Glazed sheets are widely used in the decoration of buildings, especially in the restoration of ancient architecture, garden landscapes, and high-end residences, due to their bright colors and brilliant luster. The application of glazed sheets can enhance the aesthetic value of buildings.

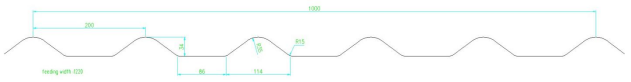

The pictures for the finished product:

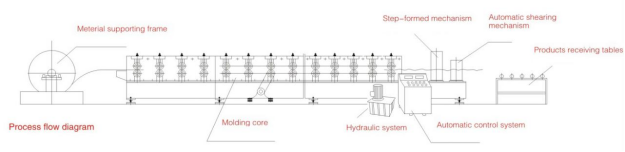

Production process:

Uncoiler-Feeding material into machine→Roll forming→hydraulic cutting→ Products receiving

Packing list of the Glazed tile roofing sheet machine :

| No. | Name | Quantity |

| 1 | Manual/hydraulic Decoiler | 1 set |

| 2 | Main roll former | 1 set |

| 3 | Control system | 1 set |

| 4 | Hydraulic system | 1 set |

| 5 | Product Run-out table | 1 set |

The technical specifications of the Glazed tile roofing sheet machine :

| Item | Name | Specifications |

| 1 | Raw material | colored steel plate, galvanized plate, or aluminum plate |

| 2 | Raw material thickness | 0.3—0.8mm |

| 3 | Decoiler | 5T |

| 4 | Felt device | Available |

| 5 | Roller station | 14stations |

| 6 | Roller material | 45# steel, surface hard chromium plating. |

| 7 | Shaft diameter | 80mm |

| 8 | Shaft material | 45# steel |

| 9 | Transmission | By double chains |

| 10 | Motor power | 5.5kw |

| 11 | Machine frame | 350 H steel |

| 12 | Cutting type | Hydraulic cutting |

| 13 | Hydraulic power | 5.5kw |

| 14 | Cutting blade material | Cr12 quenched |

| 15 | Cutting tolerance | +/1mm |

| 16 | Control system | Delta/ Siemens PLC |

The function of the Glazed tile roofing sheet machine :

1.Market demand growth:

With the gradual stabilization of the South American economy and the acceleration of urbanization, the demand for high-quality building materials is becoming increasingly prominent. As a key equipment for producing glazed tiles, glazed tile roofing sheet machinecan meet the growing demand in this market.

2.Environmental protection and energy conservation:

The demand for environmental protection and energy conservation in the South American market is increasing day by day. During the design phase of the glazed tile roofing sheet machine, the need to reduce waste emissions and save energy was taken into consideration. By using recyclable materials and optimizing production processes, the impact on the environment was reduced and resource utilization efficiency was improved.

3.Policy support:

In recent years, governments of South American countries have increased their investment in infrastructure, especially in sustainable development projects, providing new market opportunities for glazed tile roofing sheet machine.

4.Weather resistance:

The climate in South America is diverse, and the glazed sheets produced by glazed tile roofing sheet machinecan adapt to different climate conditions due to their excellent weather resistance, protecting buildings from natural disasters.

5.Economic impact:

The production and sales of glazed tile roofing sheet machinecan create employment opportunities and have a positive impact on the local economy, especially in the construction industry.

6.Market competition:

The South American market is fiercely competitive, and the advancement of production technology and product upgrades for glazed tile roofing sheet machine helps companies maintain competitiveness in the market.

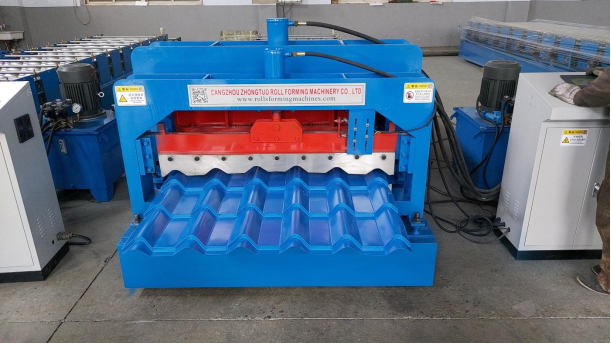

Some details of the Glazed tile roofing sheet machine :