The floor decking forming machine plays an important role in the construction industry, mainly used for producing floor support plates. This equipment can significantly improve construction efficiency and reduce construction costs.

The pictures for the finished product:

Production process:

Uncoiler-Feeding material into machine→Roll forming→hydraulic cutting→ Products receiving.

Packing list of the Floor Decking Forming Machine:

| No. | Name | Quantity |

| 1 | Manual/hydraulic Decoiler | 1 set |

| 2 | Main roll former | 1 set |

| 3 | Control system | 1 set |

| 4 | Hydraulic system | 1 set |

| 5 | Product Run-out table | 1 set |

The technical specifications of the Floor Decking Forming Machine:

| Item | Name | Specifications |

| 1 | Raw material | GI&PPGI |

| 2 | Raw material thickness | 0.7-1.5mm |

| 3 | Decoiler | 5T |

| 4 | Felt device | Available |

| 5 | Roller station | 28stations |

| 6 | Roller material | 45# steel |

| 7 | Shaft diameter | 85mm |

| 8 | Shaft material | 45# steel |

| 9 | Transmission | By double chains |

| 10 | Motor power | 5.5kw |

| 11 | Machine frame | 400H steel |

| 12 | Cutting type | Hydraulic cutting |

| 13 | Hydraulic power | 5.5kw |

| 14 | Cutting blade material | Cr12 quenched |

| 15 | Cutting tolerance | +/1mm |

| 16 | Control system | Delta/ Siemens PLC |

The function of the Floor Decking Forming Machine:

1. Improve construction efficiency:

The floor decking forming machine can quickly and accurately complete the forming of the board through automated roll forming technology, greatly improving construction efficiency.

2.Reduce costs:

Floor slabs produced usingfloor decking forming machine have stronger load-bearing capacity and shear resistance, which can reduce the use of steel bars and concrete and thus lower construction costs.

4.Enhance structural strength:

The closed design makes the floor slab more sturdy and stable, meeting the building’s requirements for structural strength and load-bearing capacity.

5.Good fire resistance:

The floor slab system has excellent fire resistance and can provide additional safety protection in emergency situations such as fires.

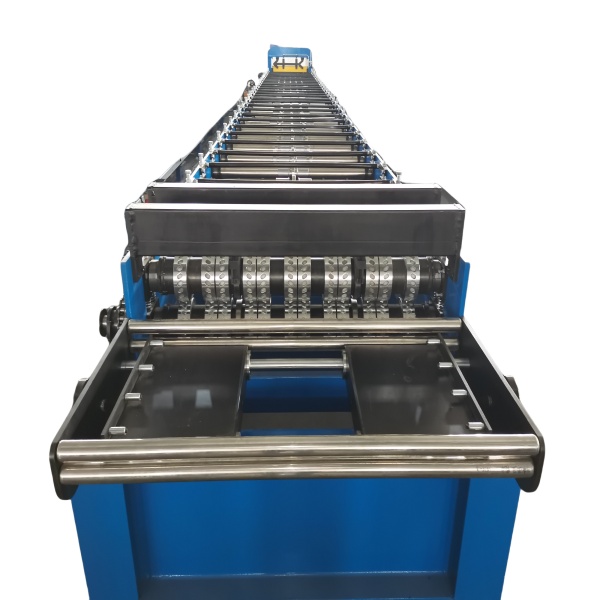

Machine photos:

Some details of the Floor Decking Forming Machine: