The main features of the horizontal wave roof sheet machine efficient production speed and the advantage of adapting to thin materials.

The design philosophy of this machine emphasizes speed, with a production speed of approximately 20 to 60 pieces per minute, making it particularly suitable for processing thin materials, such as those with a thickness of 0.12 to 0.3 millimeters. In addition, when processing thin materials, the transverse arc machine can effectively avoid the problem of rebound at both ends of the product due to the multiple processing steps of the gear shaft.

Applicable materials and application scenarios

The horizontal wave roof sheet machine is suitable for processing thin materials, such as color steel tiles with a thickness of 0.12-0.3 millimeters. This type of machine is particularly popular in the African market because thin materials have a wide range of application demands locally.

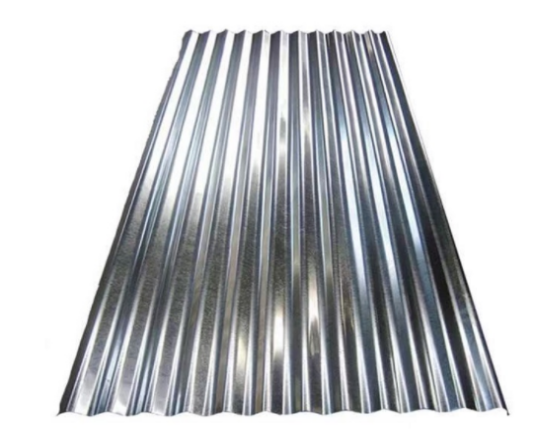

Finished product photos of the horizontal wave roof sheet machine:

Profile Drawing of the horizontal wave roof sheet machine:

The technical specifications of the horizontal wave roof sheet machine:

| Item | Name | Specifications |

| 1 | Raw material | PPGI,PPGL |

| 2 | Raw material thickness | 0.12-0.3 mm |

| 3 | Material of rollers | High grade 45# forged steel |

| 4 | Forming stations | 2 sets (4 pieces) |

| 5 | Roller diameter | 450mm |

| 6 | Forming speed | 2-3 seconds per piece |

| 7 | voltage | 380V/50HZ/3P (as requested) |

| 8 | Main motor | 7.5 KW |

Common problem:

Because the raw material is relatively thin, the two ends of the product areprone to rebound, but our machine gear shaft has more processing procedures than others, sothis problem can be effectively avoided.

Horizontal wave roof sheet machine is widely used in multiple industries, including:

1.Aerospace: Used for processing various workpieces that require high-precision circular arc shapes.

2.Automotive manufacturing: In the production of automotive components, arc machines can provide precise arc machining.

3.Mechanical manufacturing: used for producing various large or small workpieces to meet high-precision machining requirements.

4.Home decoration: The use of circular arc machines can improve the quality and aesthetics of consumer goods such as furniture and lighting fixtures.

Details of the horizontal wave roof sheet machine:

Packing Style:

Packing method :Main body of machine is naked and covered by plastic film(to protect of dust and corrosion),oaded into container and steadily fixed in container suitable by steel rope and lock, suitable for long-distance transportation.