Single Peak Floor Decking Forming Machine is a mechanical equipment specifically used for producing single peak floor support plates. The unimodal floor slab has a unique waveform structure and is usually made of high-quality steel such as galvanized steel sheet processed by cold bending forming technology. This equipment processes raw materials into unimodal floor slabs that meet building requirements through a series of precise mechanical operations, providing an efficient and convenient floor support solution for construction.

The profile drawing:

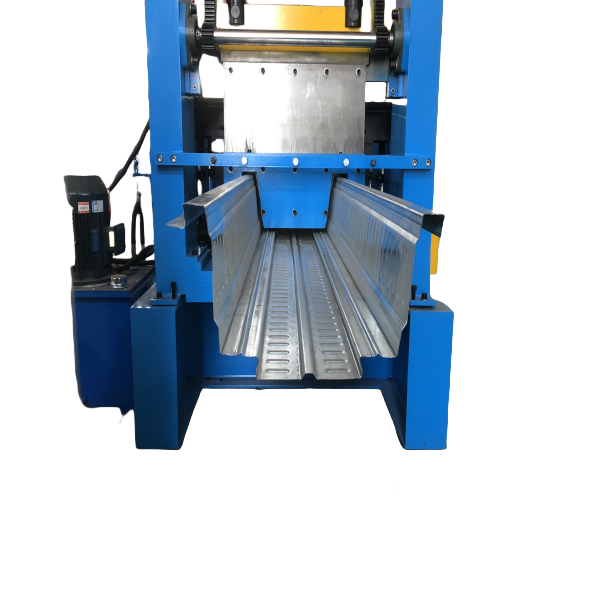

The pictures for the finished product:

Production process:

Uncoiler-Feeding material into machine→Roll forming→hydraulic cutting→ Products receiving.

Packing list of the Single Peak Floor Decking Forming Machine:

| No. | Name | Quantity |

| 1 | Manual/hydraulic Decoiler | 1 set |

| 2 | Main roll former | 1 set |

| 3 | Control system | 1 set |

| 4 | Hydraulic system | 1 set |

| 5 | Product Run-out table | 1 set |

The technical specifications of the Single Peak Floor Decking Forming Machine:

| Item | Name | Specifications |

| 1 | Raw material | GI&PPGI |

| 2 | Raw material thickness | 0.7-1.5mm |

| 3 | Decoiler | 5T |

| 4 | Felt device | Available |

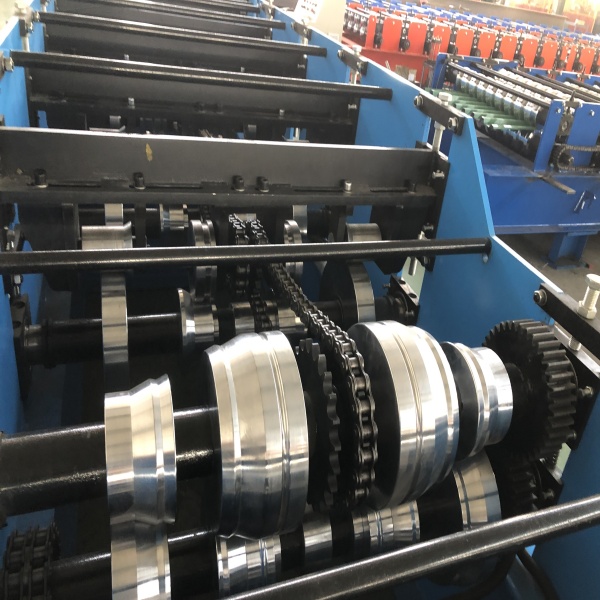

| 5 | Roller station | 34stations |

| 6 | Roller material | 45# steel |

| 7 | Shaft diameter | 85mm |

| 8 | Shaft material | 45# steel |

| 9 | Transmission | By double chains |

| 10 | Motor power | 5.5kw |

| 11 | Machine frame | 400H steel |

| 12 | Cutting type | Hydraulic cutting |

| 13 | Hydraulic power | 5.5kw |

| 14 | Cutting blade material | Cr12 quenched |

| 15 | Cutting tolerance | +/1mm |

| 16 | Control system | Delta/ Siemens PLC |

The function of the Single Peak Floor Decking Forming Machine:

1.Efficient production:

The Single Peak Floor Decking Forming Machineadopts advanced production technology and automation control technology, which can achieve efficient and continuous production operations. This not only improves production efficiency, but also reduces production costs, providing more economical and practical floor slab products for construction projects.

2. Precision processing:

The equipment is equipped with high-precision processing devices and detection systems, which can ensure the precise size and regular shape of the single peak floor slab produced. This helps to improve the overall quality and aesthetics of the building floor, meeting the high requirements of modern architecture for precision and aesthetics.

3.Flexible adaptation:

The Single Peak Floor Decking Forming Machinecan adjust production parameters and waveform structures according to different building and design requirements. This enables the produced floor slabs to flexibly adapt to various building scenarios and styles, meeting diverse building needs.

4.High quality materials:

Equipment usually uses high-quality steel such as galvanized steel plates as raw materials, which have good corrosion resistance and load-bearing capacity. The unimodal floor slabs produced have excellent durability and stability, and can withstand long-term floor loads and external environmental influences.

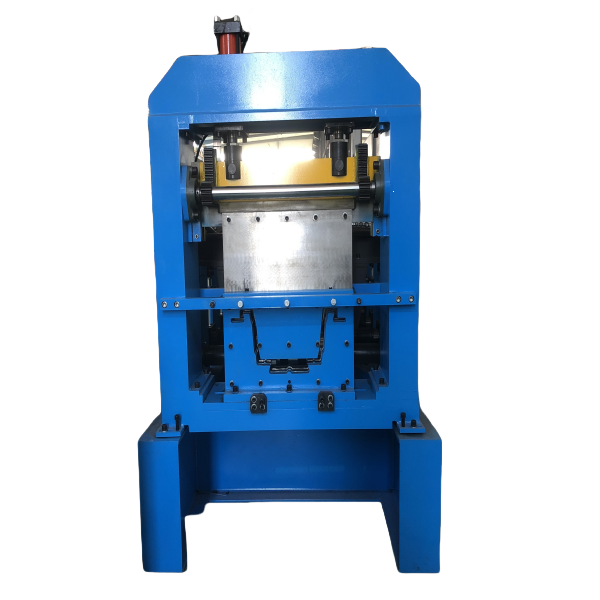

Some details of the Single Peak Floor Decking Forming Machine: