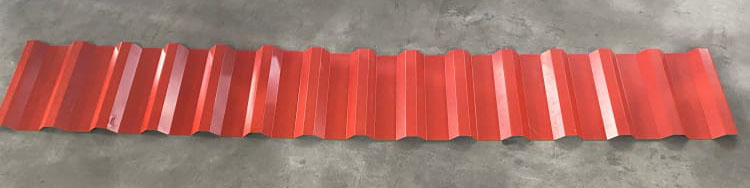

R101 Trapezoidal Sheet Roll Forming Machine, a state-of-the-art solution for efficient and precise trapezoidal sheet production. This advanced equipment is designed to meet the demands of modern roofing and construction industries. Its robust construction ensures durability and longevity, providing a reliable performance for years. The R101 Trapezoidal Sheet Roll Forming Machine offers adjustable settings, allowing easy customization for different sheet profiles. With its user-friendly interface and safety features, it guarantees a smooth and secure operation. Experience seamless roll forming with high accuracy and uniformity, boosting productivity and ensuring top-quality trapezoidal sheets for your projects. Elevate your production capabilities with this cutting-edge roll forming machine.

R101 trapezoidal roof tile making machine ibr roof sheet machine popular in Mexico market

Stable Transmission: Double chain and gear drive,keynote rollers design.

Easy Operation:Only need to set orders on the PLC control station,very easy operation .

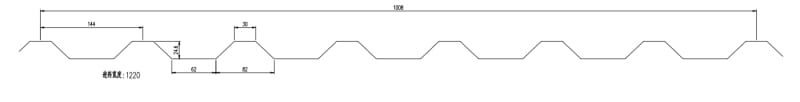

Profile drawing for reference:

Trapezoidal roofing sheet has many different shapes,usually different countries have its own popular design ,we can customize the machine as customers’ demand,R101 roofing sheet is most popular in Mexico market.

Processing Flow

Uncoiling → Feeding material into machine →Roll forming → Auto cutting →Products receiving

table

table

R101 Roofing Sheet Roll Forming Machine Hot Sale To Mexico | |

Raw Material | PPGI,PPGL |

Material Thickness:24/26 Gauge (0.4-0.6 Mm) | |

Machine Frame | 350mm H Beam Structure, With 18mm Welded Steel Middle Support Plate. |

Roller Material | 45# steel, chromed on the surface |

Forming Stations | Roller Stations :21 Rows |

Diameter Of Shafts | Φ80mm Solid |

Material Of Shafts | High Grade 45#,With Heat Treatment |

Forming Speed | 15 M/Min |

Voltage | 380v/50hz/3p (As Requested) |

Transmission Way | By 1 Inch Chain (Double Chains) |

Main Motor | 5.5 KW |

Cutting Blade Material | Gcr12 quenched treatment |

Cutting Type | hydraulic post cutting |

Driving Method | By pillar type Cylinder |

Feeding Device

Hydraulic Cutting Device

We use four pillars cutting system structure, it can make sure the cutting stable

PLC control system

PLC brand:Delta(Taiwan) PLC, and transducer and touched screen

● Encoder brand:Omron

● Electrical components:Schneider

●Operating language:English and Chinese(or as requested) You can set the orders on this part,changing product length and quantity,it is really easy to operate,and there are aviation plugs to make it much easier to install the machine while it arrived.