In the world of metal fabrication, roll forming machines have emerged as game-changers, offering unmatched efficiency, precision, and versatility. These advanced machines have revolutionized the process of shaping metal sheets or coils into desired profiles with consistent quality. In this article, we will explore the remarkable capabilities of roll forming machines and how they have transformed the field of metal fabrication.

Understanding Roll Forming Machines:

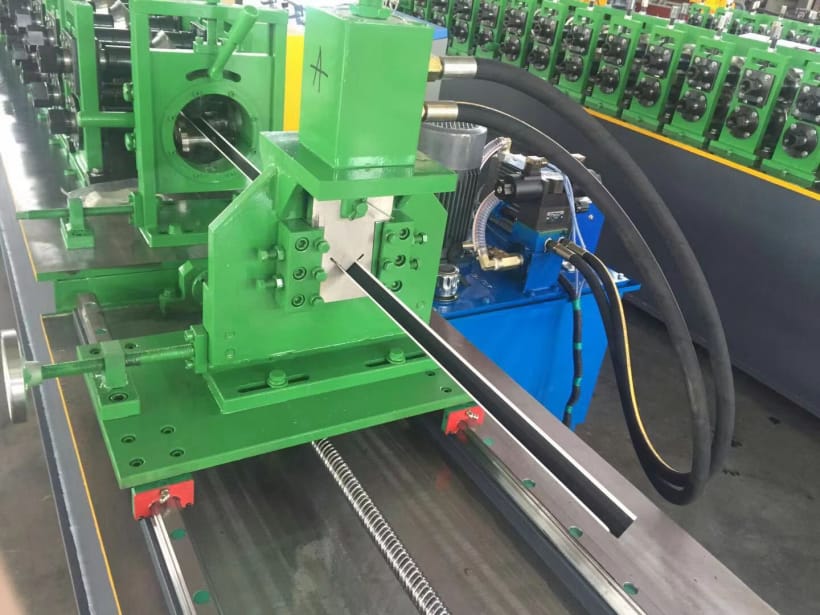

Roll forming machines are mechanical systems that utilize a series of rollers to gradually shape and form metal sheets or coils. The process involves feeding the material through a set of precisely designed rollers, each performing a specific bending or forming operation. As the metal passes through the rollers, it undergoes continuous shaping and gradually takes the desired profile. Roll forming machines can handle various metals, including steel, aluminum, copper, and stainless steel, allowing for a wide range of applications.

Efficiency and Productivity:

One of the key advantages of roll forming machines is their exceptional efficiency and productivity. These machines can operate at high speeds, ensuring rapid production of metal profiles with consistent dimensions. The continuous nature of the process minimizes material waste and reduces downtime associated with tool changes or setup adjustments. With automated feeding and cutting systems, roll forming machines enable seamless integration into production lines, streamlining the manufacturing process and increasing overall productivity.

Versatility and Customization:

Roll forming machines offer remarkable versatility, making them suitable for various industries and applications. The modular design of these machines allows for easy customization, facilitating the production of a wide range of profiles, including channels, angles, tubes, panels, and more. By adjusting the roller sets and other parameters, manufacturers can tailor the machine to meet specific design requirements, ensuring precise dimensions and high-quality output. This flexibility makes roll forming machines ideal for diverse industries such as automotive, construction, aerospace, and furniture.

Consistent Quality and Precision:

Consistency in profile dimensions and quality is a hallmark of roll forming machines. The carefully engineered rollers and computer-controlled systems ensure that each metal profile produced maintains the desired shape, dimensions, and surface finish. This consistency is crucial for industries that require standardized components, ensuring proper fit, functionality, and aesthetic appeal. Additionally, the use of advanced sensors and monitoring systems allows for real-time quality control, minimizing the risk of defects and ensuring high-quality output.

Cost-Effectiveness and Material Efficiency:

Roll forming machines contribute to cost-effectiveness in metal fabrication. The efficient utilization of materials and minimal waste generation result in cost savings over traditional fabrication methods. Roll forming machines can handle thin-gauge materials, allowing manufacturers to use lighter and less expensive metals without compromising strength or durability. Moreover, the high-speed production capability of these machines translates into shorter lead times, reducing manufacturing costs and improving overall project timelines.

Roll forming machines have revolutionized the field of metal fabrication, offering unparalleled efficiency, precision, and versatility. Their ability to shape metal sheets or coils into precise profiles with consistent quality has transformed industries across the globe. From automotive components to construction materials, roll forming machines have become indispensable in the manufacturing process. Embracing the power of these advanced machines allows manufacturers to enhance productivity, achieve cost savings, ensure consistent quality, and meet the ever-evolving demands of the market. With their limitless possibilities, roll forming machines continue to shape the future of metal fabrication.