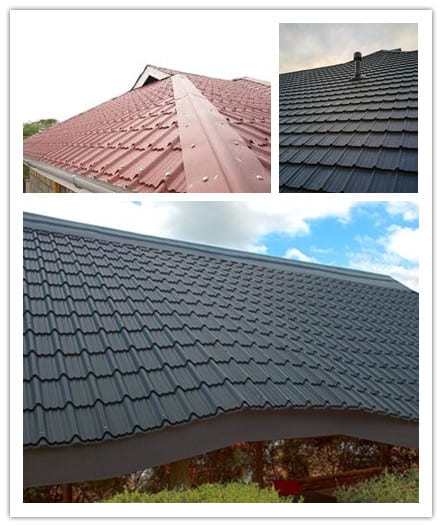

Aluminium and Aluzinc Versatile Roofing Sheets also known as Step Tile Roofing Sheets ,usually come in long spans. This type of roofing panel mimics the actual ceramic tile. Our state of the art step tile machinery is able to form them uniquely to your specifications.Versatile iron sheet roll forming machine is one most popular type of roll forming machines. It makes different shape of color steel roof sheet, which is used for buildings, factory, supermarket ect. For this machine, it suit coil width is 1000 mm, thickness range is from 0.23mm to 0.8mm. We adopt guide pin type to make machine frame strong. Usually it can run with the max speed to 3m/min, but this gearbox drive metal Versatile iron sheet roll forming machine speed can be up to 6-8m/min,very efficient.

DESCRIPTION

- Main Material used

Material: Color steel , galvanized steel, or Aluminum

Feeding width:1000mm

Material thickness:0.23-0.8mm

Yield strength:235-450mpa

- Machine composition

| NO. | NAME | UNIT | QUANTITY |

| 1 | 5T manual decoiler | set | 1 |

| 2 | Main roll forming machine | set | 1 |

| 3 | Hydraulic pressing part | set | 1 |

| 4 | Hydraulic cutting part | set | 1 |

| 5 | Product receiving table | set | 1 |

| 6 | PLC control station | set | 1 |

| 7 | Hydraulic oil station | set | 1 |

- Main parameters of Gearbox drive metal Versatile iron sheet roll forming machine

| 1 | Raw material | PPGI/PPGL/GI/GL |

| 2 | Raw material thickness | 0.23-0.8mm |

| 3 | Frame | Independent cast stand ,very strong |

| 4 | Roller material | 45# steel,hard chromed on the surface |

| 5 | Shaft material | 45# steel,heat treatment |

| 6 | Shaft diameter | 80mm |

| 7 | Main machine power | 11 KW |

| 8 | Voltage | 380V/50HZ/3P (as requested) |

| 9 | Pressing mould material | Cr12 steel,quenched |

| 10 | Cutting blade material | Cr12 steel,quenched |

| 11 | Cutting type | Hydraulic stop cutting |

| 12 | Transmission type | By gearbox |

| 13 | Hydraulic station power | 7.5KW |

| 14 | Production speed | 6-8m/min |

Our Advantages

Why we have more orders than other suppliers?

In this field,we have more orders because our machines have many advantages than machines from other suppliers.

1.Hand wheels on both sides can be used to adjust the feeding width.

2.Four stainless rollers can make the material go into the machine smoothly and prevent the scratch on the material surface.

3.There are three rows of orange plastic rollers can make the steel coil go into the machine smoothly.

4.Our PLC control station is stronger and more operator friendly, inside is very neat and there are some Aviation plugs for easier installation.

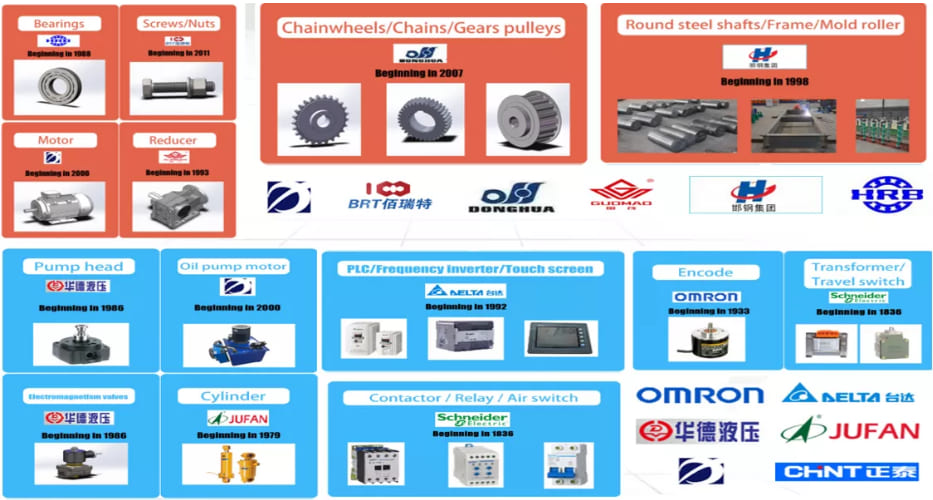

5.Our raw material and accessories source all use famous Chinese brand, which all have CE, ISO certificates,like bearing,screw/nuts, chain wheels, ect. though these are small parts for the machine,we will ensure the quality to avoid any problems.

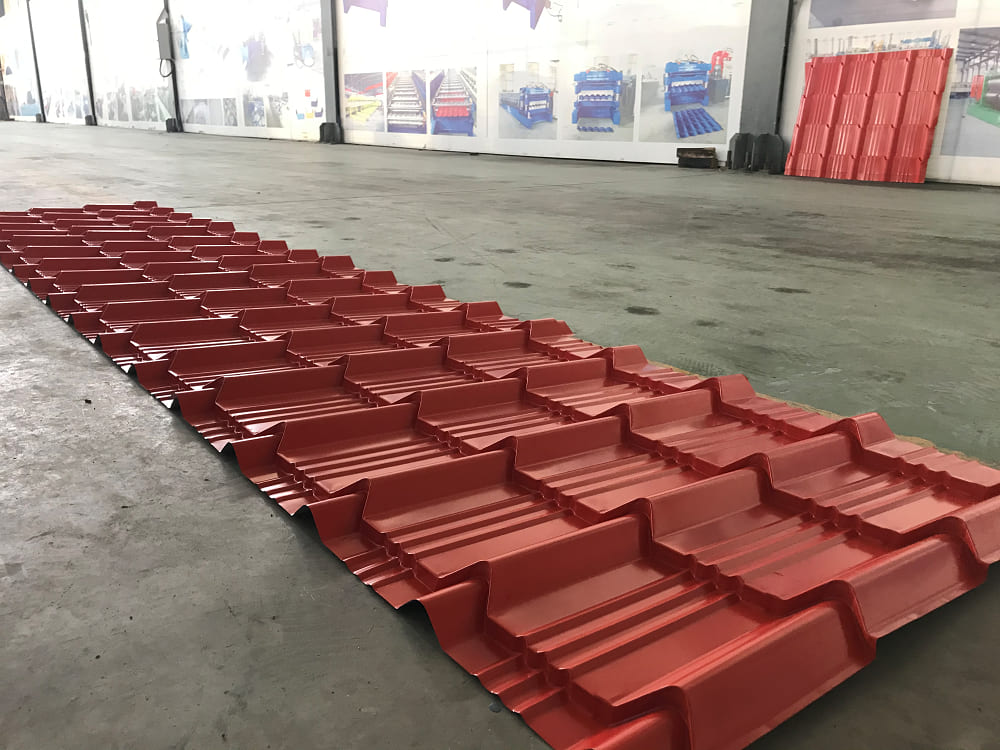

Main machine pictures

Final product picture

Product application