The Steel Stud Framing System is a robust and versatile solution for constructing sturdy and reliable steel stud frames. This cutting-edge system is specifically designed to create high-quality steel stud frames with precision and efficiency. With its advanced components and precise engineering, it ensures seamless assembly, resulting in consistent and durable steel stud structures. The system is compatible with various steel stud sizes and lengths, making it ideal for a wide range of construction applications, such as commercial buildings, residential projects, and interior partitions. Experience superior performance and easy installation with this reliable and high-performance Steel Stud Framing System, the perfect choice for your framing needs.

Steel Stud Framing System roll forming machine / grouting keel rolling machine

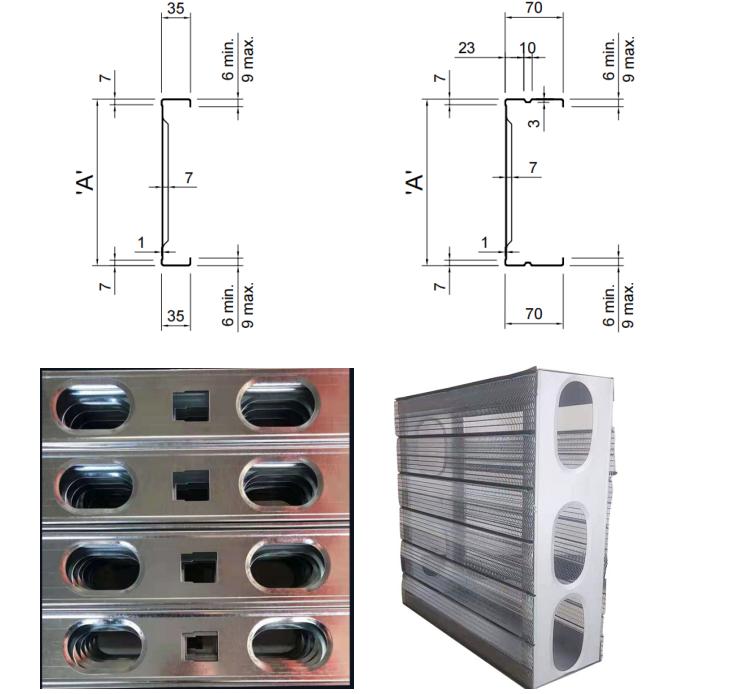

The grouting keel is made by rolling galvanized steel strips or thin steel plates through multiple processes using a special rolling mill. It has high strength and permeability.

It has the advantages of strong usability, good fire resistance, and easy installation, and can be used to assemble various types of gypsum boards, calcium plastic boards, sound-absorbing boards, etc. Supported by partition walls and keels, it is aesthetically pleasing. It is widely used in various civil construction projects and light textile industry sites, etc. So, it has a good effect on indoor styling, sound insulation, and other functions.

Material: galvanized steel plate/aluminum zinc plated steel

Thickness (mm): 0.6~1.5mm

Application scope: secondary structure household division, frame structure, frame shear structure filling partition, factory firewall, cold storage insulation wall

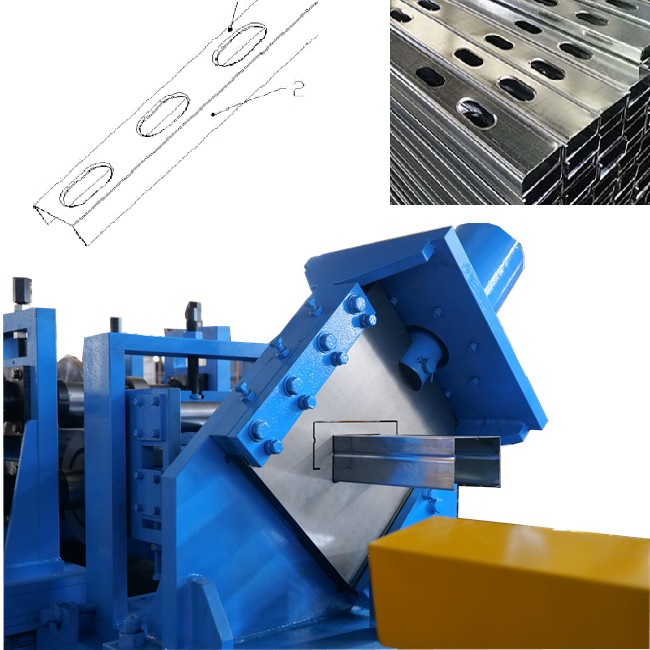

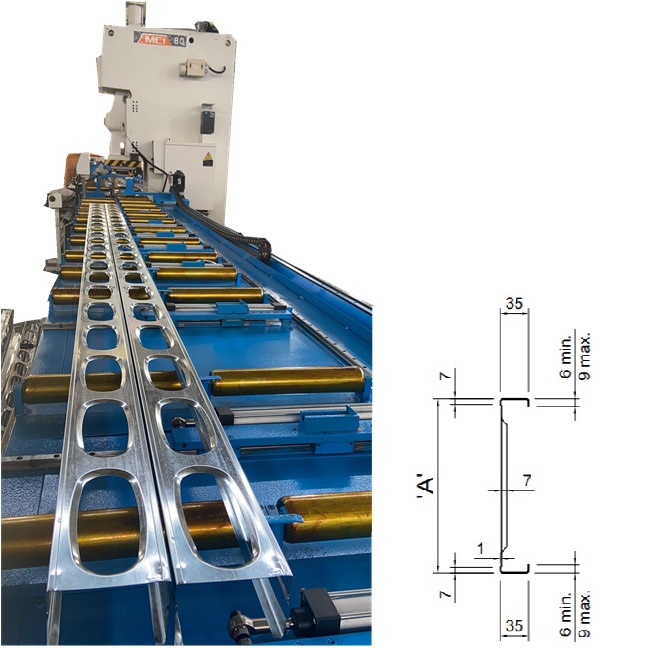

Here is the drawing profile for your reference:

Steel Stud Framing System rolling forming machine / grouting keel rolling machine

Working flow:

Production line process: uncoiling, forming, cutting, conveying, and robotic feeding, punching, and discharging (automatic operation throughout the line, no manual labor required).

It is composed by the following elements:

- 3 Ton vertical hydraulic uncoiler with brake,

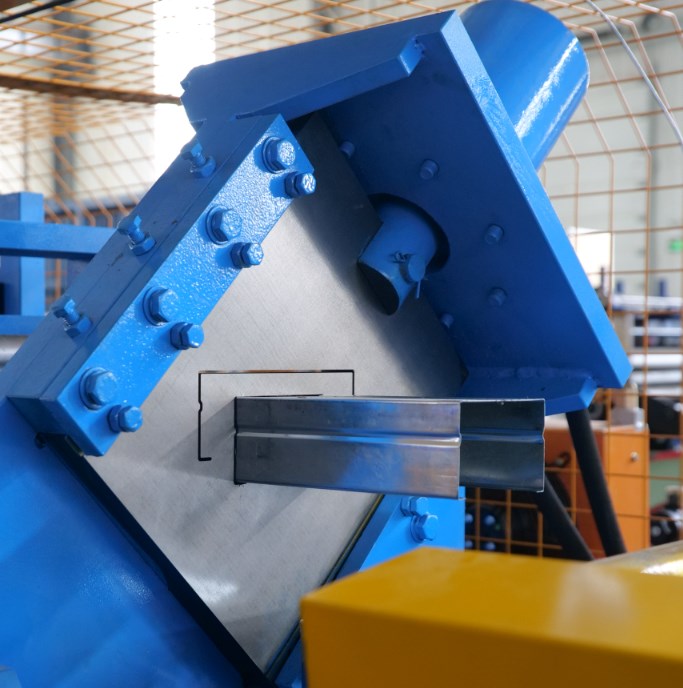

- Main rolling Forming part: memorial archway structure, chain drive, 17 rows forming, chrome 12 quenching and finishing turning for roller, shaft quenching and tempering treatment diameter 70mm, shutdown and cutting, main motor power: 11+11KW

- Convey table: 11KW large valve with air-cooled pump station, Zhongtuo portable control cabinet, PLC and screen Delta brand (PLC has 12 backup circuits), low-voltage electrical appliances Schneider brand counter Omron language requirements: Chinese/English

- Sometimes it is necessary to hit the high waist spot, sometimes it is not necessary

- Special requirements: Chain and sprocket 16B-1, 19 teeth

- Special requirements: Voltage 415V 50HZ 3ph

- Special requirements: The entire machine is equipped with a protective cover, and the main control cabinet has sensors connected to the PLC. The safety cover is opened and the main machine stops running

- 8.80 ton Yangli brand punch press with 6 sets of molds

- Automatic discharge rack 6 meters

Where to use:

Steel Stud Framing System rolling forming machine working videos for your reference: