Recommend related video:

Metal glazed roll tiles are usually made from materials like steel or aluminum, which are renowned for their high strength, long lifespan, and corrosion resistance. These metal sheets go through precise manufacturing procedures to create individual tiles with specific profiles and shapes. Subsequently, these tiles are covered with a specialized glaze using advanced techniques to form a protective layer on the metal surface.Cangzhou ZTRFM specializes in the design and construction of customized roll – forming machines more than ten years.

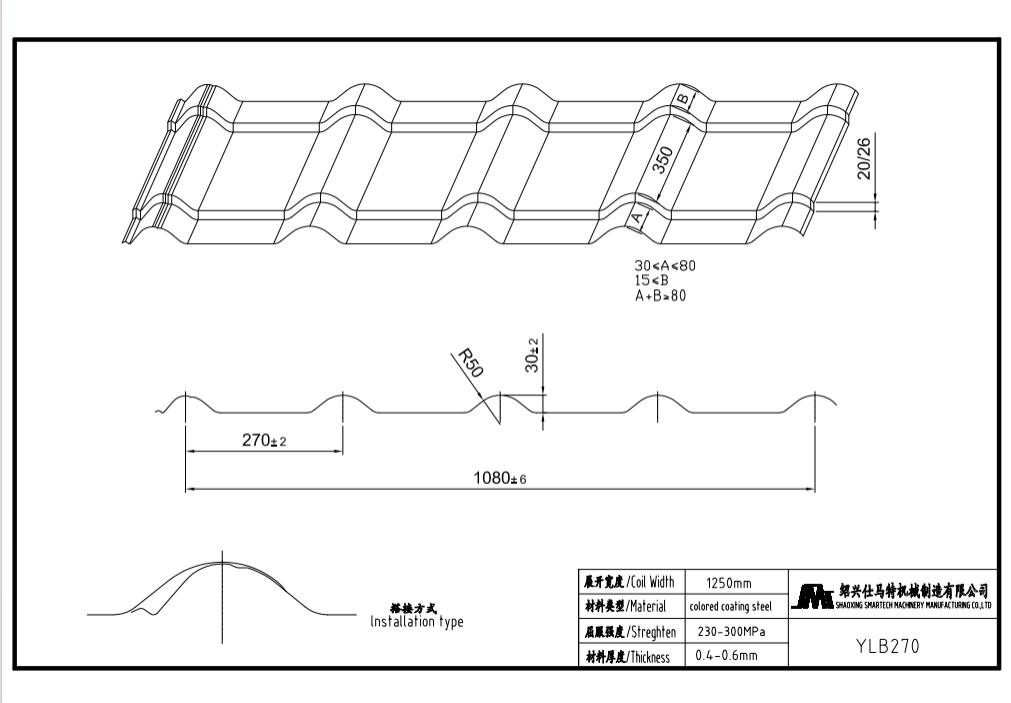

The drawing profile:

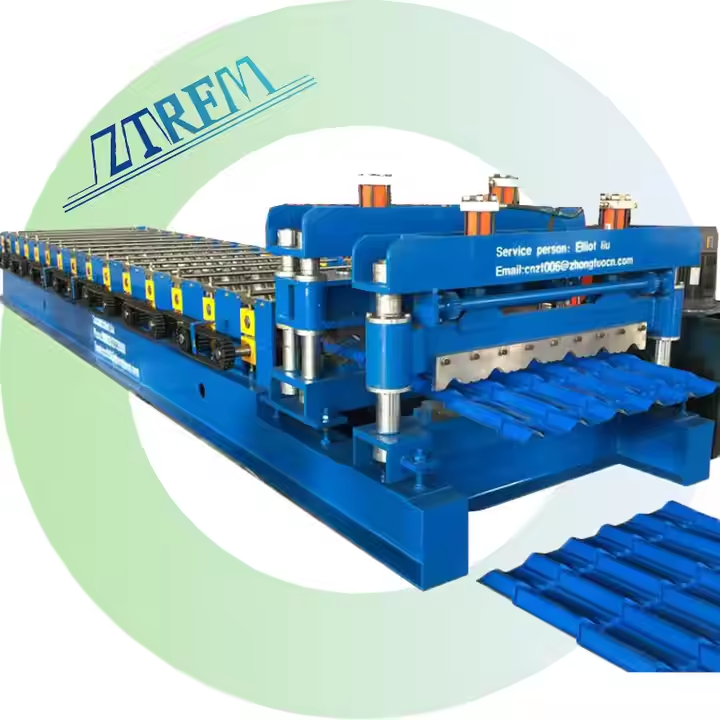

Finished product pictures:

Here are some machine parameter for your reference:

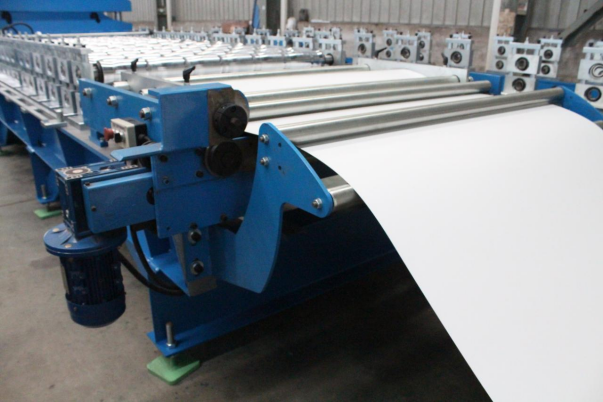

1.Pre-cutting Device:

For pre-cutting the sheet

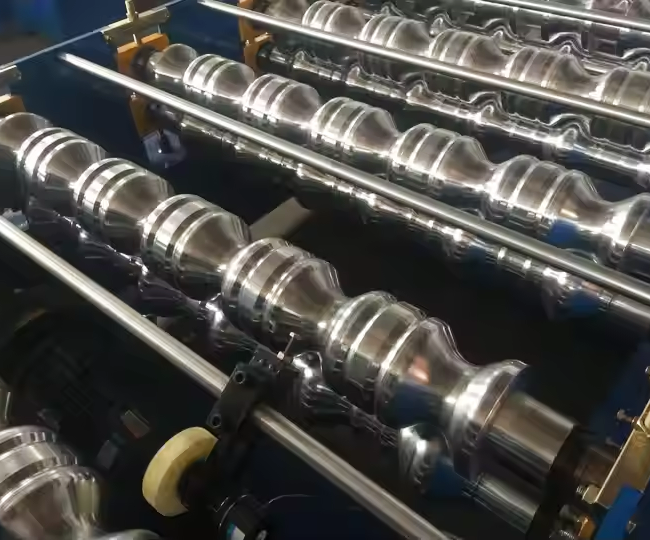

2.Roll Forming System:

| Machine frame | welding structure with blasting treatment |

| Roller meterial | high quality no.45 steel with hard chrome-painted |

| Diameter of shafts | Φ75mm |

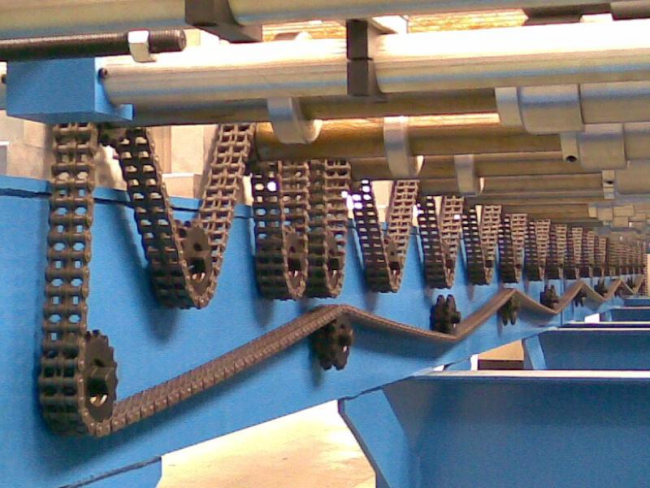

| transmission | chain transmission |

3.Punching die and Cutting Device:

1)The cutting blade material is Cr12 with quenched treatment, there is no material wasted.

2) The power of cutting is provided by Hydraulic station.

3) There’re two punching depth of the tile profile,

20mm and 26mm, while changing the gaskets, it is require that lower die can be easily replaced by the cylinder lifting.

Recommend related machine: