Gearboxes can achieve acceleration or deceleration conversion by adjusting the size and meshing relationship of gears. For glazed tile roofing sheet machines, this means that the operating speed of the machine can be adjusted according to production needs to improve production efficiency or adapt to different working conditions.

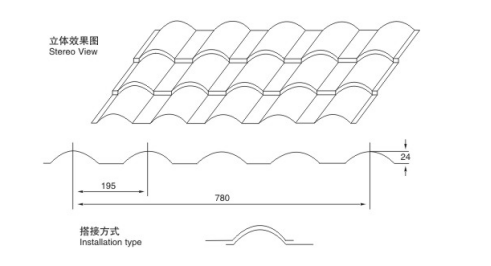

The profile drawing:

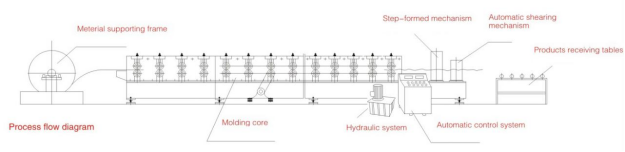

Production process:

Uncoiler-Feeding material into machine→Roll forming→hydraulic cutting→ Products receiving

Packing list of the Glazed tile roofing sheet machine for gearbox transmission:

| No. | Name | Quantity |

| 1 | Manual/hydraulic Decoiler | 1 set |

| 2 | Main roll former | 1 set |

| 3 | Control system | 1 set |

| 4 | Hydraulic system | 1 set |

| 5 | Product Run-out table | 1 set |

The technical specifications of the Glazed tile roofing sheet machine for gearbox transmission:

| Item | Name | Specifications |

| 1 | Raw material | colored steel plate, galvanized plate, or aluminum plate |

| 2 | Raw material thickness | 0.3—0.8mm |

| 3 | Decoiler | 5T |

| 4 | Felt device | Available |

| 5 | Roller station | 20stations |

| 6 | Roller material | 45# steel, surface hard chromium plating. |

| 7 | Shaft diameter | 80mm |

| 8 | Shaft material | 45# steel |

| 9 | Transmission | By Gearbox |

| 10 | Motor power | 5.5kw |

| 11 | Machine frame | 350H steel |

| 12 | Cutting type | Hydraulic cutting |

| 13 | Hydraulic power | 5.5kw |

| 14 | Cutting blade material | Cr12 quenched |

| 15 | Cutting tolerance | +/1mm |

| 16 | Control system | Delta/ Siemens PLC |

The function of the Glazed tile roofing sheet machine for gearbox transmission:

1.Change the transmission direction:

Gearboxes can use structures such as sector gears to change the direction of force transmission, which is crucial for the transmission and distribution of force in glazed tile roofing sheet machines.

2.Change the rotational torque:

Gearboxes can change the rotational torque. Under the same power conditions, the faster the gear rotates, the smaller the torque on the shaft, and vice versa. This is very important for the torque control required by the glazed tile roofing sheet machine during the pressing process.

3.Clutch function:

Gearboxes can separate the engine from the load by separating two originally meshing gears, such as in glass tile machines for starting, stopping, or shifting operations.

4.Improve efficiency and reliability:

Through performance optimization techniques such as gear design optimization, lubrication system improvement, structural lightweight design, and vibration and noise control, gearboxes can significantly improve the efficiency and service life of glazed tile roofing sheet machines.

5.Lubrication system:

The lubrication system of the gearbox is of great significance for the normal operation of the machine. Large glazed tile roofing sheet machines must be equipped with a reliable forced lubrication system to spray oil lubrication on the gear meshing area, bearings, etc., to ensure the normal operation of the gearbox and extend its service life.

Some details of the Glazed tile roofing sheet machine for gearbox transmission: