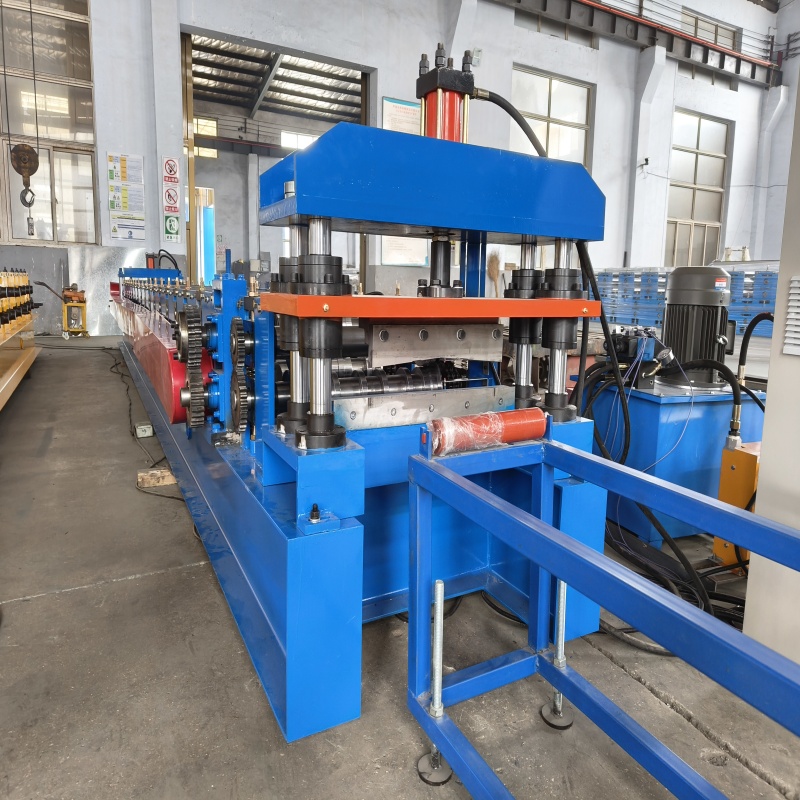

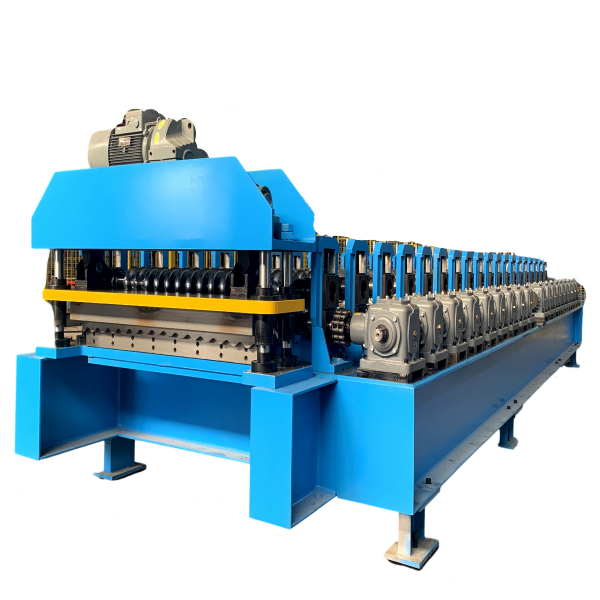

Standing Seam Roofing Sheet Machine is a mechanical equipment used for producing roof tiles with vertical seams. It has the characteristics of high efficiency, flexibility, and strong adaptability, and is widely used in the manufacturing of roof tiles for various buildings.

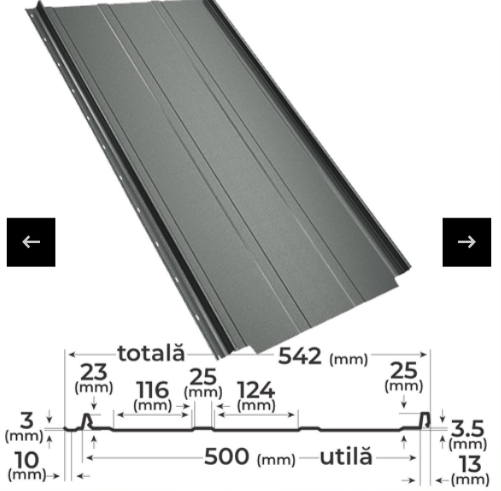

The pictures for the finished product:

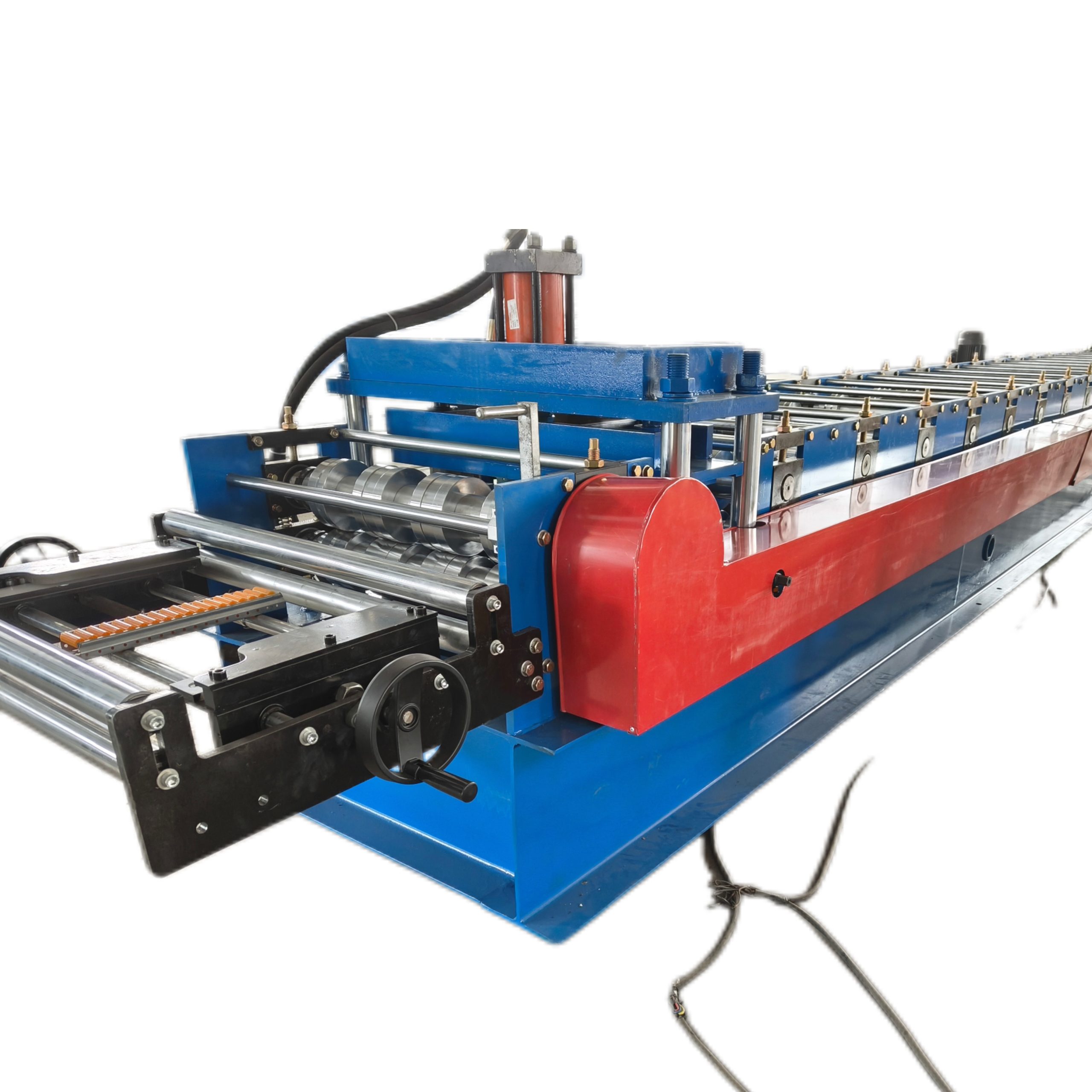

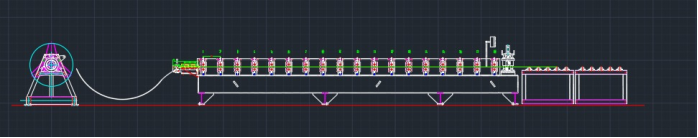

Production process:

Uncoiler-Feeding material into machine→Roll forming→hydraulic cutting→ Products receiving

Packing list of the Standing seam roofing sheet machine:

| Item | Description of Item | Unit | Quantity |

| 1 | 3T hydualic decoiler | set | 1 |

| 2 | Main roll forming machine | set | 1 |

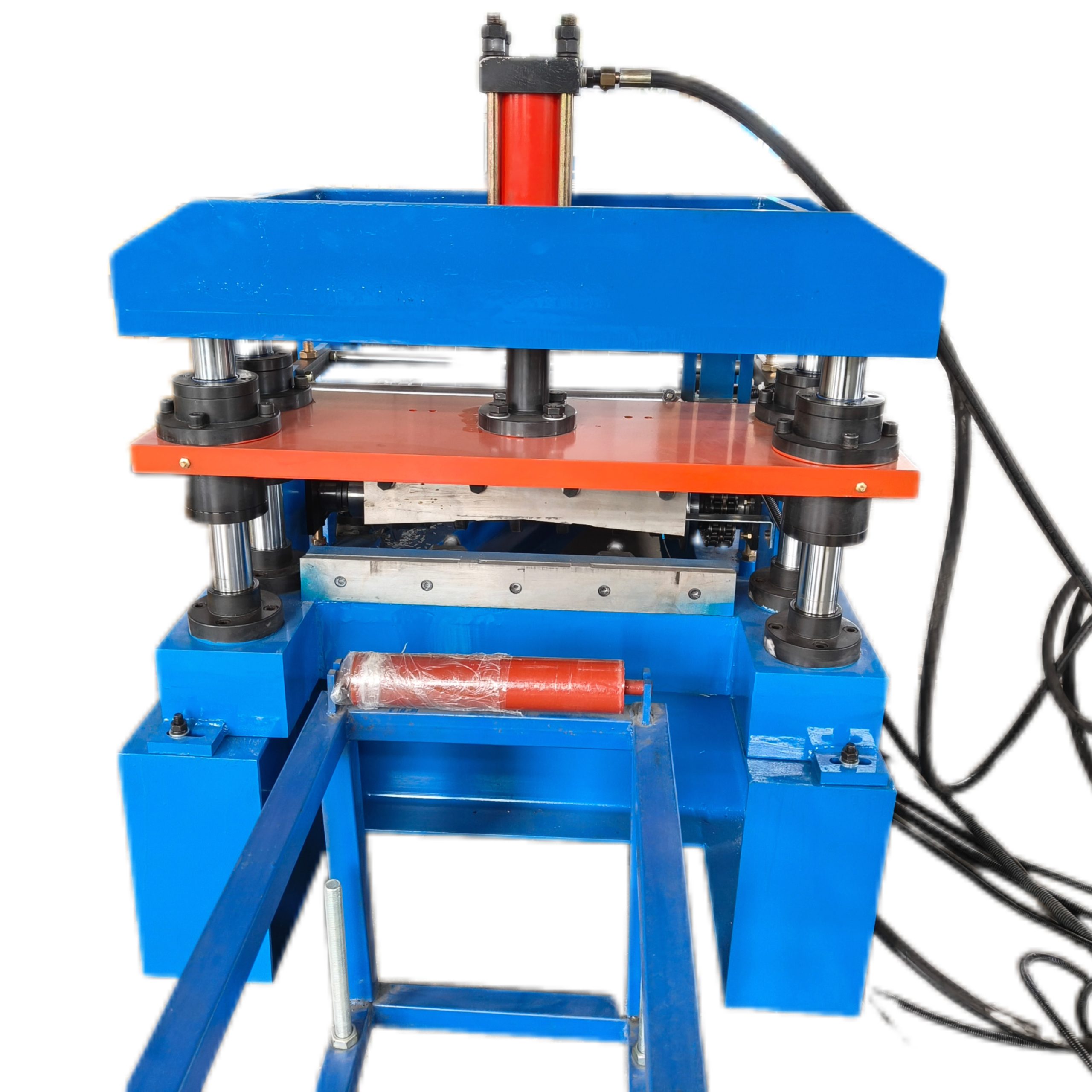

| 3 | Hydraulic Cutting system | set | 1 |

| 4 | PLC control station | set | 1 |

| 5 | Product receive table | set | 1 |

| 6 | Spare parts | set | 1 |

The technical specifications of the Standing seam roofing sheet machine:

| Item | Name | Specifications |

| 1 | Raw material | GI&PPGI |

| 2 | Raw material thickness | 0.4-10.6mm |

| 3 | Decoiler | 3T |

| 4 | Felt device | Available |

| 5 | Roller station | 20stations |

| 6 | Roller material | 45# steel |

| 7 | Shaft diameter | 70mm |

| 8 | Shaft material | 45# steel |

| 9 | Transmission | By double chain, with chain cover |

| 10 | Motor power | 5.5kw |

| 11 | Machine frame | 350H steel |

| 12 | Cutting type | Hydraulic cutting |

| 13 | Hydraulic power | 3kw |

| 14 | Cutting blade material | Cr12 quenched |

| 15 | Cutting tolerance | +/1mm |

| 16 | Control system | Delta/ Siemens PLC |

Some details of the Standing seam roofing sheet machine: