Trapezoidal metal roofing sheet machine can produce roof sheets of different shapes,usually different countries have its own popular design ,we can customize the machine as customers’ demand,Trapezoidal metal roofing sheet machine is most popular in Egyptian market.

The design of trapezoidal metal roofing sheets contributes to the stability and durability of buildings. In ancient Egypt, these tiles were able to maintain their shape and function in hot and dry climates, preventing cracking or damage caused by temperature changes.

In the evolution of form from entity to space, ancient Egyptian architecture exhibits a sense of space and three dimensionality. The use of t trapezoidal metal roofing sheets helps to create a sense of space in buildings.

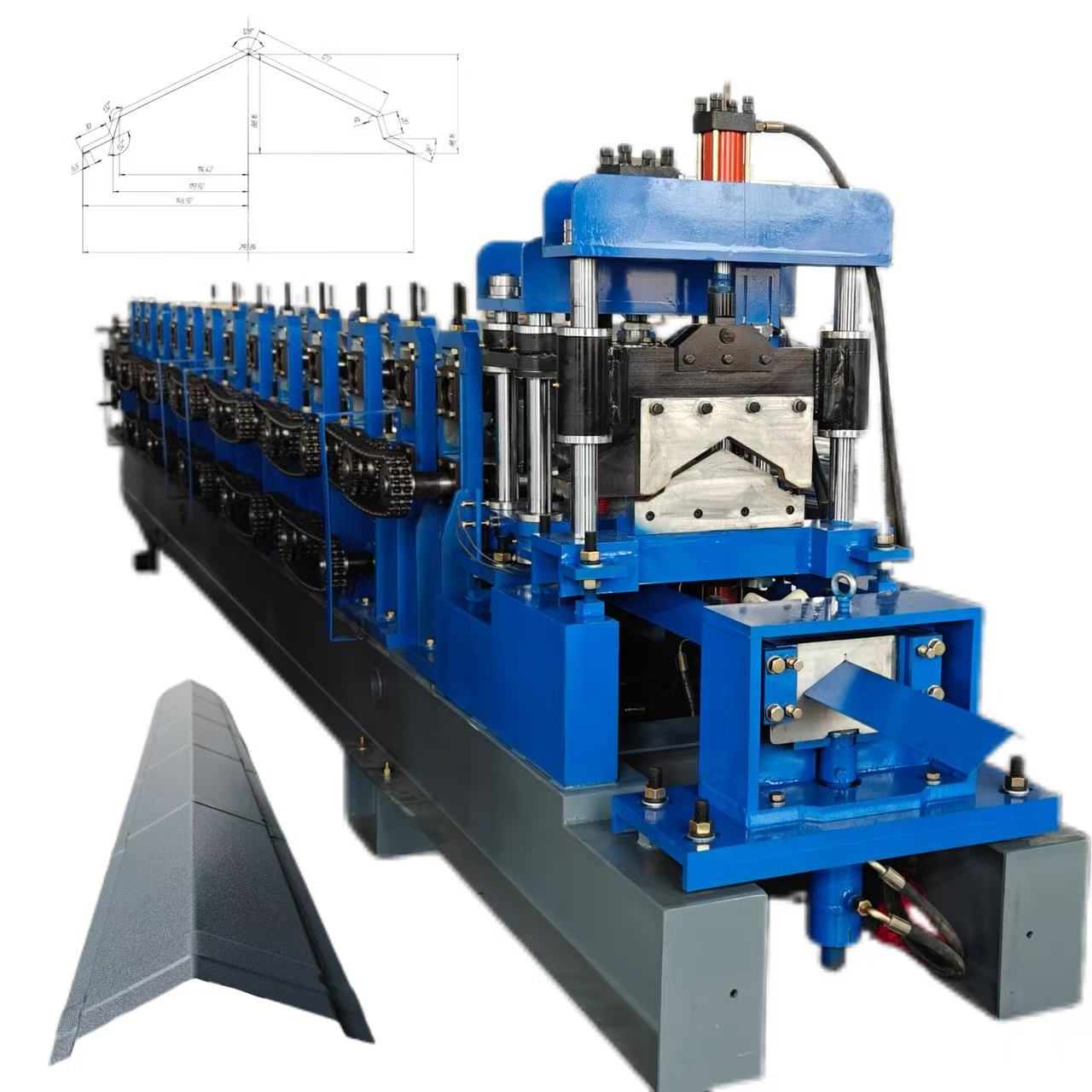

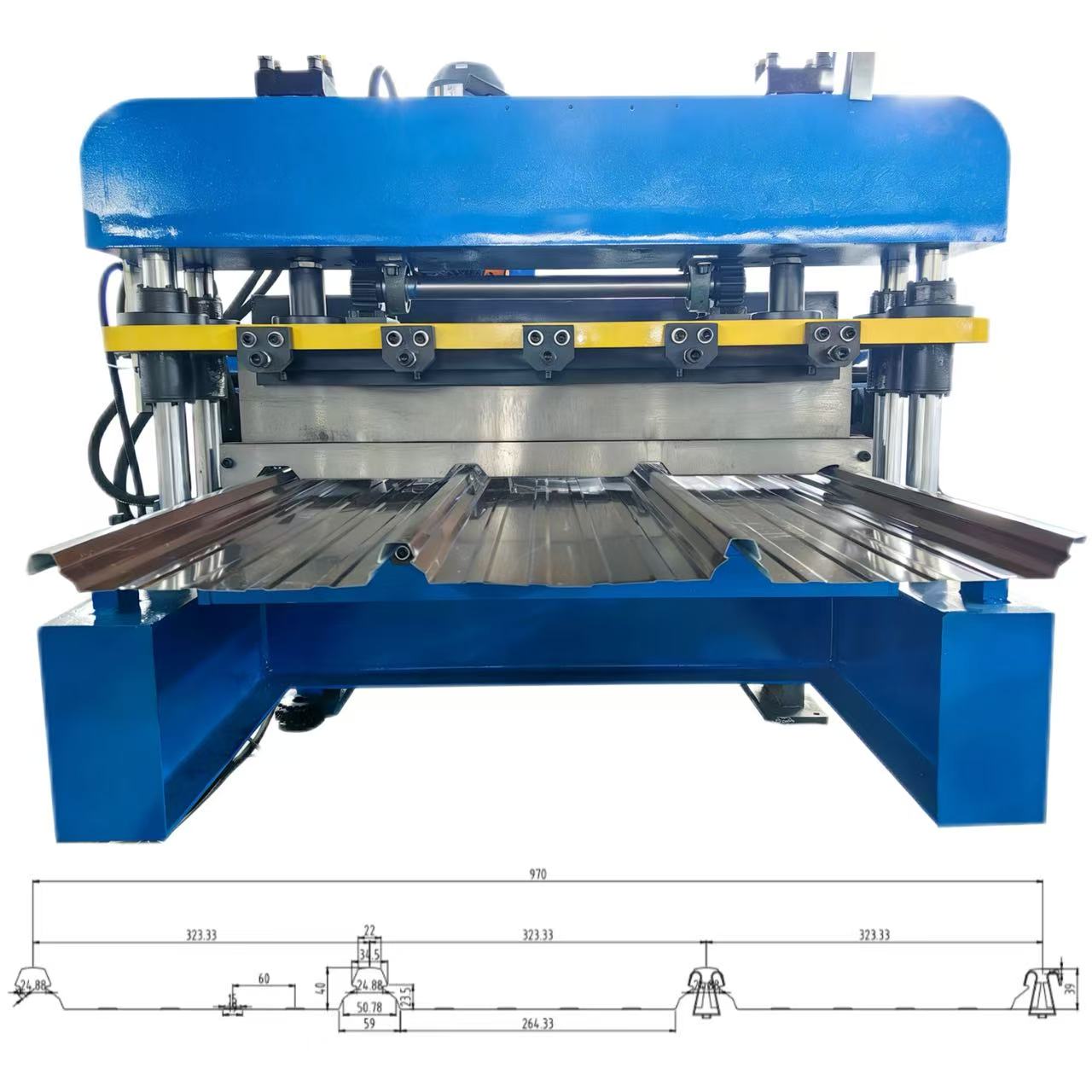

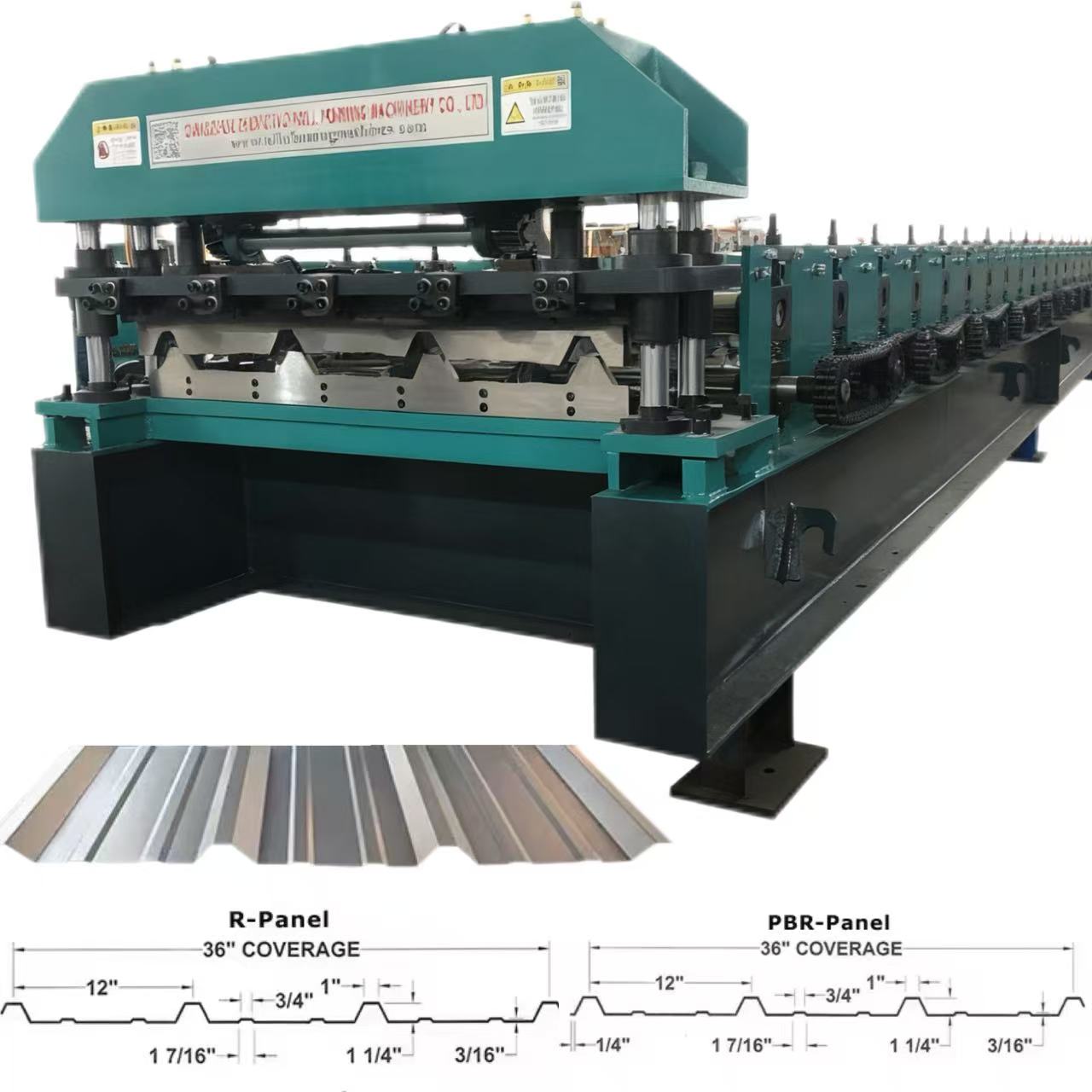

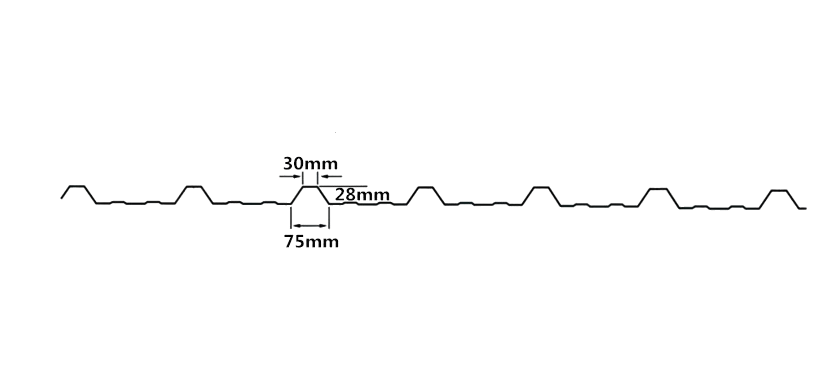

Sectional view of the Trapezoidal metal roofing sheet machine:

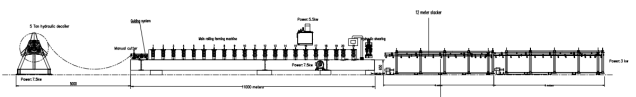

Working Flow as Below:

Uncoiling → Feeding material into machine →Roll forming → Auto cutting →Products receiving table

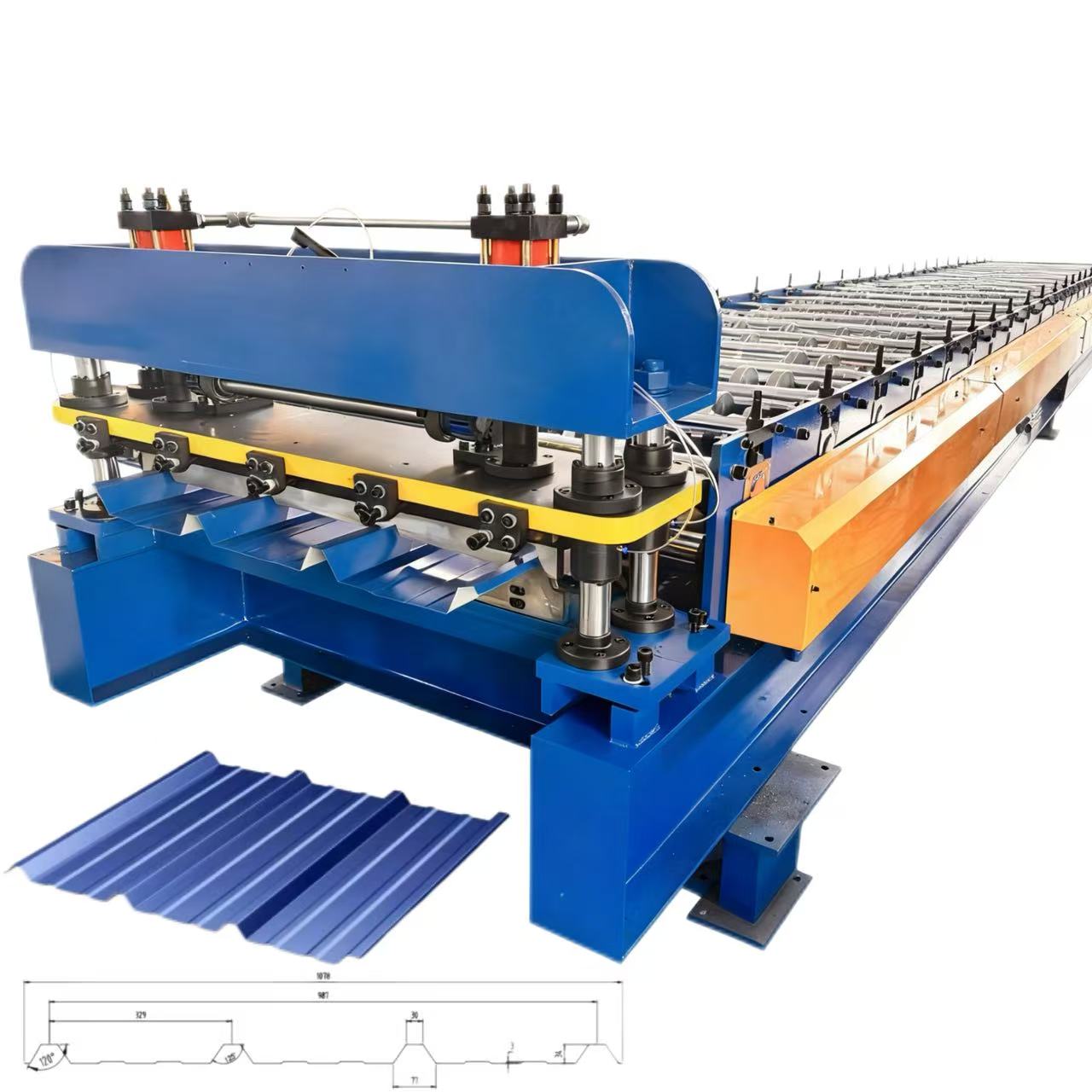

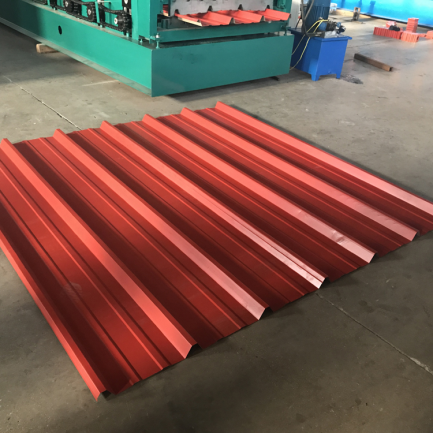

Finished product photos of the Trapezoidal metal roofing sheet machine:

The main functions of the Trapezoidal metal roofing sheet machine:

1. Waterproof and Drainage:

One of the main functions of Trapezoidal metal roofing sheets is to prevent rainwater from leaking into the house and help with roof drainage, which is particularly important for a country like Egypt with a hot climate and the possibility of sudden rainfall.

2.Insulation and heat preservation:

Trapezoidal metal roofing sheets can effectively insulate and prevent direct transfer of solar radiation heat during the day to the interior. When roofing sheets are overlapped and laid on a pointed sloping roof, an air gap for insulation can be created, thereby improving indoor comfort.

3.Aesthetics and Decoration:

Wadang, also known as the head end of a tile, was used for the roof of ancient buildings. It not only had practical functions, but also added beauty to the building. In Egypt, the design and arrangement of these roofing sheets also reflect the aesthetics and culture of ancient Egyptians.

4.Protecting the building structure:

Trapezoidal roof tiles can protect the wooden roof truss, prevent rainwater erosion, and extend the service life of the building.

The technical specifications of theTrapezoidal metal roofing sheet machine:

| Item | Name | Specifications |

| 1 | Raw material | PPGI steel coils |

| 2 | Material thickness | 0.3mm-0.8mm |

| 3 | Machine frame | welded separately and the outside wall is connected by screw after being rotoblasted on the surface |

| 4 | Material of rollers | High grade 45# forged steel,Chromed treatment |

| 5 | Roller stand | Memorial archway structure |

| 6 | Forming stations | 18 rows |

| 7 | Diameter of shafts | 90mm |

| 8 | Material of shafts | High grade 45#,with heat treatment |

| 9 | Forming speed | 15 m/min |

| 10 | voltage | 415V/50HZ/3Phase(can be custom by client’s requirement) |

| 11 | Transmission way | By chains |

| 12 | Main motor | 5.5 KW |

| 13 | Cutting blade material | Cr12mov with quenched treatment |

| 14 | Cutting type | Hydraulic cutting |

| 15 | Driving method | By pillar type Cylinder |

The components of the machine:

| No. | Name | Quantity |

| 1 | 5T hydualic decoiler. | 1 set |

| 2 | Main roll forming machine | 1 set |

| 3 | Hydraulic cutting system | 1 set |

| 4 | PLC control station | 1 set |

| 5 | Product receive table | 1 set |

Some details of the Trapezoidal metal roofing sheet machine: