The features of this trapezoidal roof tile making machine:

1.Fast speed-25m/min forming speed ,very fast ,more efficiency.

2.One machine can use both 1220/1000mm width coil.

3.The voltage of this machine is 380V/50HZ.

4.Stable forming-the roller stand is vertical cast steel stand ,gearbox driving,very strong ,the forming very stable and final product very accurate.

5.Roofing sheet has many different shapes,we can customize the machine as customers’ demand.

The pictures for the finished product:

The profile drawing for the felt sheet:

The components of the trapezoidal roof making machine:

| No. | Name | Quantity |

| 1 | Manual/hydraulic Decoiler | 1 set |

| 2 | Felt device | 1 set |

| 3 | Main roll former | 1 set |

| 4 | Control system | 1 set |

| 5 | Hydraulic system | 1 set |

| 6 | Product Run-out table | 1 set |

The technical specifications of the trapezoidal roof making machine:

| Item | Name | Specifications |

| 1 | Raw material | PPGI,PPGL |

| 2 | Raw material thickness | 24/26 gauge (0.4-0.6 mm) |

| 3 | Decoiler | 5T Hydraulic decolier |

| 4 | Felt device | Available |

| 5 | Roller station | 16 rows |

| 6 | Roller material | High grade 45#,with heat treatment |

| 7 | Shaft diameter | Φ80mm solid |

| 8 | Shaft material | High grade 45#,with heat treatment |

| 9 | Transmission | By pillar type Cylinder |

| 10 | Motor power | 11 KW |

| 11 | Machine frame | 350mm H beam structure |

| 12 | Cutting type | Hydraulic post cutting |

| 13 | Hydraulic power | 11 KW |

| 14 | Cutting blade material | Gcr12 quenched treatment |

| 15 | Cutting tolerance | +/-1mm |

| 16 | Control system | PLC |

| 17 | Brand | PLC:Delta(Taiwan) PLC, and transducer and touched screen Encoder:Omron Electrical components:Schneider |

The features of our trapezoidal roof making machine:

1.Decoiler:It is equipped with the cantilever.Motor drive the coils running and can do forward and reverse running as well as do the decoiling with tension.

2.Roll forming machine:

- Machine frame:350# H steel welded

- Transmission:By pillar type Cylinder

- Shaft diameter:80mm solid,all the shaft are guaranteed solid

- Roller material:High grade 45#,with heat treatment

3.Cutter:We use four pillars cutting system structure, it can make sure the cutting stable.

4.Control system:PLC brand:Delta(Taiwan) PLC, and transducer and touched screen,Encoder brand:Omron,Electrical components:Schneider.

5.Hydraulic system:Main components:Include a set of hydraulic tank, a set of hydraulic oil pump, two hydraulic pipes. And one of electromagnetism valve.

6.Automatic stacker

Function :Collect the finished product automatically ,save labor,and very efficiency.

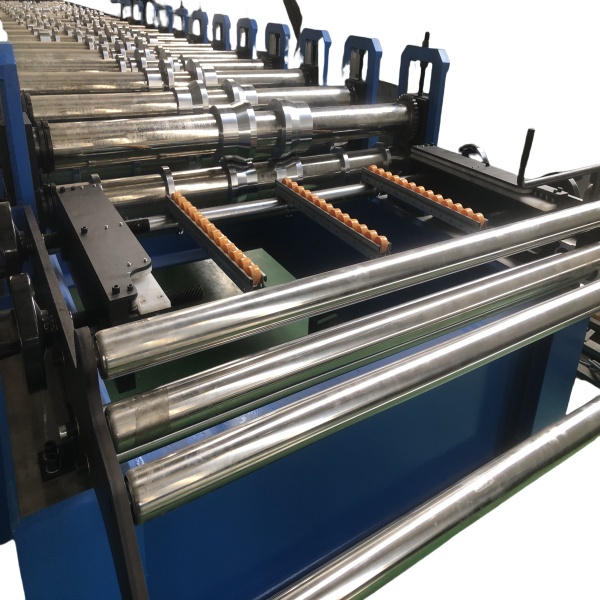

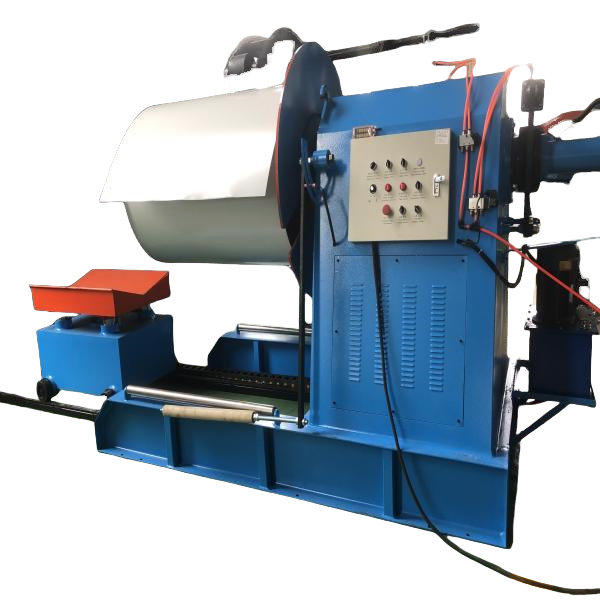

The pictures of our ibr roof sheeting roll forming machine:

1.Manual decoiler

2.Felt device

3.Roll former

4.Control station & hydraulic station