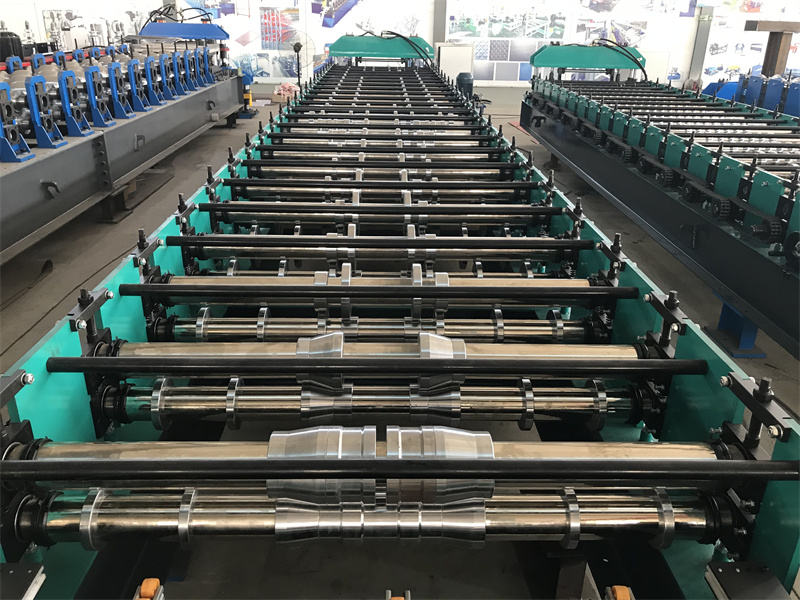

The TR4 IBR Roofing Sheet Roll Forming Machine is a cutting-edge and efficient solution for manufacturing TR4 IBR roofing sheets. This state-of-the-art machine is specifically designed to produce high-quality roofing sheets with a TR4 IBR profile, known for its excellent performance and durability. With precision engineering and automated controls, it ensures seamless and accurate roll forming, resulting in consistent and precise TR4 IBR roofing sheets. The machine is versatile and can handle various materials, such as steel, aluminum, or other alloys, making it ideal for a wide range of roofing applications. Experience superior roofing sheet production and elevate your construction projects with this reliable and high-performance TR4 IBR Roofing Sheet Roll Forming Machine.

TR4 roofing sheet making machine ibr roll forming machine popular in Peru market

Design Idea:

Stable Transmission: Double chain and gear drive,keynote rollers design.

Easy Operation:Only need to set orders on the PLC control station,very easy operation.

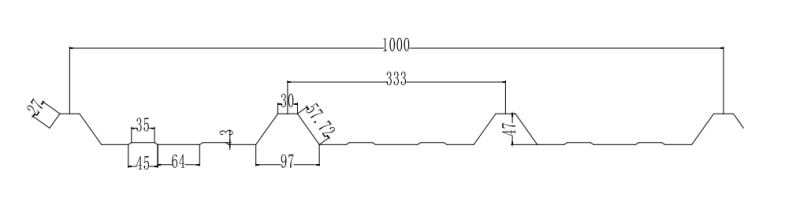

Profile drawing for reference:

Trapezoidal roofing sheet has many different shapes,usually different countries have its own popular design ,we can customize the machine as customers’ demand,R101 roofing sheet is most popular in Mexico market.

Processing Flow

TR4 Roofing Sheet Roll Forming Machine Hot Sale To Mexico | |

Raw Material | PPGI,PPGL |

Material Thickness:24/26 Gauge (0.4-0.6 Mm) | |

Machine Frame | 350mm H Beam Structure, With 18mm Welded Steel Middle Support Plate. |

Roller Material | 45# steel, chromed on the surface |

Forming Stations | Roller Stations :22 Rows |

Diameter Of Shafts | Φ80mm Solid |

Material Of Shafts | High Grade 45#,With Heat Treatment |

Forming Speed | 15 M/Min |

Voltage | 380v/50hz/3p (As Requested) |

Transmission Way | By 1 Inch Chain (Double Chains) |

Main Motor | 5.5 KW |

Cutting Blade Material | Gcr12 quenched treatment |

Cutting Type | hydraulic post cutting |

Driving Method | By pillar type Cylinder |

5T Manual Decolier For Free

Capacity:5 tons Coil inner diameter:450-550mm Feeding width: max 1220mm Structure: welded by the steel plates and profiled bar. The shrink and expand of core is manually, with manual brake,The coil moving forward or reverse is pulled by roll forming machine

Feeding Device

1.Hand wheels on both sides can be used to adjust the feeding width. 2.Four stainless rollers can make the material go into the machine smoothly and prevent the scratch on the material surface. 3.There are three rows of orange plastic rollers can make the steel coil go into the machine smoothly.

Roll Forming And Transmission Device

1.rollers thick chromed good hardness for long service time. 2. Each roller has number and with keynotes, it can fix on the shaft stablely 3.gear and double chain,stable

Hydraulic Cutting Device

We use four pillars cutting system structure, it can make sure the cutting stable

PLC control system

PLC brand:Delta(Taiwan) PLC, and transducer and touched screen

● Encoder brand:Omron

● Electrical components:Schneider

●Operating language:English and Chinese(or as requested) You can set the orders on this part,changing product length and quantity,it is really easy to operate,and there are aviation plugs to make it much easier to install the machine while it arrived.

Hydraulic station

● Hydraulic station motor:5.5KW

● Hydraulic oil:46# hydraulic oil

● Main components:Include a set of hydraulic tank, a set of hydraulic oil pump, two hydraulic pipes. And one of electromagnetism valve