Light Steel Framing Machine, the ztrfm forming of precision and efficiency in light steel frame production. This cutting-edge equipment is designed to meet the demands of the construction industry, delivering high-quality and lightweight steel frames with utmost accuracy. The precision-engineered rollers ensure uniform shaping, resulting in sturdy and dimensionally accurate frames for various applications like residential and commercial buildings. With user-friendly controls and adjustable settings, the machine allows for easy customization, accommodating different frame sizes and profiles. Built with top-quality materials, our Light Steel Framing Machine guarantees durability and reliable performance, optimizing your production and delivering outstanding results for your construction projects. Experience seamless light steel frame production with this high-quality roll forming machine and revolutionize your construction efficiency.

light steel frame villa roll machine-using C channel and U channel as the combination is designed to make the 6 layers bulding by one machine. The material thickness could be from 0.8 to 2.0mm. The width adjustment could be from 89 to 300mm and all the operation could be finished with in the computer. The PLC control system is open socurce, it can accpet all design software programme. In the following part, I will take the drawing for example to show more details of the machine and explain how it works.

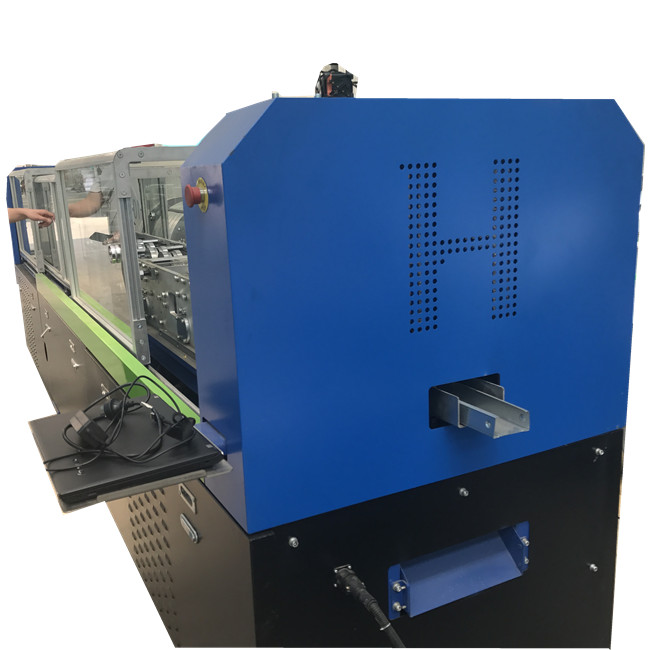

Here is the Magic version light frame villa rolling machine picture for your reference:

| PLC | PC control | |

| Changeable distribution box | 1 (installed in the middle of the rack) | |

| External controller | 1 (can facilitate the advancement and retreat in the production process and debugging process) | |

| Main accessories origin | PLC (Panasonic, Japan), relay (Schneider, France), proximity switch (Ortonix, Korea) | |

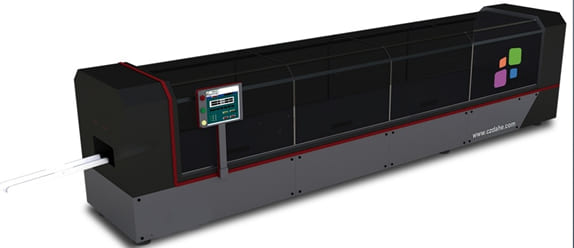

| Printer | One-piece inkjet (single nozzle, fixed side waist high spray) | |

| power system | Servo motor 22KW+ curved bevel gear reducer | |

| Mian hydraulic | Hydraulic station power 11KW + air cooling | |

| Fuel tank capacity 200 liters | ||

| Small hydraulic station | Hydraulic station power 3.75kw + heat sink; fuel tank volume 30 liters (underline flange mold) | |

| Main parts origin | Solenoid valve oil research and development | |

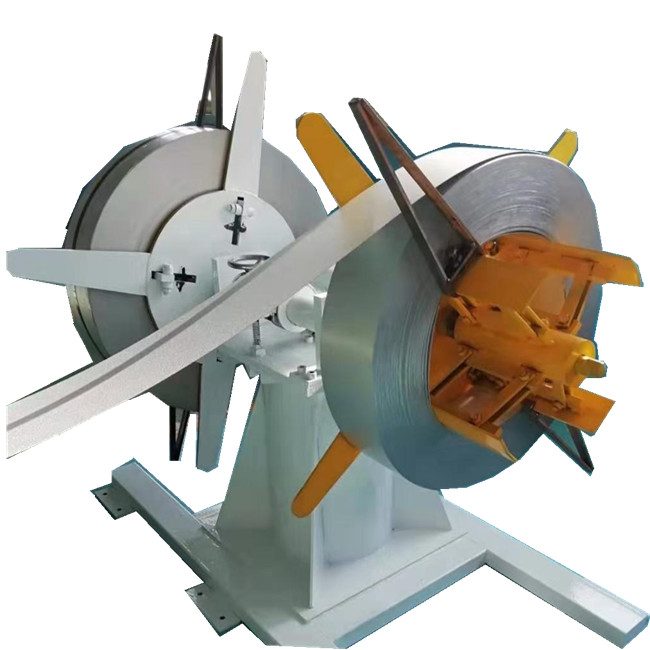

| Supporting weight: 5 Ton | ||

| Expansion | Hand rail | |

| The center of the four links is outwardly supported | ||

| Driven | Motor drive, automatic discharge | |

| Supporting length 12 meter, it has two parts, one is for 6 meter and another is for 3 meters | ||

| Metahod | The frame body is welded with angle steel and angle steel, and the surface is loaded with rollers. | |

| Roller | Material:Gcr12 | |

| Processing technology: after CNC machining, heat treatment to HRC58-60, and then fine car | ||

| Shaft | Material: 40Cr | |

| Processing technology: after CNC machining, quenching and tempering treatment HRC28-32, and then fine plating | ||

| Weight | The weight of the whole machine is about 9 tons. | |

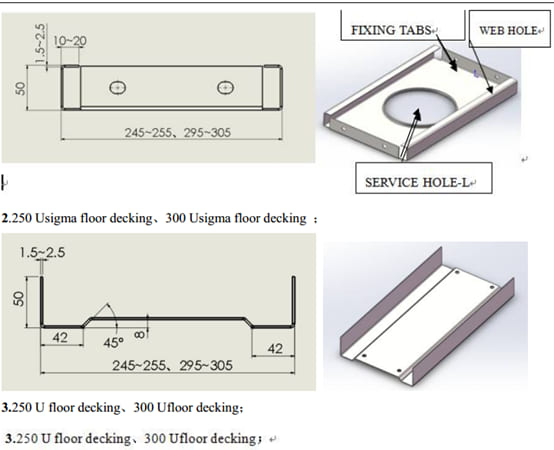

Here are some pictures shows the finished products of Magic version light frame villa rolling machine:

This type design of Magic version light frame villa rolling machine in some degree, it can save lost of cost in inverstment. It is easy for installaion and more universial. Please check our other designs in our websites. If you have any problem, please contact us at any time.