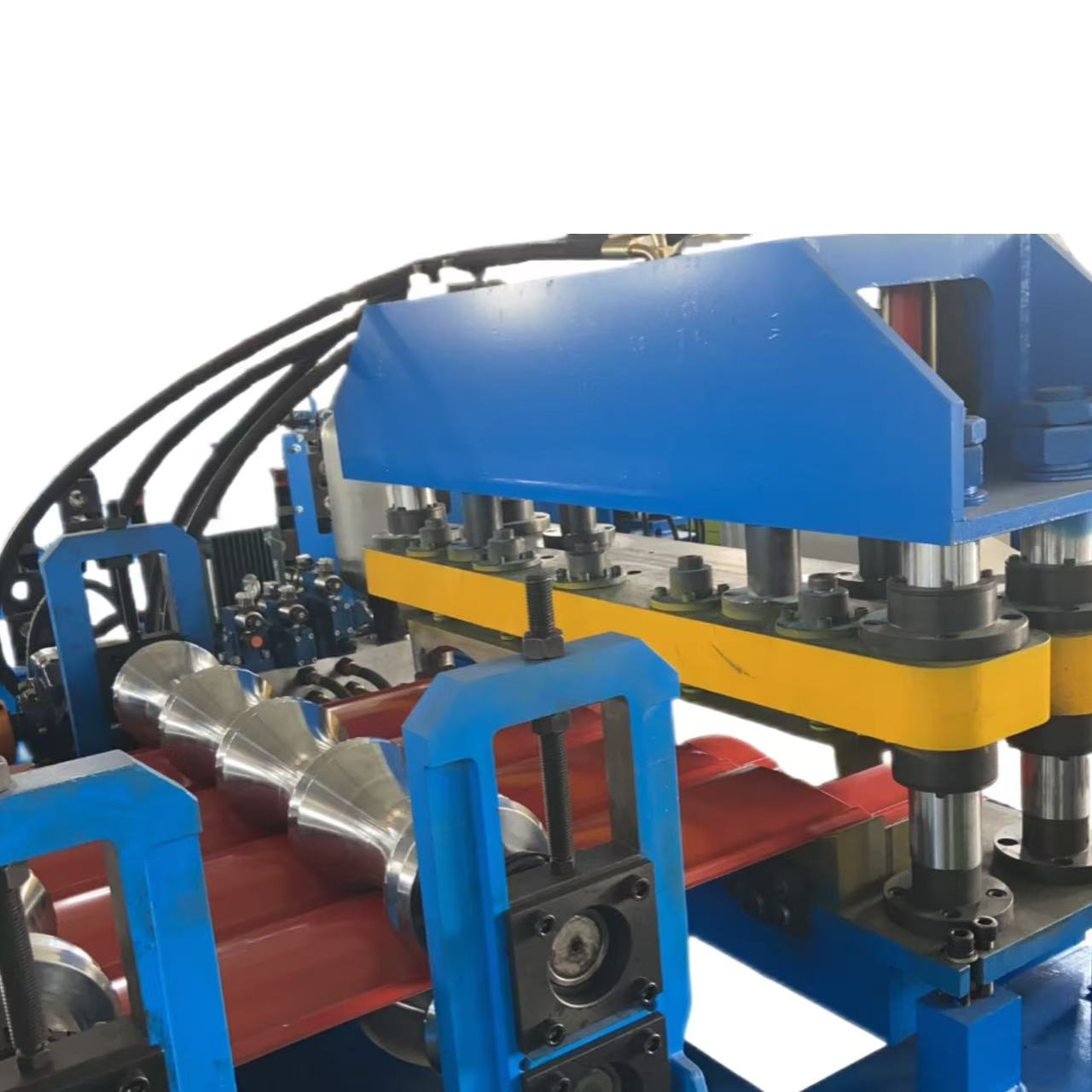

Hydraulic cutting metal glazed roofing tile machine

The metal glazed roofing tile machine is a device used for building houses, which uses galvanized steel plates or colored steel plates or aluminum plates as raw materials. The products produced are used to build the exterior roof and wall panels, as well as interior decorative panels or ceilings of houses, to increase the beauty and durability of the roof or walls. The surface of the finished product produced by the glazed tile machine production line is smooth, flat, and scratch free, making it easy to install during construction.

The characteristics of the metal glazed roofing tile machine mainly include the following aspects:

1. Good molding effect:

The metal glazed roofing tile machine can produce glazed tiles with beautiful appearance, antique elegance, and exquisite and unique shape through rolling and stamping. These tiles are widely used for garden style factories, tourist attractions, pavilions, hotels, villas, exhibition halls, resorts, and homes, as well as outdoor decoration.

2. High production efficiency:

The metal glazed roofing tile machine adopts advanced production technology and equipment, which can efficiently produce high-quality glazed tiles. The production process is highly automated, reducing manual operations and improving production efficiency and product quality.

3. Wide applicability:

The glazed tiles produced by themetal glazed roofing tile machine have excellent waterproof performance, durability, wide climate adaptability, rich and colorful color selection, and easy maintenance. These characteristics enable glazed tiles to maintain good performance under various climatic conditions and are widely used in various architectural and decorative occasions.

Drawing Profile showing:

The pictures for the finished product:

Machine Parameters:

| Items | metal glazed roofing tile machine | |

| Material | Thickness | 0.4-0.6mm |

| Coil width | 1000mm | |

| Yield Strength | 235 Mpa | |

| Material | Aluminium Coils, PPGI, Color Steel, GI. | |

| Decoiler / Uncoiler | Uncoiler Type | Manual or Hydraulic or Auto Type |

| Coil Width | Max. 1250mm | |

| I.D | 508-610mm | |

| O.D | Max. 1500mm | |

| Flat Sheet Rolling Mill | Forming Stations | 14 Stations ( Depend on Profiles ) |

| Roller material | 45# steel coated with 0.05mm hard chrome | |

| Diameter of shaft | 80mm | |

| Shaft material | High grade 45# steel | |

| Drive type | Gearbox transmission | |

| Machine structure | Cast iron archway | |

| Forming speed | 5-8m/min | |

| Main power | 7.5KW | |

| Step Pressing Device | Pressing Type | Hydraulic type pressing |

| Pressing Mould | Cr12 Mov steel, HRC58-62 | |

| Automatic Cutting Device | Cutting type | Hydraulic cutting |

| Cutting Die Material | Cr12Mov steel, HRC58-62 | |

| CuttingTolerance | 10m+/-1.5mm | |

| Encoder | OMRON Brand | |

| PLC Electrical Control Board | PLC | Delta from Taiwan |

| Inverter | Delta | |

| Touch screen | Delta | |

| Operation type | Touching screen & Buttons | |

| Hydraulic Station | Hydraulic station | Famous Chinese brand |

| Hydraulic Power | 5.5KW | |

| Runout Tables | Table type | Simple unpowered type |

| Function | To support the finished panels | |