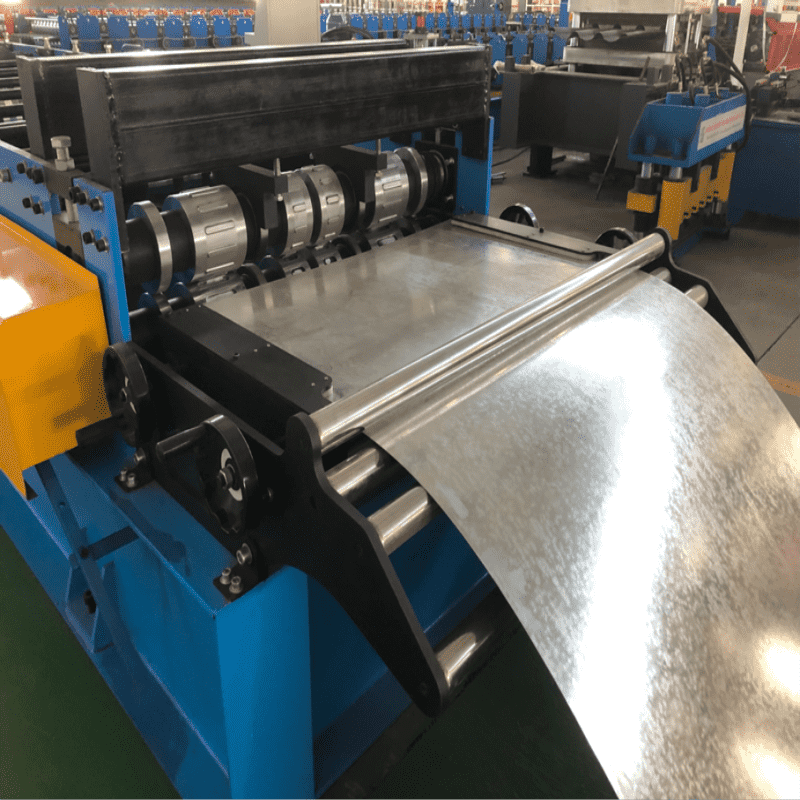

The Galvanized Metal Roof Decking Making Machine is an advanced industrial device designed to efficiently produce high-quality galvanized metal roof decking. With precision and speed, this cutting-edge machine effortlessly shapes galvanized metal sheets into precise and uniform roof decking profiles.The automated operations of the Galvanized Metal Roof Decking Making Machine ensure consistent and accurate results, optimizing production efficiency and reducing labor costs. It offers versatility in creating various sizes and designs of galvanized metal roof decking, catering to diverse construction needs and project specifications.This machine is an essential tool for manufacturers aiming to deliver reliable and durable galvanized metal roof decking for commercial, industrial, and residential buildings. With its state-of-the-art engineering and advanced control systems, it provides superior structural support and long-lasting performance.For the perfect galvanized metal roof decking production solution, look no further than the Galvanized Metal Roof Decking Making Machine. Explore the options available from leading manufacturers to meet your construction requirements.

What is galvanized metal floor decking machine?

Galvanized floor deck, suitable for steel structure construction, greatly improving the stiffness of the floor

1: To meet the requirements of rapid construction of the main steel structure, it can provide a firm working platform in a short time, and can use multiple floors to lay profiled steel plates and layer-by-layer pouring concrete slabs for flow construction.

2: In the use stage, the floor deck is used as the tensile reinforcement of the concrete floor, which also improves the stiffness of the floor and saves the amount of steel and concrete.

3: The embossing on the surface of the profiled plate makes the maximum bonding force between the floorboard and the concrete, so that the two form a whole, with stiffeners, so that the floorboard system has a high-strength bearing capacity.

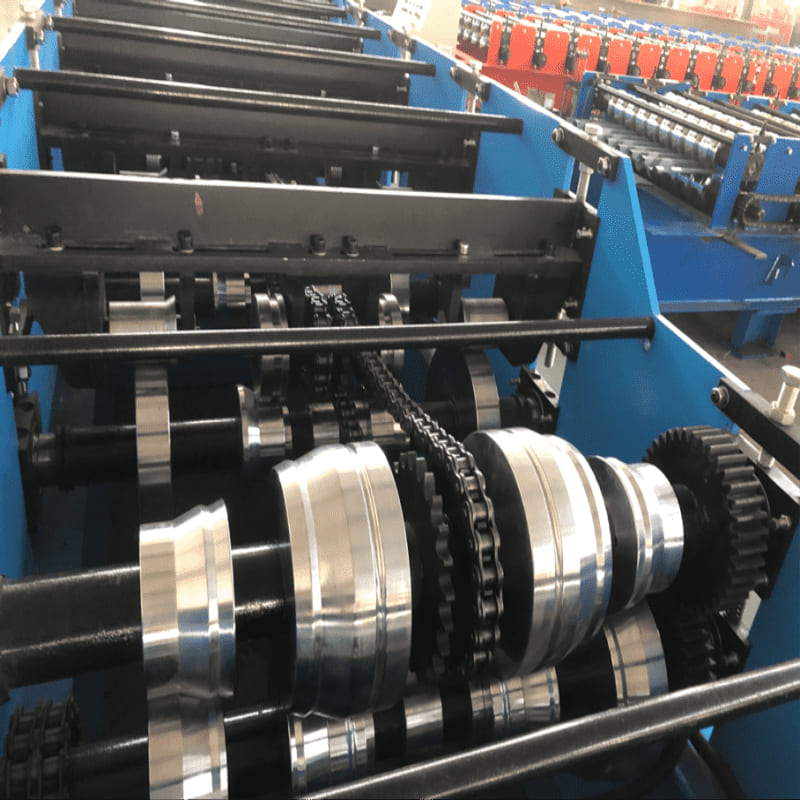

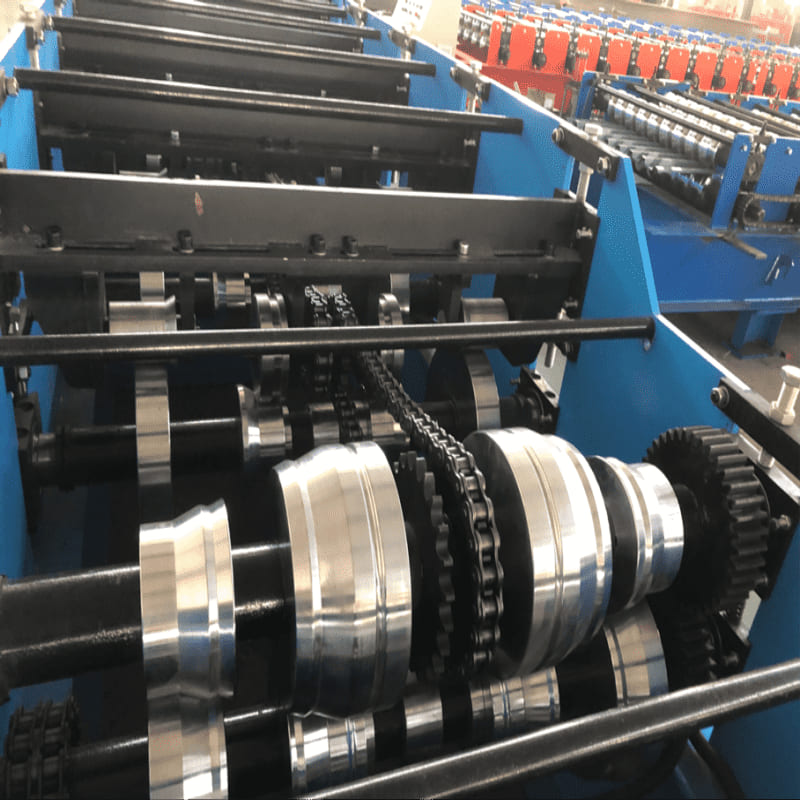

Advantages of ours:

1: Both the feeding port and the cut-off have added oiling devices to ensure the smoothness of the machine and avoid the falling of the zinc layer

2: Split molding mode, more molding volleyball, better molding effect

3.For high peaks, we will add chains to ensure the stable operation of the machine

There are more details of the machine in order to ensure that we are high-quality equipment. If you want to know more, you can send an inquiry and we support customization!