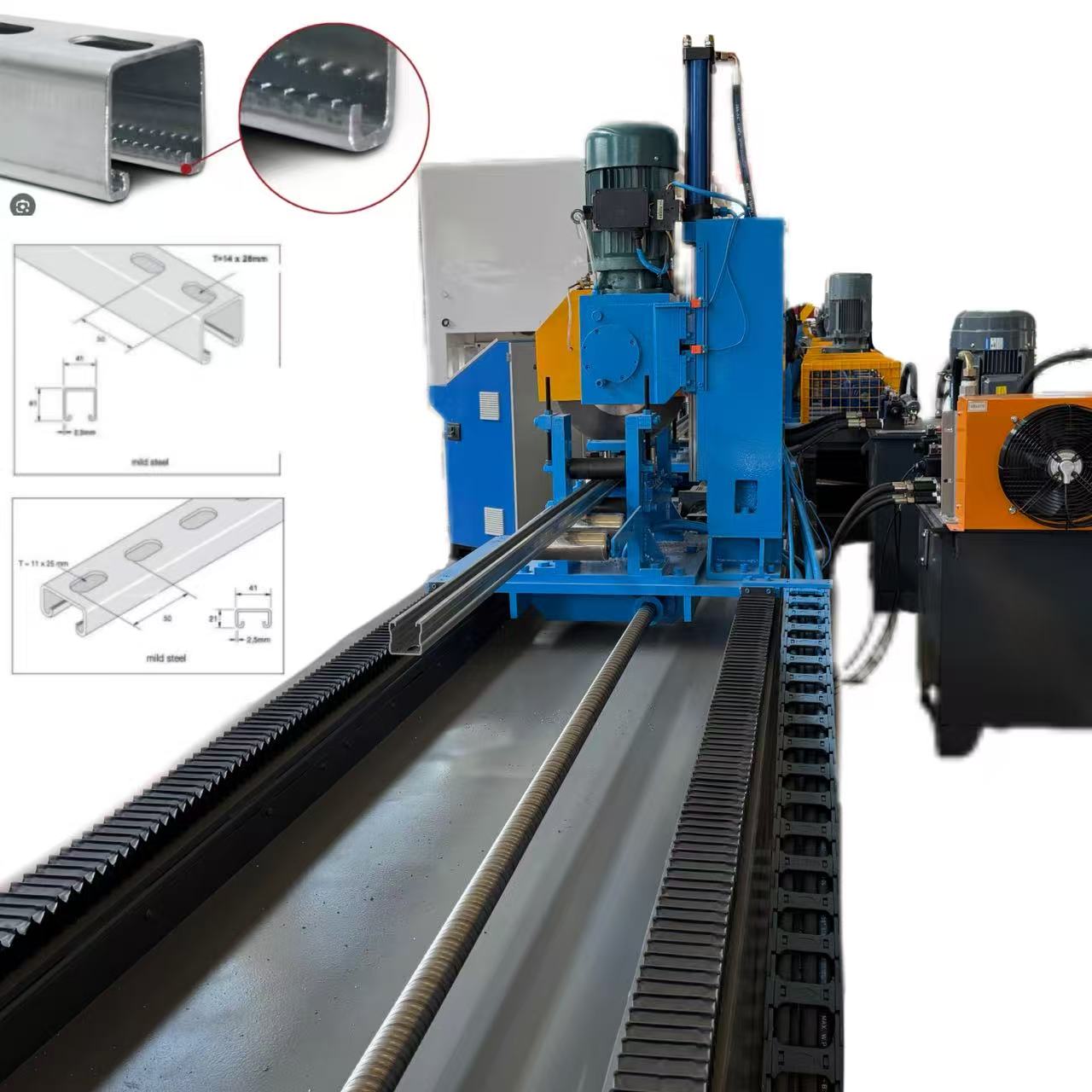

The Highway Guardrail Roll Forming Machine is an advanced industrial device designed for the efficient production of highway guardrails. With precision and speed, this machine effortlessly shapes metal strips into precise and high-quality guardrail profiles used for road safety. It offers versatility in creating different sizes and designs of guardrails, meeting diverse industry requirements. The machine’s automated operations and customizable settings ensure consistent results, reducing labor costs and improving productivity. The Highway Guardrail Roll Forming Machine is an essential tool for manufacturers aiming to optimize production and deliver reliable and durable guardrails, contributing to safer road infrastructure and enhanced traffic safety.

Highway Guard Rail Two Wave or W beam Cold Roll Forming Machine is designed to make the W beam or two wave guardrail in batch fully automatically. Highway collision avoidance facilities, isolation and other facilities. Mainly used for traffic security projects such as highways, primary and secondary roads, provincial roads, county roads and rural road scenic spots, large parking lots, etc.

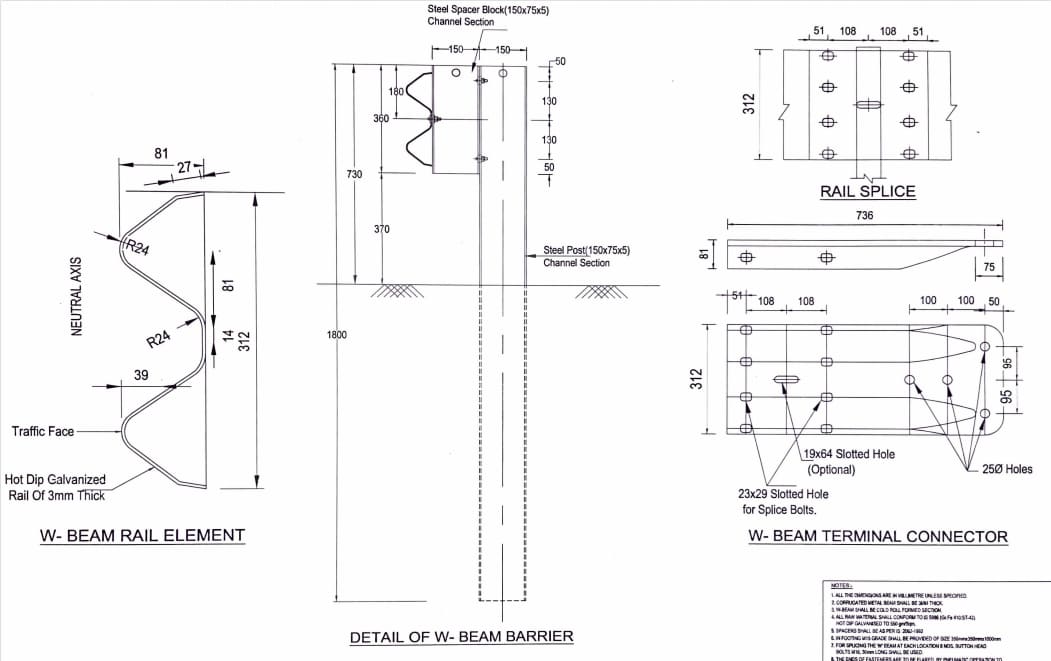

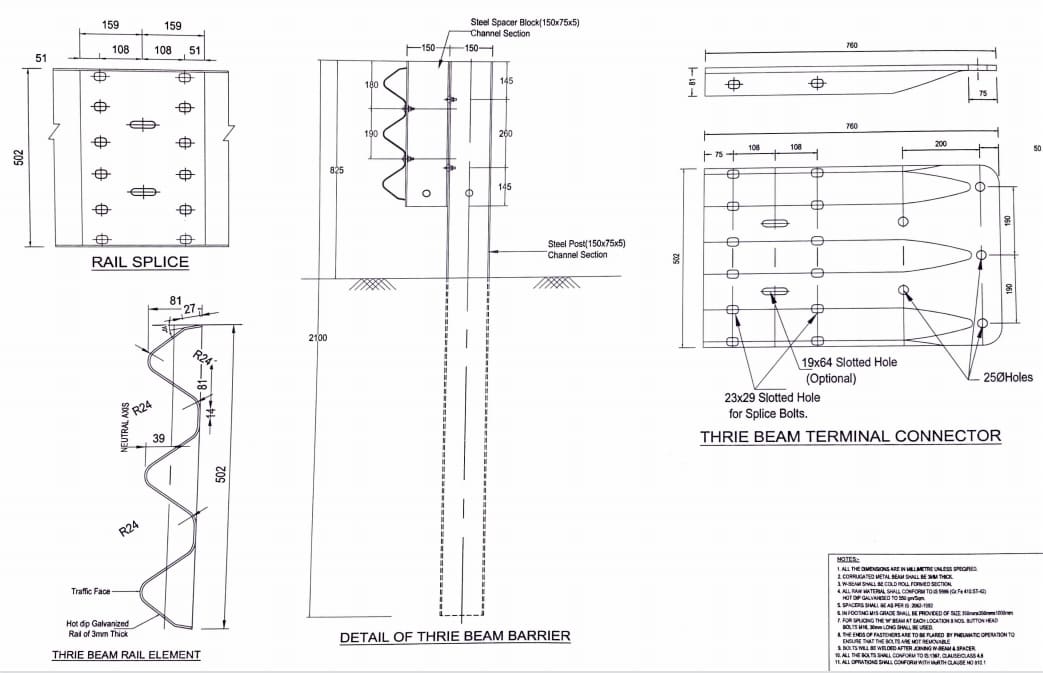

Here are some highway guardrail drawing profiles for your reference:

Highway Guard Rail Two Wave or W beam Cold Roll Forming Machine:

For the guardrail machine design, we have the following types for your reference:

- Two wave guardrail roll forming machine.

- Three wave guardrail roll forming machine.

- Two and three wave guardrail roll form machine.

As to the machine design whole working flow, it could be designed as before shearing and after shearing.

The difference of before shearing and after shearing lies in that:

Before shearing will be a little faster than the after shearing.

If two types supported, no need to change the cutting blade.

But before shearing end and start will be a little sizes error.

- For the transmission part, we can use the gearbox type or the middle plate chain transmission

- Working flow of guardrail roll forming machine :

Uncoiling → Alignment guiding roller → 9 rollers leveling → hydraulic punching hole → Panel Transport table → Swift sheet feeding → Photoelectrical switch→ Roller guiding table → 15 stations roll forming → Finished product support table.

Features for Highway Guard Rail Two Wave or W beam Cold Roll Forming Machine

- As to the decoiler, you can choose manual one or the hydraulic one.

- For the roller material, we use G2 or SKD11 material for long time to use.

- For the frame, we use the molding frame.

- For the punching, we use before punching and PLC control.

- For the based frame, solid steel and steady and long time to use.

- Before shearing and after shearing both optional.

Highway Guard Rail Two Wave or W beam Cold Rolled Forming Machine working videos for your reference: