Sandwich Panel Sheet Forming Machine – the ultimate solution for producing high-quality and efficient sandwich panels. This advanced equipment excels in precision and speed, ensuring seamless and accurate forming of sandwich panels with various core materials. Its user-friendly controls and state-of-the-art technology guarantee smooth operation and consistent output. The machine’s versatility accommodates different panel thicknesses and designs, catering to diverse construction needs. Elevate your panel production with this reliable and robust machine, bringing cost-effectiveness, energy-efficiency, and top-notch quality to your manufacturing process. Experience superior sandwich panels and streamline your construction projects with ease.

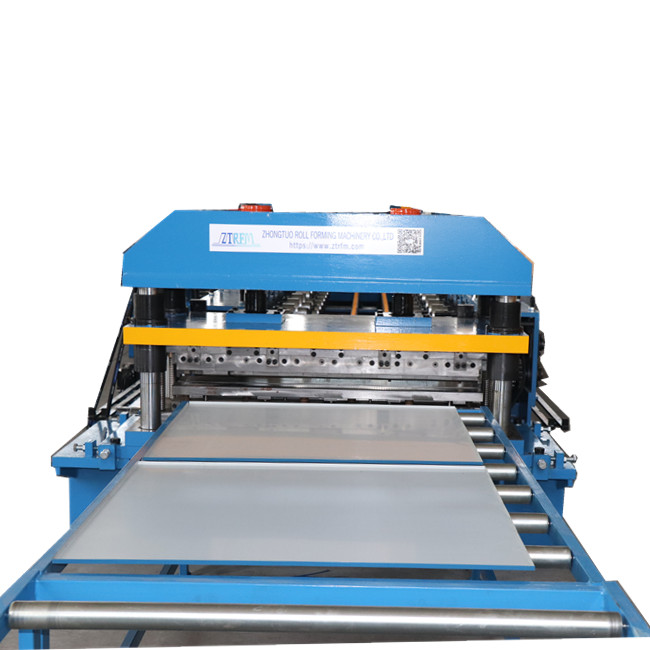

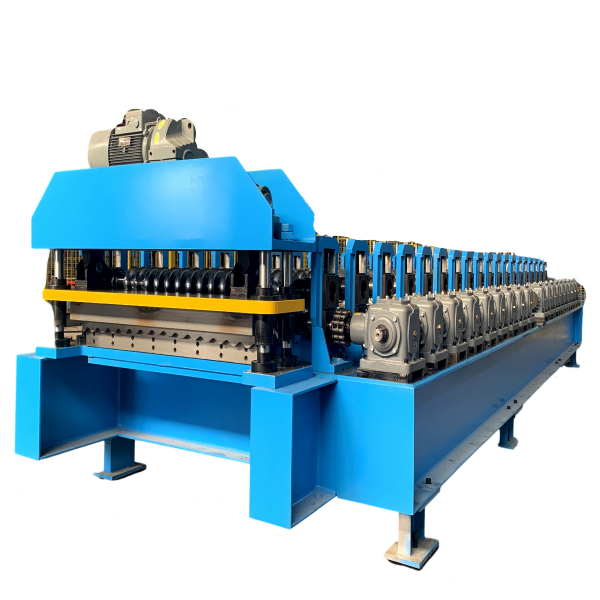

Sandwich Panel Sheet Forming Machine

We have one new design machine, which can be used either for making sandwich panel bottom sheet and also could be used to make width Adjustable Clean-room Wall Panels in batch fully automatically. Sandwich panel sheet forming machine make up and bottom sheets for insulated Sandwich Panel.

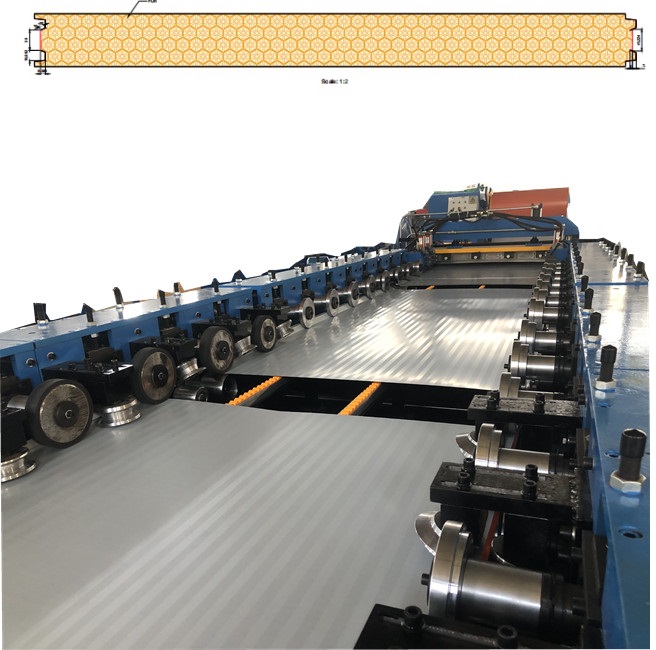

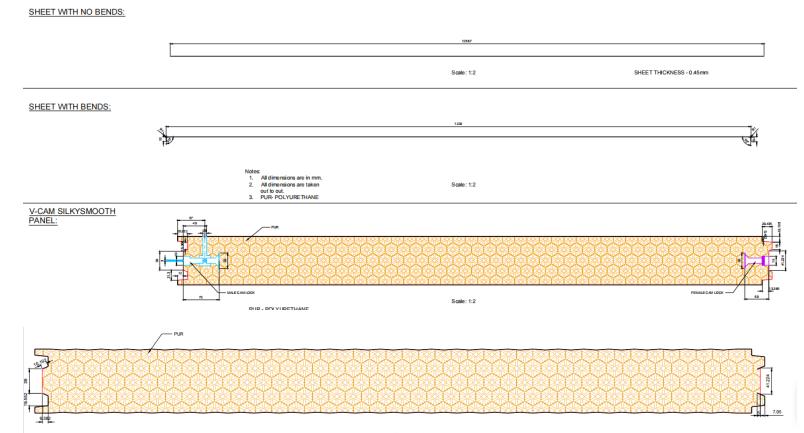

Discontinuous panel filled polyurethane used for insulated wall and roof building panels, garage doors, entry doors, and refrigeration coolers. That means first make up and bottom sheet, then take sheets to discontinuous Insulated Sandwich Panel Lines to fill in polyurethane for sandwich panel. Here are some popular drawing profiles for your reference:

As to the profile with metal embossing or without, that depends on you. The embossing rollers are adjustable.

Finished product pictures:

For those two profiles both could be made by one machine, you can choose to with bending or without.

Sandwich Panel Sheet Forming Machine

Equipment composition of Sandwich Panel Sheet Forming Machine:

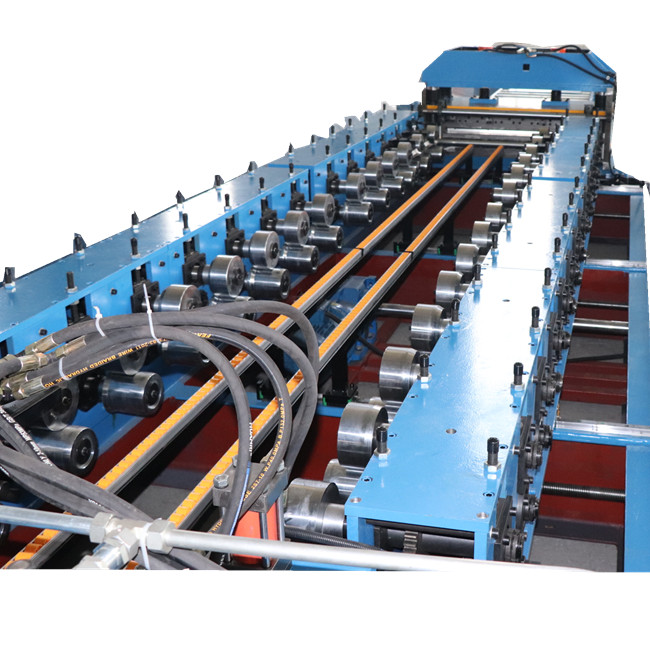

The equipment consists of the following parts: a 6-ton hydraulic automatic feeding rack with a trolley, a film covering device, a guide device, a punching device, a punching device, a cutting device, a forming system (horizontal movement), a cutting and folding device (U-shaped), a material supporting device, a hydraulic system, and an electric control system

Technical parameters

Plate specification and material: ordinary colored steel coil, strength: 235-345Mpa;

Thickness: Color coated board 0.4-0.8mm, unfolded (see board shape diagram for details)

Forming speed around 20m/min (adjustable)

Power requirements: Main motor power: 7.5kw motor, hydraulic motor power: 5.5KW with air cooling

Forming system: The reinforcement can be pressed or not (0.4-0.8mm), with three types of two sets of rollers

Hydraulic loading rack can load up to 8 tons

Maximum loading capacity of mechanical loading rack: 6 tons

Host structure H350x175 type steel chassis with 200mm leg height and 20mm single side double wall panel overall structure (see machine similar diagram)

Control system: Mitsubishi PLC and touch screen, or Yaskawa frequency converter,

Siemens PLC and touch screen

Cutting method: fixed length cutting after forming

Power supply requirement: 380V/50HZ/3Phase

Overall longitudinal sliding mesh protective cover for safety protection

Machine color blue+yellow

Sandwich Panel Sheet Forming Machine advantages:

- Width adjustable PLC control.

- After adjusting some rollers, two profiles could be made.

- With embossing and without adjustable.

- With filming device.

- With automatic decoiler, easy to work.

- Cut the corner and make the box shape rolling forming.

- Lots of side rollers to shape the corner also with the rubber cover and then it will not damage the surface of the coil.

Sandwich Panel Sheet Forming Machine working videos for your reference.