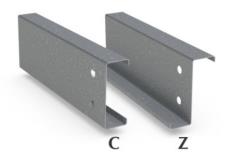

Purlins are steel elements which are used as support structures in pre engineered buildings, mainly below the roofs. Purlins provide extra roof support, creating a horizontal diaphragm that provides support to the weight of the roof and deck. Purlins are installed parallel to the building eave and are supported by rafters or walls. The raw material used to fabricate purlins are cold formed steel. It can span a length of upto 30 feet or longer.

The length and width depends on the dimensions of the primary frame of the building, its usage and engineering design. Added stiffness can be given to purlins to prevent loss of structural strength, as required. Purlins are therefore an important part of the roof structure. In pre engineered buildings, steel purlins are widely used. They are lightweight, durable structures that are built to precision, having consistency in dimensions. Purlins expand and contract in summer and winter respectively.

This C purlin roll forming machine adopts new components with high quality material. The hydraulic system and electrical control system are all use advanced and reliable world famous brand. Designed by the advanced ZTFRM program, the machine has easy and reliable operation. Rollers are most important parts of the machine, that we make find machining for all rollers, with high quality material, to make sure the machine can be worked stably for long time.

1.How to count then input coil width of the C and Z purline?

Calculate the input coil width according to the finished product size: waist height*2 + bottom width + small edge – material thickness * 6, for example, if finished C profile size as follows Waist height: 50mm, bottom width: 100mm, small edge:15mm, material thickness:2mm

Then input coil width is 50*2+100+15*2-2*6=218mm

2.How to do the wiring?

The hydraulic uncoiler only needs to connect the power cord to the four terminals marked A,B,C and N.

The main roll forming machine needs to be connected with the power cord, the main motor, the oil pump motor and the size adjustment motor.

Power cord: connect with terminals marked with L1, L2, L3

Main motor: connect with terminals marked with U2, V2, W2

Oil pump motor: connect with terminals marked with U1, V1, W1

Size adjustment motor: the three size adjustment motors are connected to the terminal marked with U3 V3 W3, U4 V4 W4 and U5V5W5 respectively.

The counter, limit switches of punching units and cutting devices are connected to the PLC control cabinet with aviation plugs, which are unique, easy to connect and free of errors.

If you are Interested this machine please contact me:

Whatsapp: 0086 18631755623

Email: cnzt011@zhongtuocn.com