Our machine adopts an advanced double-layer design, which can process two layers of roof panels simultaneously, greatly improving production efficiency and material utilization. Its operation interface is intuitive, the control system is advanced, and operators only need simple training to get started, greatly reducing labor costs.

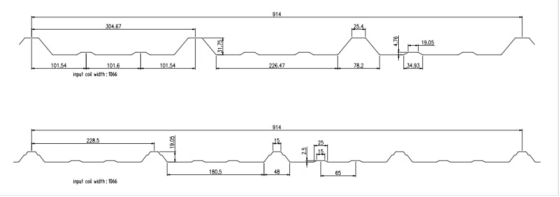

The pictures for the finished product:

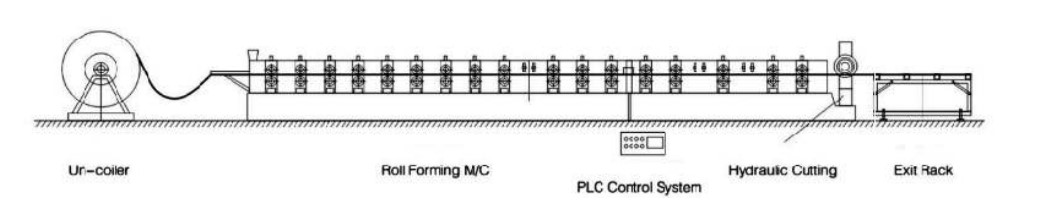

Production process:

Uncoiler-Feeding material into machine→Roll forming→hydraulic cutting→ Products receiving

Packing list of the Double Layer Roofing Roll Forming Machine:

| No. | Name | Quantity |

| 1 | Manual/hydraulic Decoiler | 1 set |

| 2 | Main roll former | 1 set |

| 3 | Control system | 1 set |

| 4 | Hydraulic system | 1 set |

| 5 | Product Run-out table | 1 set |

The technical specifications of the Double Layer Roofing Roll Forming Machine:

| Item | Name | Specifications |

| 1 | Raw material | GI&PPGI |

| 2 | Raw material thickness | 0.3-0.8mm |

| 3 | Decoiler | 5T |

| 4 | Felt device | Available |

| 5 | Roller station | 18stations |

| 6 | Roller material | 45# steel |

| 7 | Shaft diameter | 80mm |

| 8 | Shaft material | 45# steel |

| 9 | Transmission | By double chains |

| 10 | Motor power | 7.5kw |

| 11 | Machine frame | 350H steel |

| 12 | Cutting type | Electric Cutting device |

| 13 | Hydraulic power | 4kw |

| 14 | Cutting blade material | Cr12 quenched |

| 15 | Cutting tolerance | +/1mm |

| 16 | Control system | Delta/ Siemens PLC |

The function of the Double Layer Roofing Roll Forming Machine:

1. Efficient production:

The Double Layer Roofing Roll Forming Machine can process two layers of materials simultaneously, greatly improving production efficiency and reducing labor costs.

2.Cost savings:

The double-layer design reduces the footprint of equipment and factory buildings, lowering investment costs. In addition, the produced tiles can be directly used for the roofs and walls of buildings, further saving on building material costs.

3.Diversified applications:

The Double Layer Roofing Roll Forming Machineproduces a wide variety of tiles, suitable for different building types and uses, such as indoor and outdoor walls, roofs, highway guardrails, etc., meeting various needs.