Related video

The glazed colored roof sheet roll forming machine is capable of producing glazed sheets in a variety of shapes, and there are numerous thicknesses and colors to choose from. Compared with traditional ceramic tiles, it has become quite popular. This is primarily because it has several advantages. To start with, it is cost-effective, allowing for substantial savings in economic costs. Secondly, it is lightweight, which makes it simpler to handle and install. Thirdly, it can greatly reduce the construction period, helping construction projects to be finished more rapidly. In addition, it is recyclable, being environmentally friendly. And its attractive appearance also enhances its charm. It can be used as the roof for different kinds of buildings like villas, luxury houses, theaters, and exhibition centers.

Customer drawing profile:

Working flow:

Here are some machine parameter for your reference:

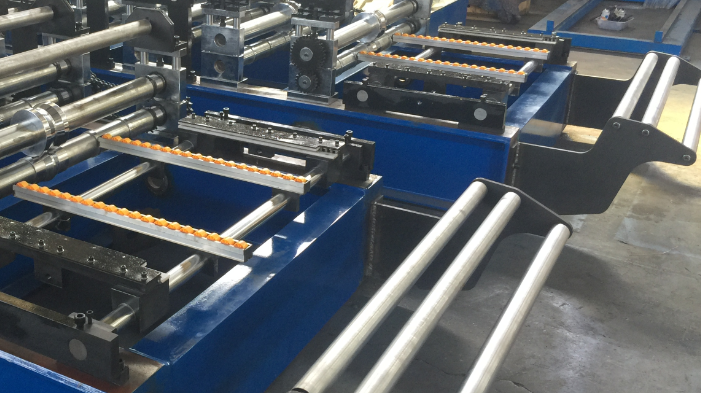

1.Entry Beach

This leveling part can protect the surface of the coil with rubber rollers.

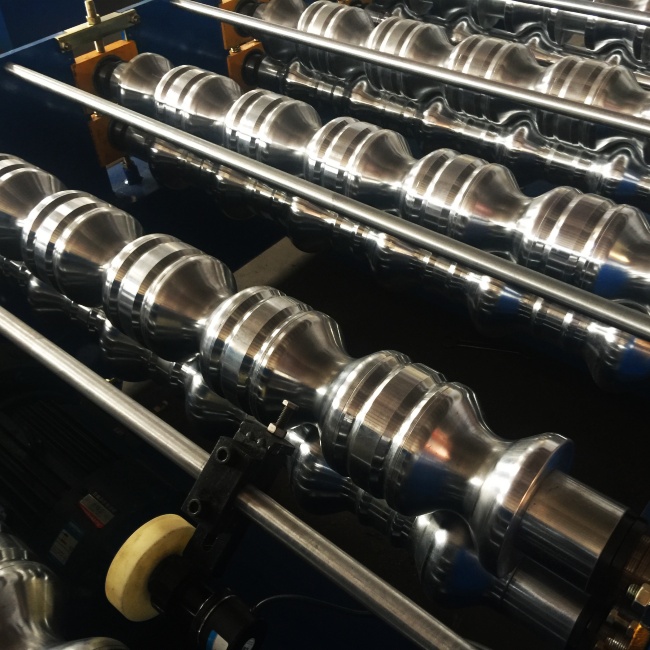

- Roll forming machine:

| Weight | 8 tons |

| Voltage | 380V/60HZ 3Phase or customize |

| Roller fixer | Mold frame of thickness 45mm |

| Frame | 500 H steel |

| Transmission | Gearbox |

| Material of rollers | 45# steel, surface hard chromium plating |

| Material of shafts | 45# steel |

| Diameter of shafts | Φ75mm |

| Number of rollers | 14 rollers |

| Main power | 7.5kw servo motor |

| Rolling speed | 25 m |

3.Shearing system

| Material of blades | Cr12 quenched |

| Power supply | hydraulic power |

| Components | It contains one set of blade, one hydraulic tank and one cutter machine |

4.Hydraulic Station

Recommend related machine