ZTRFM Forming takes pride in delivering top-notch roll forming solutions, and the Type A Roof Deck Roll Forming Machine is a testament to their commitment to excellence. With its superior performance, precision engineering, and advanced control systems, this machine is an indispensable tool for manufacturers aiming to optimize production and deliver reliable and durable Type A roof decks for a wide range of applications in commercial, industrial, and residential buildings.The Type A Roof Deck Roll Forming Machine, showcased on ZTRFM Forming’s website, is an advanced and efficient industrial equipment designed for producing Type A roof decks. This cutting-edge machine utilizes state-of-the-art roll forming technology to transform metal sheets into precise and high-quality Type A roof deck profiles.With its automated operations, the machine ensures consistent and accurate results, optimizing production efficiency and reducing labor costs. It offers flexibility in creating various sizes and designs of roof decks, catering to diverse construction needs and project requirements.

What is Type A Roof Deck?

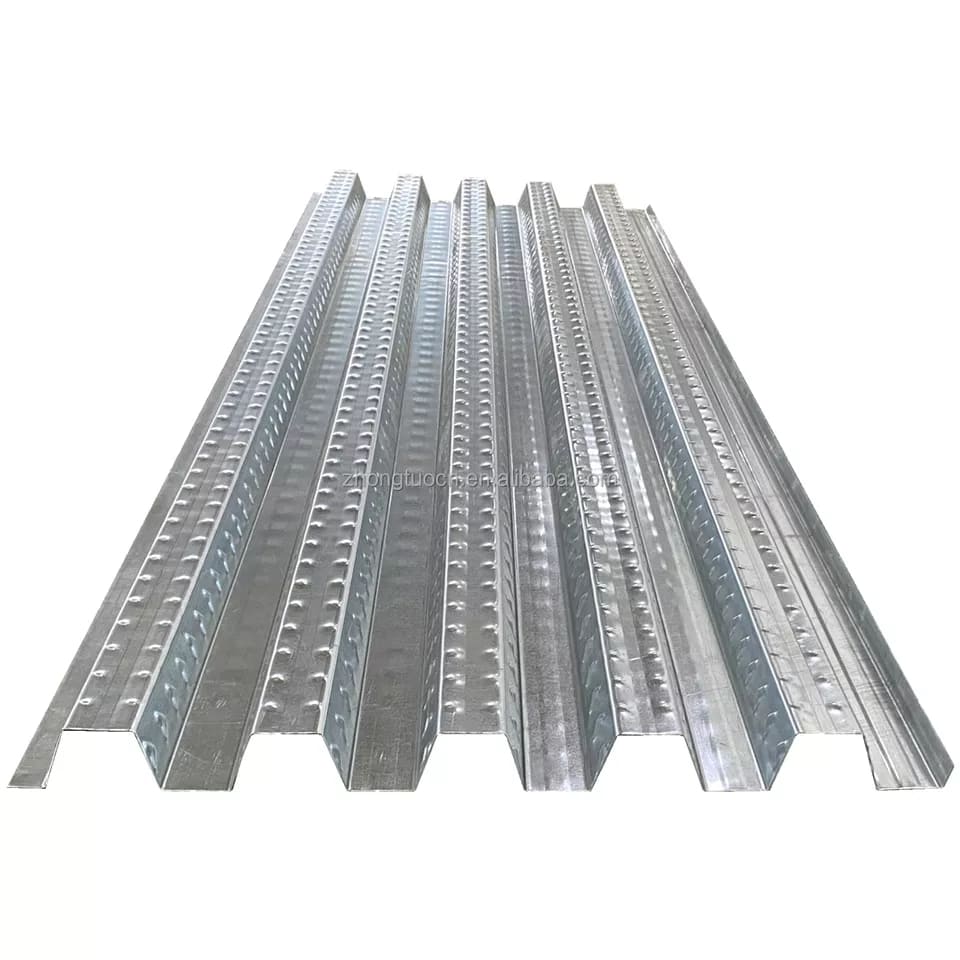

Type A roof deck is the “original” term for this deck profile, though recently the Steel Deck Institute has promoted the more descriptive name, “Narrow Rib Roof Deck”, or “Type NR”.

Unlike other types of metal roof decking, Type A roof deck is rarely used for new construction projects, but is often needed for repair and re-roof projects. This is due to the fact that Type A roof decking is the least efficient 1.5” deep steel roof deck section. Compared to Type B and Type F roof decks, Type A metal roof decks have the lowest strength-to-weight ratio. As with all steel products, the lighter the section, the more economical it will be. And since Type A roof deck cannot carry as much load at longer spans as B deck and F deck, the steel supports below the metal deck must be spaced closer together. In turn, a smaller support spacing results in more supports and higher costs for the building owner.

The drawing profile is as following:

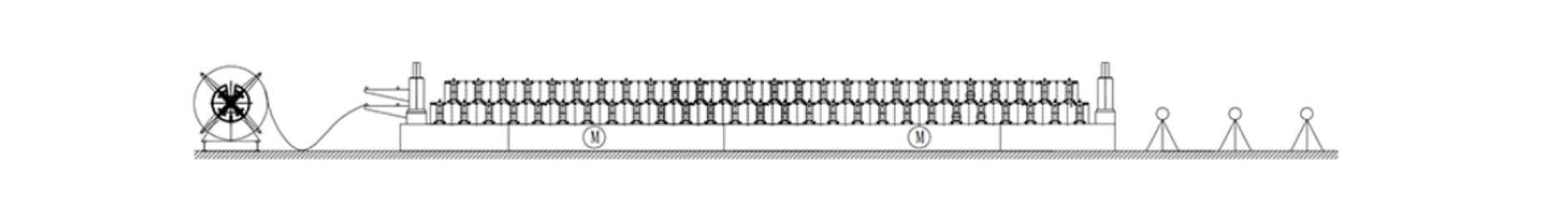

Based on the drawing profile ,we design the Type A steel roof decking roll machine as following for your reference:

Type A steel roof decking roll machine Work Flow .

5T Hydraulic Decoiler-→Manual Pre-Cutter Device- + Feeding Guide Device-→Roll Forming System- >Hydraulic Post Cutter Device-→AUTO Exit Rack

Advantages of Metal Floor Deck Machine are as follows:

1.Floor decking sheet produced by this machine has the features of low cost , light weight buy high strength ,shorten building period and re-cycle use .

2.Save material with no waste

- Easy operation , low maintenance cost

- It is easy for installation.

When using Type A roof deck to cover skylights, note that 20 gauge deck or heavier will probably be required since 22 gauge will only span 3’-9” (see maximum unshored spans for one (1) span). As shown in the Maximum Construction Span table on this page, the maximum span for one span is 10 inches shorter than the maximum allowed when two or more spans are covered by each deck sheet.