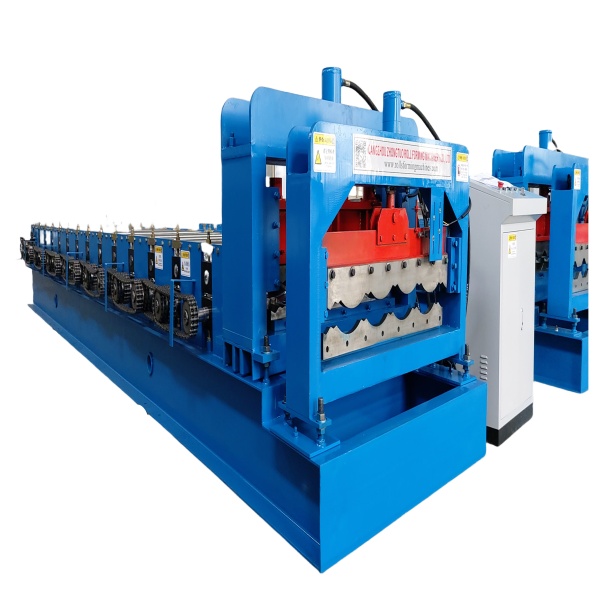

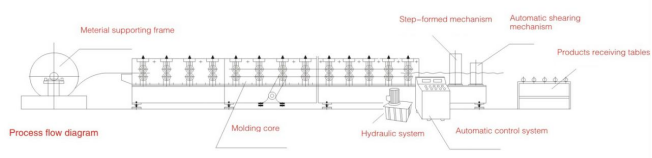

Glazed tile roofing sheet machines are used to produce glazed tile roofing sheets, which are commonly used in construction for their durability and aesthetic appeal. These machines are designed to roll and form the sheets

from raw materials such as steel coils.It can be used as the roof for different kinds of buildings like villas, luxury houses, theaters, and exhibition centers.

Glazed tile roofing sheet machineis produced for Mexico customer,the features of this machine:

Production Capacity: The production capacity of glazed tile roofing sheet machines can vary, with some machines capable of producing up to 15 meters per minute.

Material Thickness:

The machines can process materials with thicknesses ranging from 0.3 to 0.6millimeters.

Feeding Width:

The feeding width of these machines typically ranges from 1000 to 1250 millimeters.

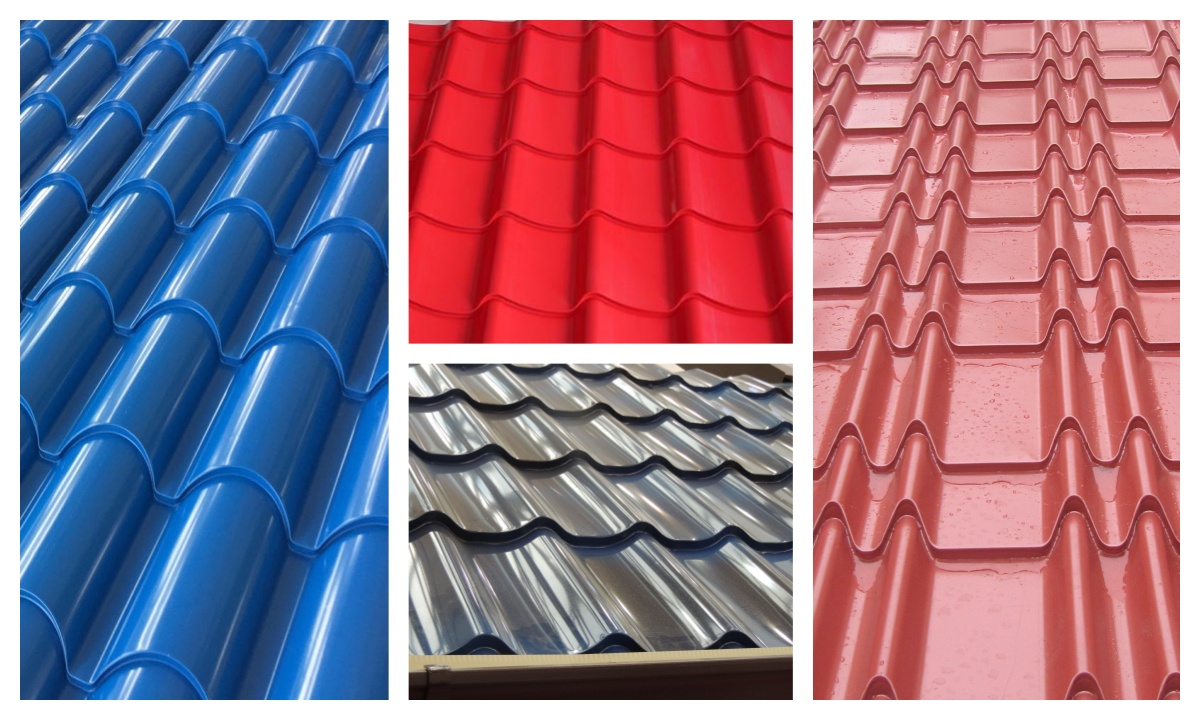

Application pictures of the Glazed tile roofing sheet machine:

Finished product photos of the Glazed tile roofing sheet machine:

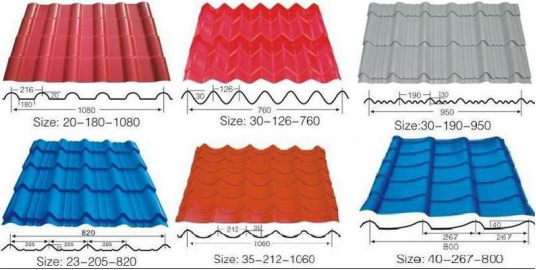

Profile Drawing Of the Glazed tile roofing sheet machine:

The technical specifications of the Glazed tile roofing sheet machine:

| Item | Name | Specifications |

| 1 | Raw material | PPGI (RAL8016) |

| 2 | Raw material thickness | 0.3-0.6 mm |

| 3 | Decoiler | 5T |

| 4 | Felt device | Available |

| 5 | Roller material | 45# STEEL |

| 6 | Shaft diameter | 75mm |

| 7 | Shaft material | 45# STEEL |

| 8 | Transmission | By Chains |

| 9 | Motor power | 5.5kw |

| 10 | Machine frame | 400# H steel welded |

| 11 | Cutting type | Automatic cutting after forming, no distorting or wasting. |

| 12 | Hydraulic power | 5.5 kw |

| 13 | Cutting blade material | GB-Cr12 |

| 14 | Cutting tolerance | ±0.5mm |

| 15 | Control system | PLC |

The function of the Glazed tile roofing sheet machine:

1.Good waterproof performance: It can effectively prevent rainwater from seeping into the interior of buildings, protecting the wooden structures of ancient buildings from erosion.

2.High strength: Suitable for various structures such as concrete structures, steel structures, wooden structures, brick wood hybrid structures, etc.

3.Rich colors: Customization can be made according to the architectural style and customer needs to enhance the aesthetics of the building.

4.Strong weather resistance: The service life is not less than fifty years, with excellent weather resistance and fire resistance.

5.Easy construction: The fastest paving speed, low construction cost, suitable for new sloping roofs and old building flat to sloping roofs.

In addition, the antique glazed tile equipment also pays attention to environmental protection and energy conservation, using high-quality raw materials and advanced production processes to reduce the impact on the environment, which is in line with the development concept of national green buildings.

Details of the Glazed tile roofing sheet machine:

Packing Style

Packing method :Main body of machine is naked and covered by plastic film(to protect of dust and corrosion),oaded into container and steadily fixed in container suitable by steel rope and lock, suitable for long-distance transportation.