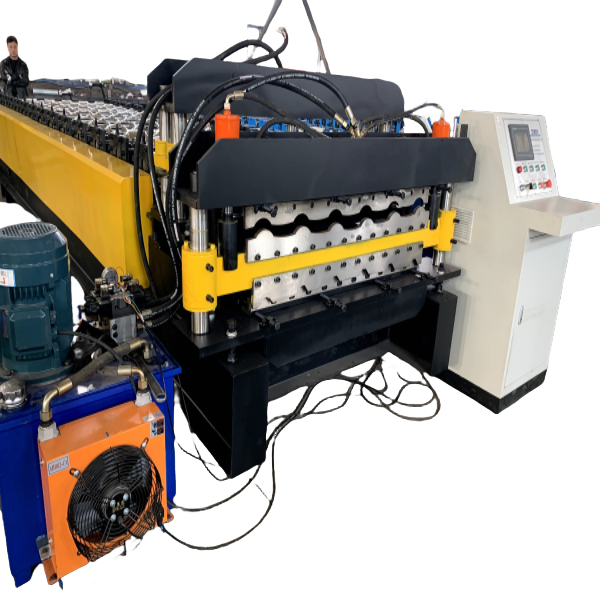

This double layer machine can produce two different shapes of tiles,it can save cost and space for the manufacturing. The following double layer machine is delivered to Chile.

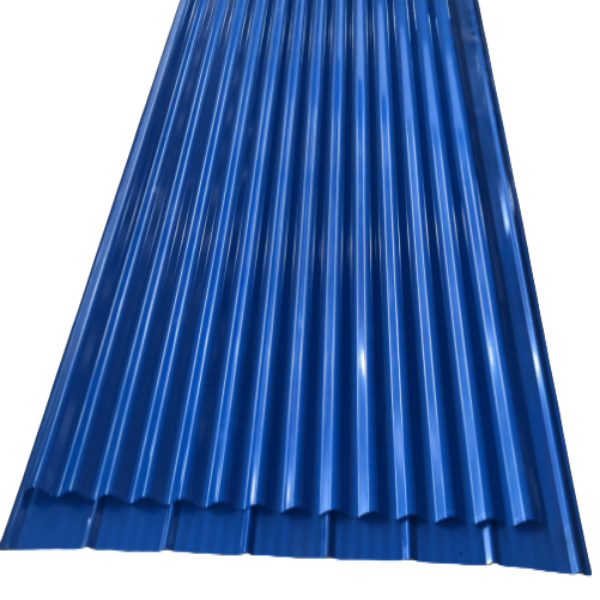

The profile drawing of the first layer machine:

![]()

The profile drawing of the second layer machine:

![]()

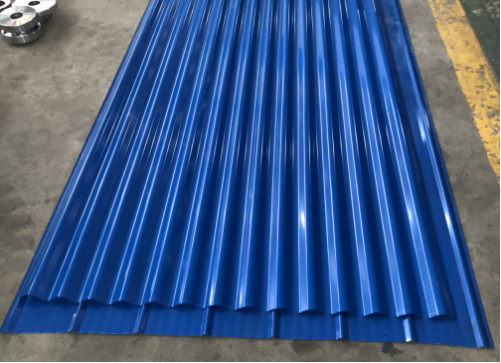

The pictures for the finished product:

Packing list of the Double Layer Roof Sheet Roll Forming Machine:

| No. | Name | Quantity |

| 1 | Manual/hydraulic Decoiler | 1 set |

| 2 | Main roll former | 1 set |

| 3 | Control system | 1 set |

| 4 | Hydraulic system | 1 set |

| 5 | Product Run-out table | 1 set |

The technical specifications of the Double Layer Roof Sheet Roll Forming Machine:

| Item | Name | Specifications |

| 1 | Raw material | GI&PPGI |

| 2 | Raw material thickness | 0.3-0.8mm |

| 3 | Decoiler | 5T |

| 4 | Felt device | Available |

| 5 | Roller station | 14+16stations |

| 6 | Roller material | 45# steel |

| 7 | Shaft diameter | 80mm |

| 8 | Shaft material | 45# steel |

| 9 | Transmission | By double chains |

| 10 | Motor power | 5.5kw |

| 11 | Machine frame | 350H steel |

| 12 | Cutting type | Hydraulic cutting |

| 13 | Hydraulic power | 5.5kw |

| 14 | Cutting blade material | Cr12 quenched |

| 15 | Cutting tolerance | +/1mm |

| 16 | Control system | Delta/ Siemens PLC |

Now I will introduce the double layer roof sheet roll forming machine,this type is very popular.

Part 1:Decoiler

1.Function:To support the coil for production

2.Types:Manual and automatic for option

3.Capacity:Normal 5 tons,other weight also can customized

Part 2:Roll former

(1)The feeders:our feeders use the stainless rollers to avoid the material from scratching.

(2)Cutting device:Stronger guide post cutting device and the blade holder which will make the cutter working more stable and long life-time.

Part 3:Control system

Our machine adopt famous brand in the control system,such as Siemens PLC and touch screen,Schneider low voltage apparatus and omron encoder,these brand electric parts have after-sale service in the whole world which is more convenient for customer.

Part 4: Hydraulic system:

Our hydraulic system is equipped with the fan cooling system,it can cool down the oil during long time working or at hot weather.