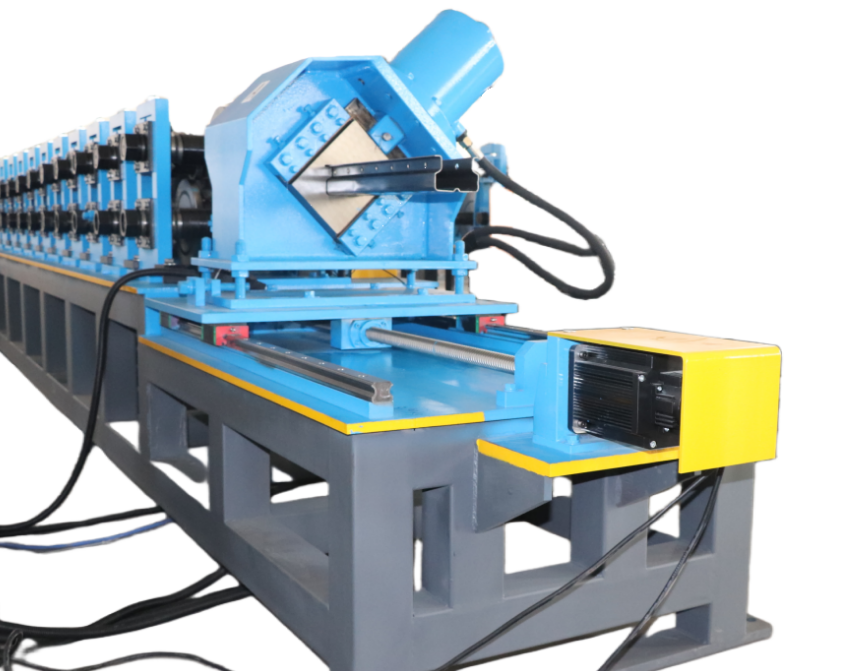

Upright Pillar Rolling Forming Machine

The Upright Pillar Rolling Forming Machine is a specialized equipment used for producingUpright Pillars . It integrates multiple process flows, including feeding, leveling, punching, forming, laser welding, and cutting, achieving full automation and reducing customer’s secondary processing troubles. Widely used in the production of storage shelves, it can produce products that meet various specifications and requirements to meet different storage needs.

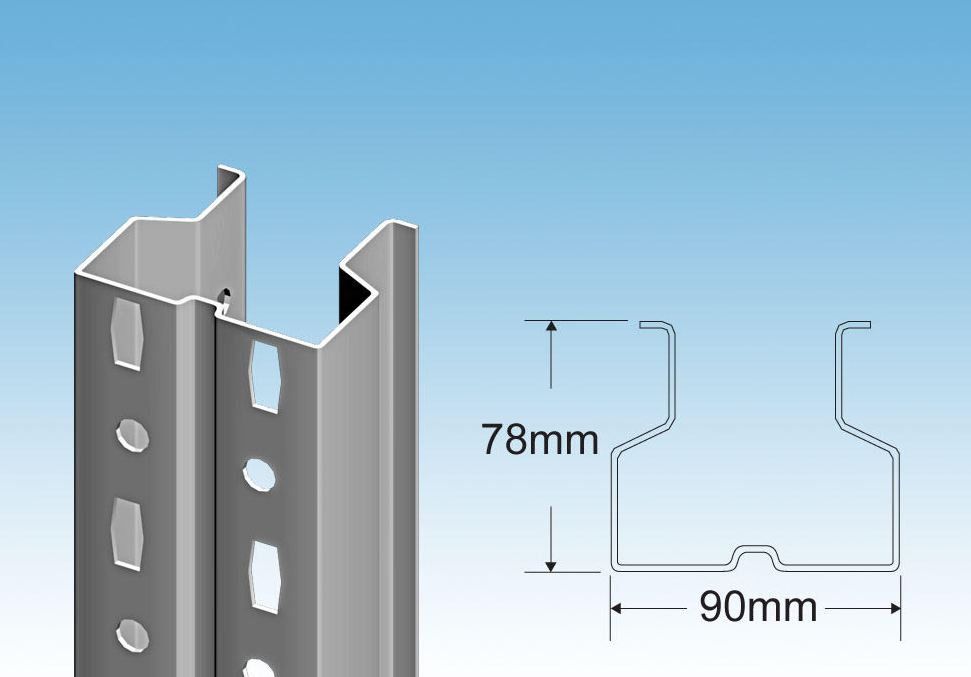

Profile Drawing:

Typical Applications:

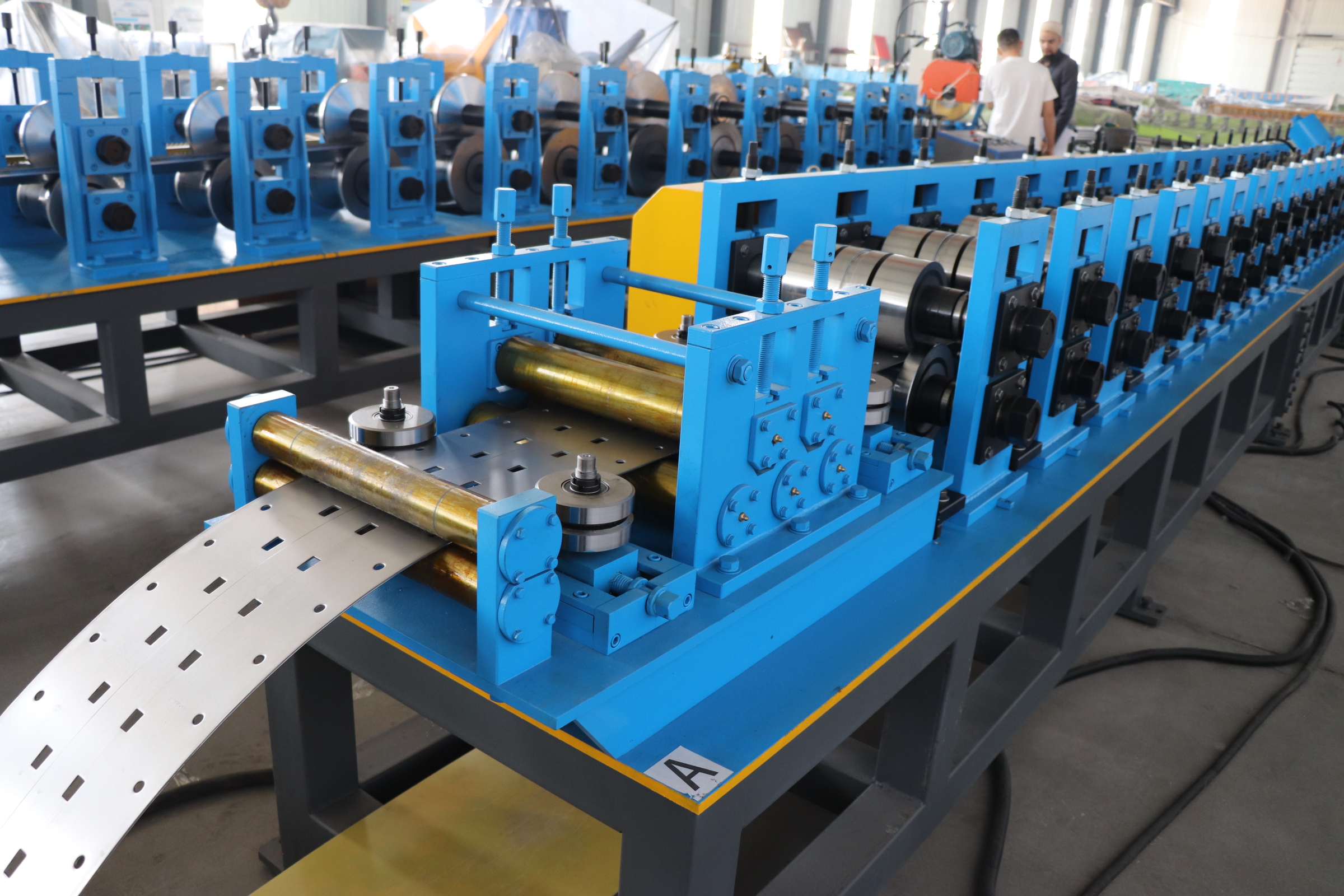

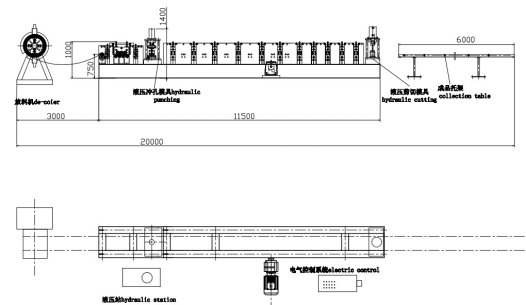

Upright rack Roll Forming Machine working flow:

Hydraulic De-coiling—Material guiding—Levelin—Hydraulic punching—Roll forming—Length sizing—Cutting the panel—Panels to the collecting platform—Finish

The technical specifications:

1.Formed Material | PPGI,GI,AI | Thickness:1.5-2.7mm | ||

2.Decoiler | Hydraulic automatic decoiler | will give you as free | ||

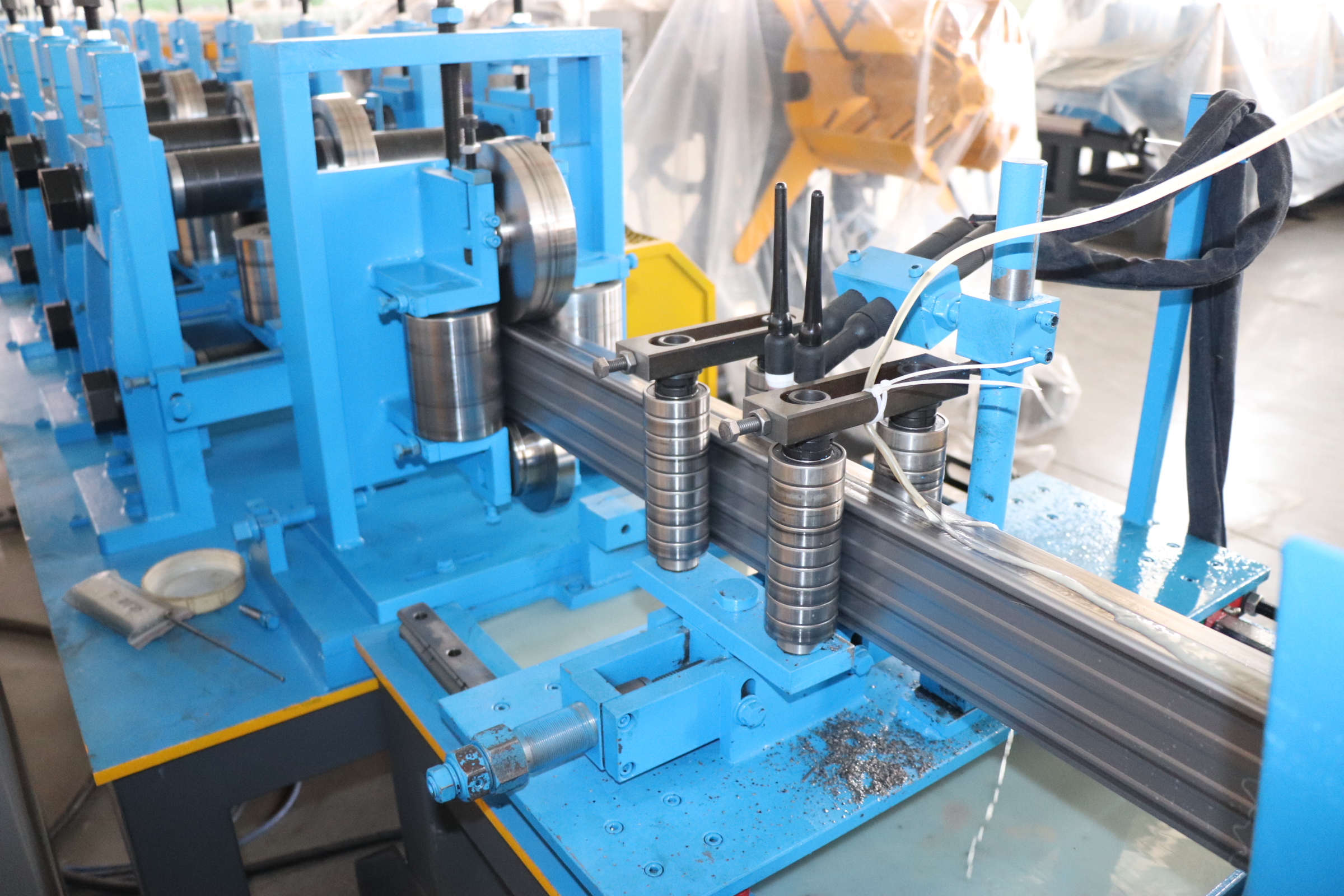

3.Main body | Roller station | As your requirement | ||

Diameter of shaft | As your requirement | |||

Material of rollers | 45# steel, hard chrome plated on the surface | |||

Machine body frame | Metal steel welded | |||

Drive | gearbox transmission | |||

Dimension(L*W*H) | customize | |||

Weight | About 75T | |||

4.Cutter | Automatic | cr12mov material, no scratches, no deformation | ||

5.Power | Motor Power | 7.5KW | ||

Hydraulic system power | 5.5KW | |||

6.Voltage | 380V 50Hz 3Phase | As your requirement | ||

7.Control system | Electric Box | Customized(famous brand) | ||

Language | English(Support multiple languages) | |||

PLC | Automatic production of the whole machine. Can set batch, length, quantity, etc. | |||

18.Forming Speed | customized | The speed depends on the shape of the tile and the thickness of the material. | ||