Cut length machine is mainly used for the continuous straightening of cold and hot rolled strip coils with thickness of 0.3-5mm, and the transverse shear steel plate whose length is less than 2000mm, and then stacking is neat, which has the characteristics of high precision and wide adaptability.

Production process:

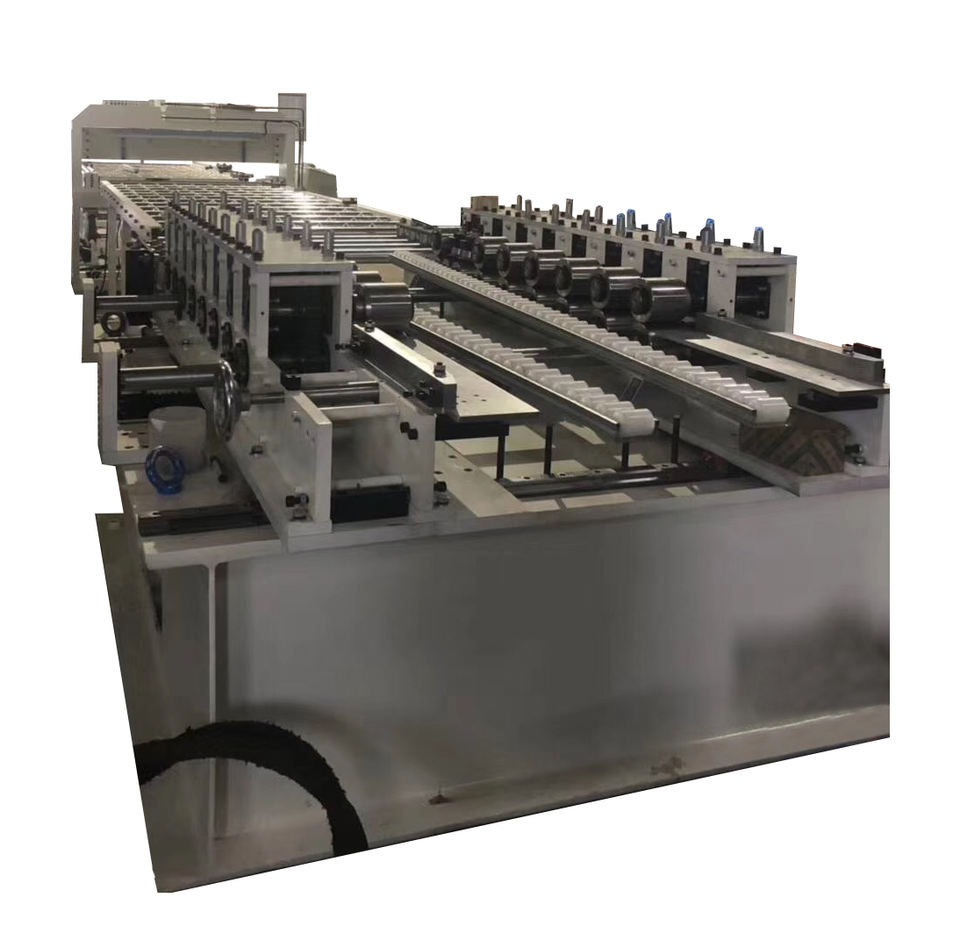

From right to left, they are Uncoiler + coil car—Press device with side guide device—straightener —Cutting machine—receivable table

Packing list of the metal cut to length machine:

| No | Name | Quantity |

| 1 | Hydraulic entry coil car | 1unit |

| 2 | Hydraulic De-coiler | 1unit |

| 3 | Press and pinch device | 1unit |

| 5 | Loop | 1unit |

| 6 | Side guide device | 1unit |

| 7 | Straightener machine | 1unit |

| 8 | Cutter | 1unit |

| 9 | Stacker | 1unit |

| 10 | Hydraulic system | 1 sets |

| 11 | Electrical control system | 1 sets |

The function of the Angle with punched holes Roll Forming Machine:

1. Efficiency: Able to quickly process metal coils into flat sheets of the required length.

2.High precision: The size of the cut sheet metal is precise, meeting the requirements of high precision.

3.High degree of automation: Modern horizontal cutting equipment is usually equipped with an automated control system, which is easy and reliable to operate.

Some details of the Angle with punched holes Roll Forming Machine: