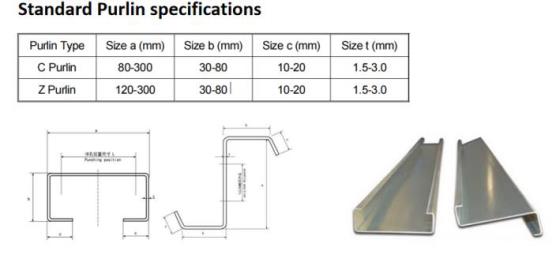

The Standard 80-300mm CUZ Purlin Machine is an advanced industrial equipment designed for efficient production of high-quality CUZ purlins. With precision engineering and a wide range of capabilities, this machine effortlessly shapes metal sheets into precise and uniform CUZ purlin profiles, accommodating sizes from 80mm to 300mm. Its versatility allows for various specifications of purlins, meeting diverse construction needs. The Standard 80-300mm CUZ Purlin Machine ensures consistent and accurate results, optimizing production efficiency. It is an essential tool for manufacturers aiming to deliver reliable and durable CUZ purlins for commercial, industrial, and residential buildings, providing superior structural support with versatility and precision.

Purlins carry the roof deck or sheathing loads and are supported by large rafters and building walls, steel beams, etc. In comparison to closely spaced rafters, the use of purlins is common in pre-engineered metal construction systems and both the ancient post-and-beam and newer pole construction methodologies for frame construction.

As the widely usages of C purlin in daily life, we design the fully automatic C purlin rolling machine, as to the automatic stacker it is optional;

And then, people tend to use C and Z steel purlins on their steel framed buildings, in order to provide an efficient, lightweight and cost efficient roofing, cladding and walling support system (Purling and girt system).

Fully automatic C purline rolling forming machine with stacker:

Why you need stacker?

- When planning to use the higher speed rolling forming machine, workers can not handle so higher speed.

- When you handling the thickness beyond 3.0mm, or mostly heavy duty work.

- When the worker salary is higher, the stacker can help you save workers one or two.

- When the production is so high, stacker can help you do the purline orderly.

How to adjust the machine when thickness changes? For example from 1.5 to 3.0mm.

If the thickness of the replacement material does not exceed 0.5mm, such as changing from a material with a thickness of 1.5mm to a material with a thickness of 1.8mm, there is no need to adjust the machine. If the thickness change exceeds 0.5mm, it is necessary to adjust the gap between the upper and lower rows of forming rollers of the machine. If the thickness increases, the gap needs to be increased, and if the thickness decreases, the gap needs to be reduced.For example from 1.5 to 3.0mm, you need to increase the gap between upper roller and lower roller of all the stations. Use a ruler to measure the gaps and make it increase by 1.5mm.