Floor Decking Tile Roll Forming Making Machine is a device used for producing profiled steel sheets for construction, mainly used to process metal sheets into floor support plates with specific cross-sectional shapes.

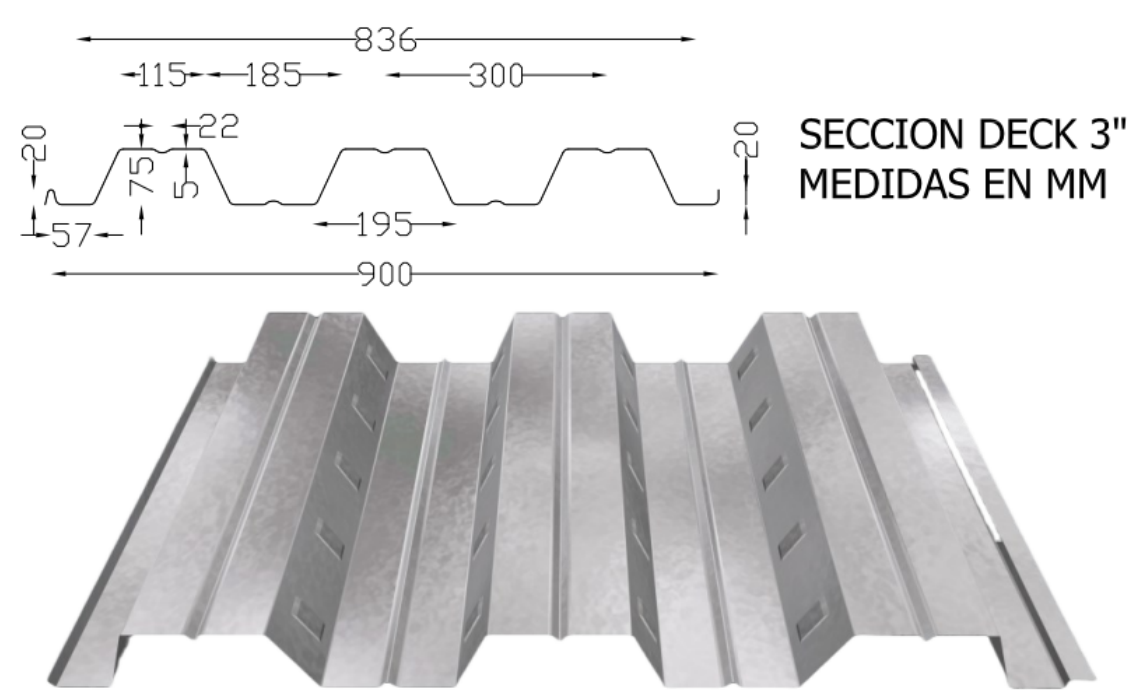

Floor Decking Tile, also known as profiled steel plate, load-bearing plate, etc., is a corrugated steel plate formed by rolling and cold bending galvanized steel plate, with a cross-section of V-shaped, U-shaped, trapezoidal or similar shapes. Its greatest function is to be used as a permanent template. This Floor Decking Tile has strong load-bearing capacity, and due to its open design, its fire resistance performance is better than that of general floor tiles.

Profile Drawing:

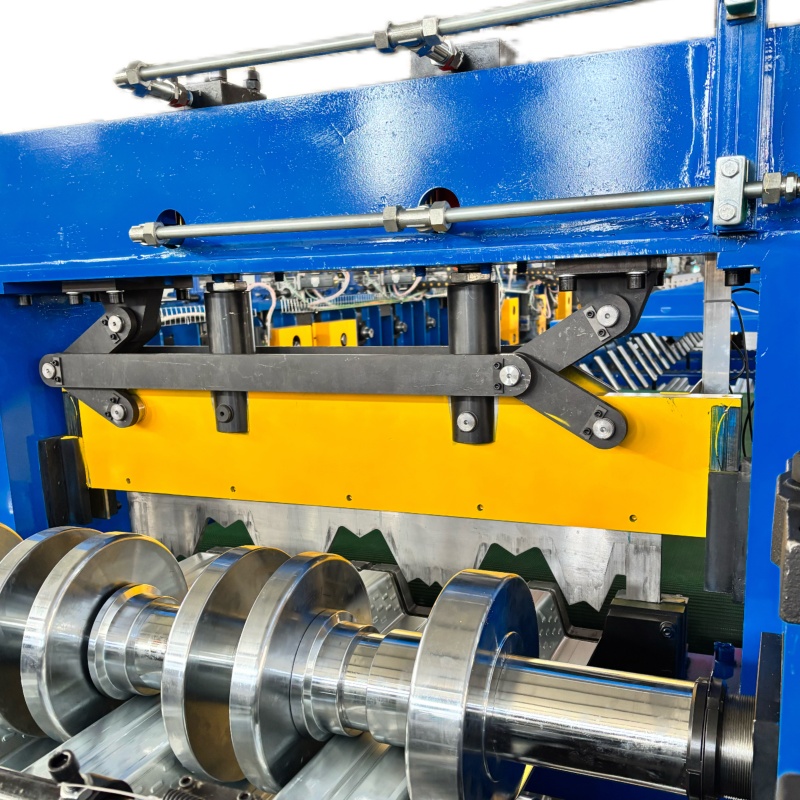

Here are photos of Metal Floor Decking Tile Roll Forming Making Machine:

Here are photos of Metal Floor Decking Tile Roll Forming Making Machine:

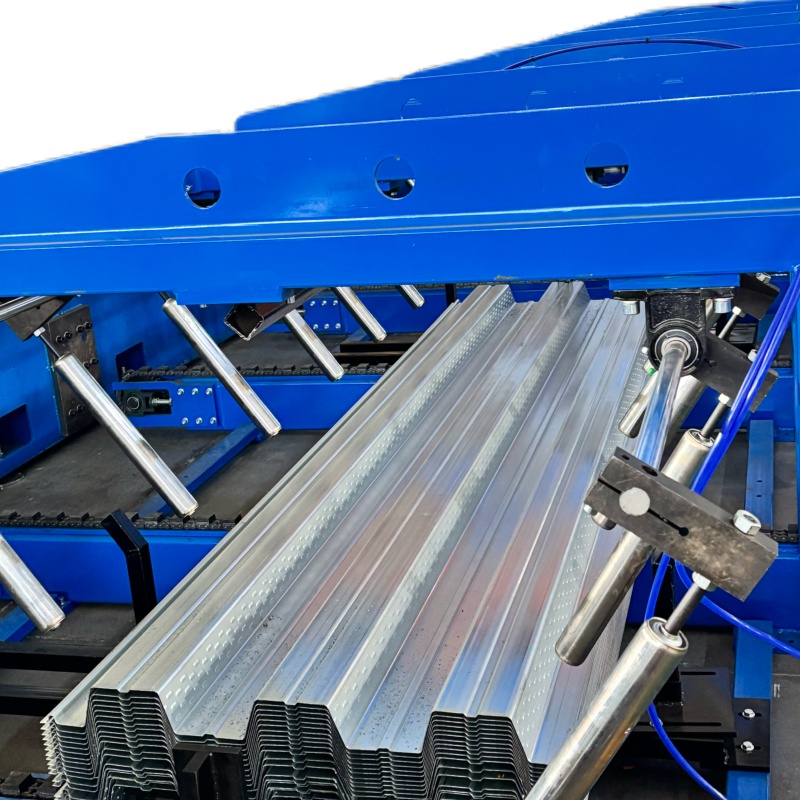

Apply photos of Metal Floor Decking Tile Roll Forming Making Machine:

Apply photos of Metal Floor Decking Tile Roll Forming Making Machine:

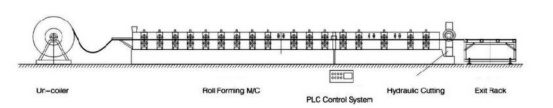

working flow of Metal Floor Decking Tile Roll Forming Making Machine:

Main components of Metal Floor Decking Tile Roll Forming Making Machine:

| Item | Description of Item | Unit | Quantity |

| 1 | Hydualic decoiler | set | 1 |

| 2 | Main roll forming machine | set | 1 |

| 3 | Hydraulic Cutting system | set | 1 |

| 4 | PLC control station | set | 1 |

| 5 | Product receive table | set | 1 |

| 6 | Spare parts | set | 1 |

The following is detailed introduction of each main elements of this Metal Floor Decking Tile Roll Forming Making Machine:

Part 1: Hydraulic decoiler

Part 2: Main roll forming machine

Part 2: Main roll forming machine

1.Shaft material:45# STEEL with quenched and tempering

2.Shaft diameter:95mm, solid shaft

3.Roller material: 45# steel

4.Roller station: 28stations

5.Work speed:About 0-20m/min

6.Machine body:350H steel welded

7.Bearing :Chinese famous brand Harbin

8.Work power:5.5 kw

9.Transmission :By double chain

10.Voltage:380V,50Hz,3 phase (customize)

Part 3:Hydraulic cutting system

1.Work type:Hydraulic

2.Motor power:5.5 kw

3.Cutting blade material :GB-Cr12 mould steel with quenched treatment

4.Cooling system:By fan

Part 4: PLC Control system

1.PLC and Touch screen:Delta, wold famous brand

1.PLC and Touch screen:Delta, wold famous brand

2.Electrical components:Schneider

3.Operating language:English and Chinese(or as requested)

4.Function:You can set the orders on this part,changing product length and quantity,it is really easy to operate,and there are aviation plugs to make it much easier to install the machine while it arrived.