlled by the control station

The technical specifications of Zhongtuo high speed trapezoidal roof panel roll forming machine:

1.10 tons hydraulic Uncoiler:

- Capacity:10 tons

- Coil width: max 1250mm

- Working type:active type;automatic speed adjustment;4 support arms design: support the coil and prevent crease when uncoiling

- Make sure a high-speed feeding of the material

- The car can move levelly and vertically, which is convenient for putting the steel coils into the uncoiler.

2.Roll forming system:

| Basic frame structure | 45# steel makes the basic frame and 40mm thickness arch structure;connected with the body by bolts and nuts |

| Roller Station | 19 stations |

| Roller material | 45#,finishing after quenching heat treatment |

| Transmission | by gearbox |

| Speed | 0-45 m/min |

| Four peaks | |

| Motor | Bojiang brand with 11kw |

3.Hydraulic servo cutting system

- Automatic hydraulic cutting controlled by PLC

- no-stop cutting design: moving by the servo motor

- Material of cutting blade:GCr12Mov

- Double line of nut to fix the cutting blades

- Steady and safe working condition and low sounds