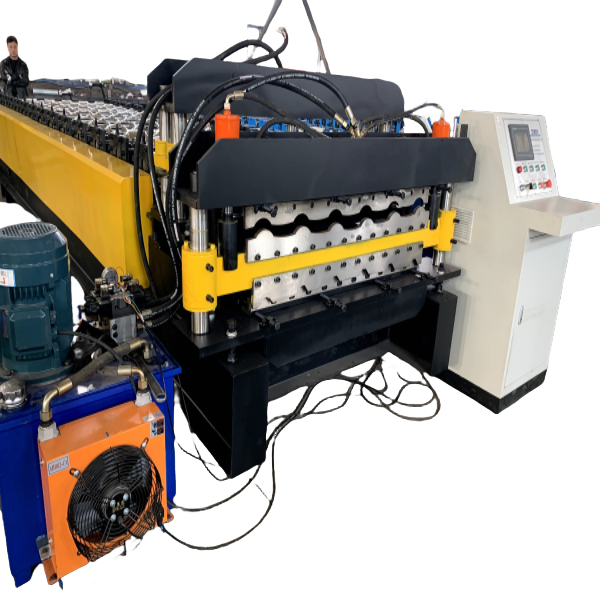

ZTRFM Introducing the Double Layer Roofing Roll Forming Machine – a cutting-edge solution for producing top-quality roofing panels. With dual-layer capabilities, it offers enhanced efficiency and versatility. Experience precision, speed, and seamless operation for your roofing needs. Elevate your roofing production now!

Does one roll forming machine can produce two types of roofing sheet?

—-Yes.

As we knows,one roll forming machine can produce one type of roofing sheet.But sometimes some customers want to produce different types,such as IBR/trapezoidal sheet,Corrugated sheet and tiles,but their budget is not enough and the workshop’s space is not enough.In this way,a double layer machine will be very useful.

Pictures of the Double Layer Roll Forming Machine:

Double layer roll forming machine is to produce two different types of roofing sheet,there are several designs for options:

- Double layer for two different sizes of trapezoidal sheet.

- Double layer for trapezoidal sheet and corrugated sheet.

- Double layer for trapezoidal sheet and tiles.

- Double layer for corrugated sheet and tiles.

- Other designs as per customer’s request.

Now I will introduce the Double layer roll forming machine for Trapezoidal sheet and corrugated sheet as the sample machine,this type is very popular.

The whole production line include:Decoiler,roll former,hydraulic cutting system,control system and receive table.

Part 1:Decoiler

- Function:To support the coil for production

- Types:Manual and automatic for option

- Capacity:Normal 5 tons,other weight also can customized

Manual decoiler’s picture

Hydraulic decoiler’s picture:

Part 2:Roll former

The roll former part include the machine frame,feeder,shaft and rollers,chain transmission,motor,cutter etc,it is used to produce the flat sheet to trapezoidal sheet or corrugated sheet.Up layer is to produce the corrugated sheet and the down layer is to produce the trapezoidal sheet.

(1).The feeders:our feeders use the stainless rollers to avoid the material from scratching.

(2).Shaft and Rollers:All of our shaft are solid,and our rollers are hard chromed to improve the hardness of the roller so that it can use longer time.

(3).Cutting device:Stronger guide post cutting device and the blade holder which will make the cutter working more stable and long life-time.

Part 3:Control system

Our machine adopt famous brand in the control system,such as Siemens PLC and touch screen,Schneider low voltage apparatus and omron encoder,these brand electric parts have after-sale service in the whole world which is more convenient for customer.

Part 4: Hydraulic system:

Our hydraulic system is equipped with the fan cooling system,it can cool down the oil during long time working or at hot weather.

We Cangzhou Zhongtuo Roll Forming Machinery Co.,Ltd has been in this industry for many years,and we also a lot of experience in the machines,we also support customization as our customer’s request,welcome to contact us if you need this kind of machines.