Product Description:

Floor deck making machinery is the special equipment for continuous rolling and cold-forming on steel sheet. It adopts coiling steel sheet as the raw material, decoiling the coil, continuous rolling and cold-forming, automatically cut to the size and output the finished panel. The equipment adopts PLC control, AC frequency and adjusting the speed technology, and it realizes the continuous automatically production, therefore, it is really a new type of energy-saving and high-effective producing equipment for steel structure.

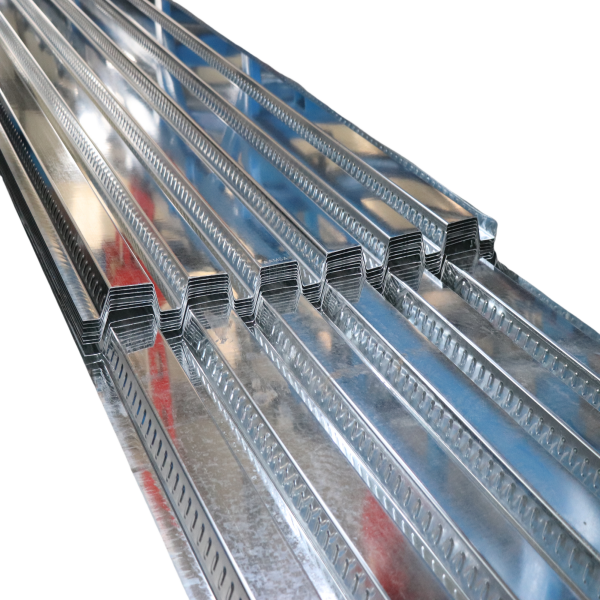

The profile drawing for the felt sheet:

Machine working flow:

Manual decoiler → Feeding material into machine →Roll forming machine →Measure length →Hydraulic cutting →Finished Products

The technical specifications of the floor Deck Roll Forming Machine:

| Item | Name | Specifications |

| 1 | Raw material | S350 & S450 grade steel |

| 2 | Raw material thickness | 0.3-1.2mm |

| 3 | Decoiler | 5T |

| 4 | Felt device | Available |

| 5 | Roller material | 45# steel, surface hard chromium plating |

| 6 | Shaft diameter | 90mm |

| 7 | Shaft material | 45# steel |

| 8 | Transmission | By chains |

| 9 | Motor power | 25kw |

| 10 | Machine frame | 400# H steel welded |

| 11 | Cutting type | Hydraulic |

| 12 | Hydraulic power | 4kw |

| 13 | Cutting blade material | Gcr12 |

| 14 | Cutting tolerance | ±1mm |

| 15 | Control system | PLC |

The main function of the Floor Deck Roll Forming Machine:

1.The bonding ability between the profiled steel plate of the floor slab and the concrete is very good.

2.Horizontal shear reinforcement can greatly improve the bonding effect between profiled steel plates and concrete, greatly enhancing the shear resistance of composite slabs, but the improvement in bending resistance is not significant.

3.The test shows that the ultimate bearing capacity of the board is greater than 3.12, and the bearing capacity under normal use is greater than 1.76, indicating a high bearing capacity.

4.The ultimate shear bearing capacity is greater than the theoretical calculation result, and the shear capacity meets the requirements.

5.This type of profiled steel plate meets the design requirements for bearing capacity, has good ductility, and has a large strength reserve, making it highly valuable for promotion and application.

6.The construction is simple and fast, and the splicing is convenient.

7.Replace traditional templates and improve their shortcomings.

8.It can be used as part of the structural strength to reduce material costs.

9.Easy to construct reinforcement, wiring, and piping.

10.Beautiful and practical, with an overall design.

Details of the floor Deck Roll Forming Machine:

Packing Style

Packing method :Main body of machine is naked and covered by plastic film(to protect of dust and corrosion),oaded into container and steadily fixed in container suitable by steel rope and lock, suitable for long-distance transportation.