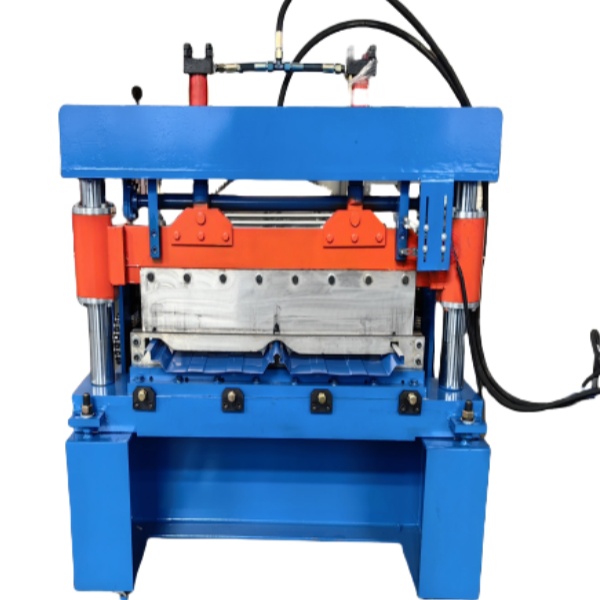

Standing seam roofing sheet machine is a specialized equipment used for producing vertical seam roof tiles. Standing seam roof tiles have good waterproof, thermal insulation and thermal insulation properties, which can effectively protect buildings from external environmental influences. In addition, its metal material also has a long service life and strong weather resistance.

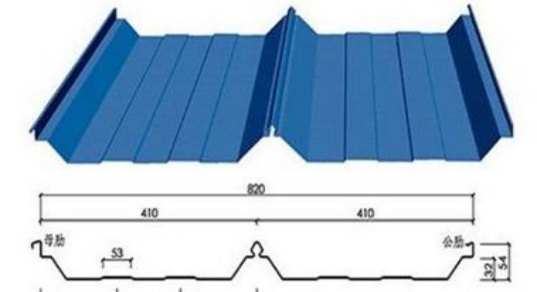

The pictures for the finished product:

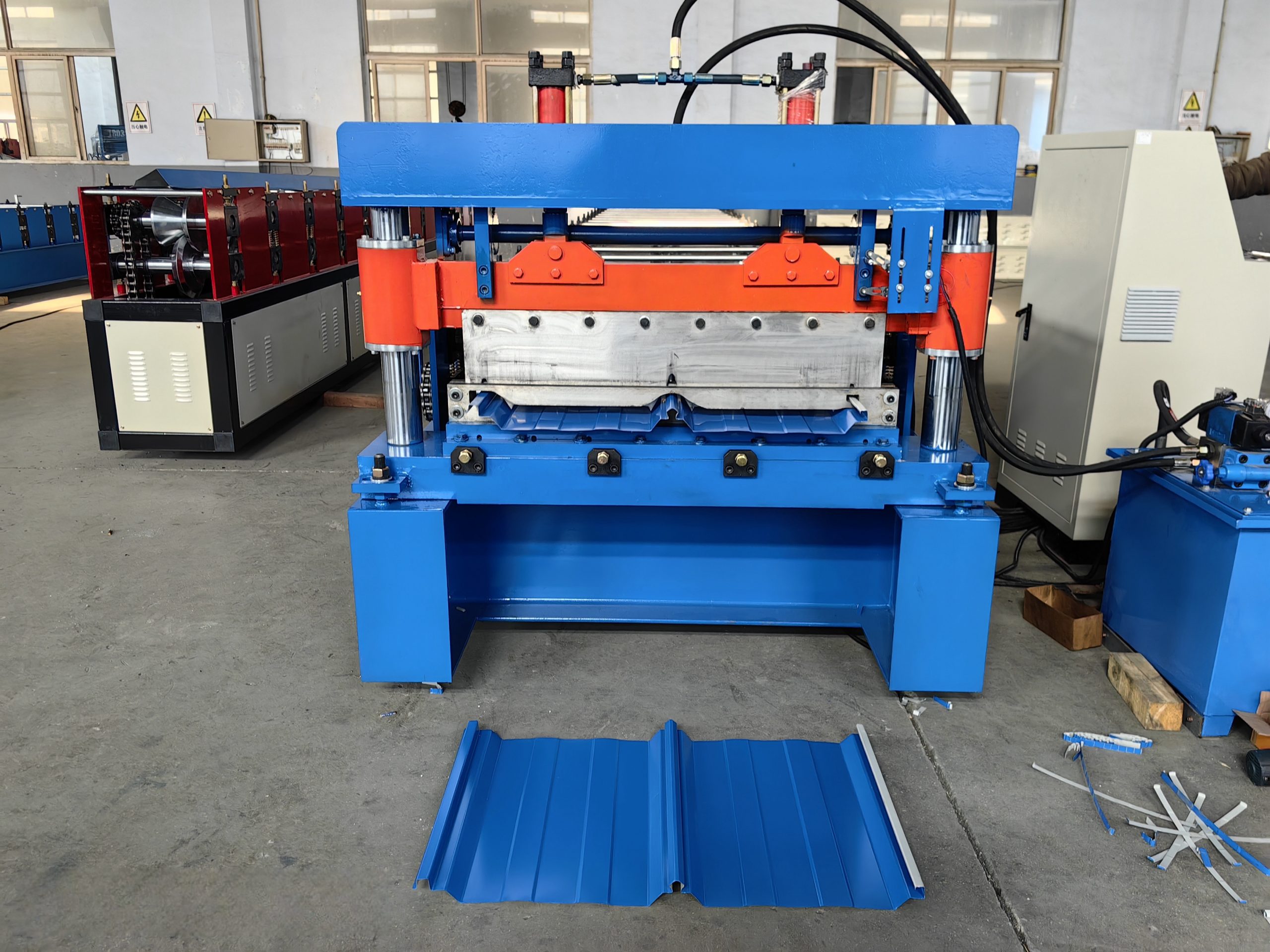

Production process:

Uncoiler-Feeding material into machine→Roll forming→hydraulic cutting→ Products receiving

Packing list of the Standing seam roofing sheet machine:

| No. | Name | Quantity |

| 1 | Manual/hydraulic Decoiler | 1 set |

| 2 | Main roll former | 1 set |

| 3 | Control system | 1 set |

| 4 | Hydraulic system | 1 set |

| 5 | Product Run-out table | 1 set |

The technical specifications of the Standing seam roofing sheet machine:

| Item | Name | Specifications |

| 1 | Raw material | GI&PPGI |

| 2 | Raw material thickness | 0.8-1.2mm |

| 3 | Decoiler | 5T |

| 4 | Felt device | Available |

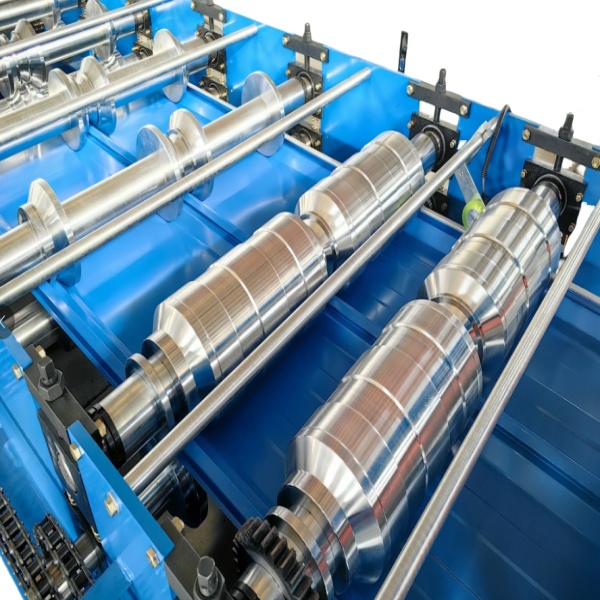

| 5 | Roller station | 20stations |

| 6 | Roller material | 45# steel |

| 7 | Shaft diameter | 70mm |

| 8 | Shaft material | 45# steel |

| 9 | Transmission | By double chains |

| 10 | Motor power | 5.5kw |

| 11 | Machine frame | 350H steel |

| 12 | Cutting type | Hydraulic cutting |

| 13 | Hydraulic power | 3kw |

| 14 | Cutting blade material | Cr12 quenched |

| 15 | Cutting tolerance | +/1mm |

| 16 | Control system | Delta/ Siemens PLC |

The function of the Standing seam roofing sheet machine:

1. Efficient production of roof tiles:

The Standing seam roofing sheet machine can quickly process metal sheets (such as galvanized sheets, aluminum zinc coated sheets, etc.) into the desired roof tile shape through rolling forming technology. This type of equipment is usually equipped with an automatic control system, which can achieve automated production and improve production efficiency.

2.Improve product quality and consistency:

The equipment adopts advanced rolling forming technology to ensure that the size, shape, and height of each roof tile are consistent, the surface is smooth, and the quality is stable. This consistency helps to reduce errors during installation and improve the overall quality and aesthetics of the roof.

3.Diversified design and customization:

TheStanding seam roofing sheet machine can adjust the size, shape, and material of tiles according to customer needs to meet different architectural styles and design requirements. For example, it can produce roof tiles with different waveforms, widths, and thicknesses.

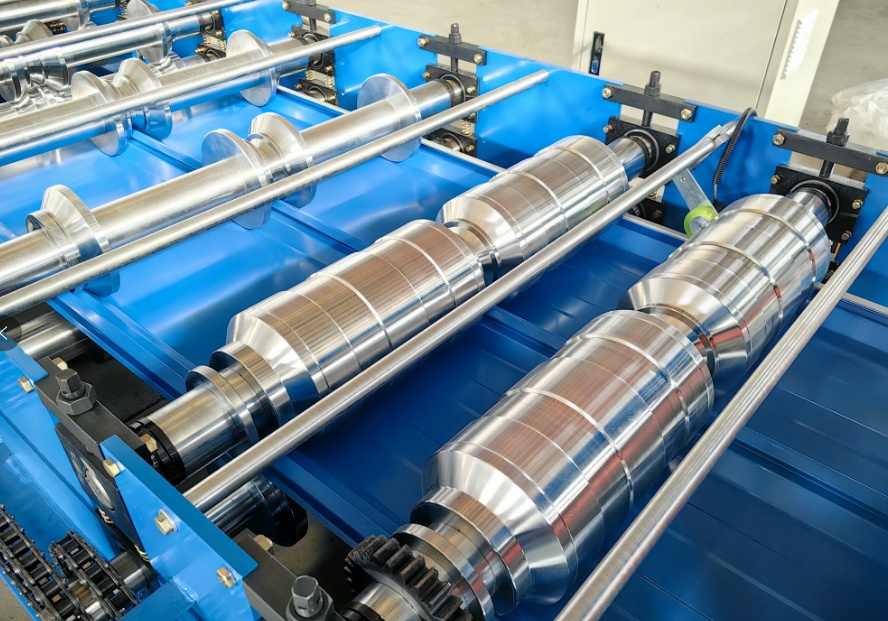

Some details of the Standing seam roofing sheet machine: