Double layer machine of glazed sheet and arc sheet rolling machine for Antigua.

By the double layer design, it can save cost and space for the manufacturing. Here I will take the following drawing for example to show you how the machine is designed. The following double layer machine is delivered to Antigua.

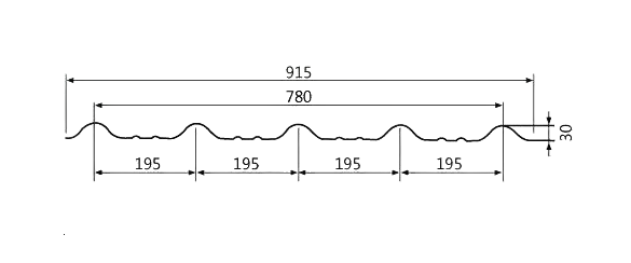

The profile drawing of the first layer machine:

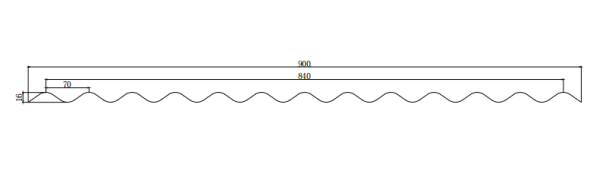

The profile drawing of the second layer machine:

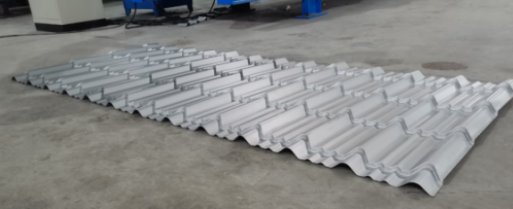

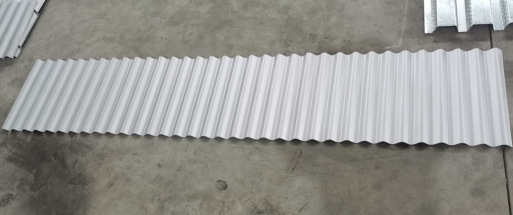

The pictures for the finished product:

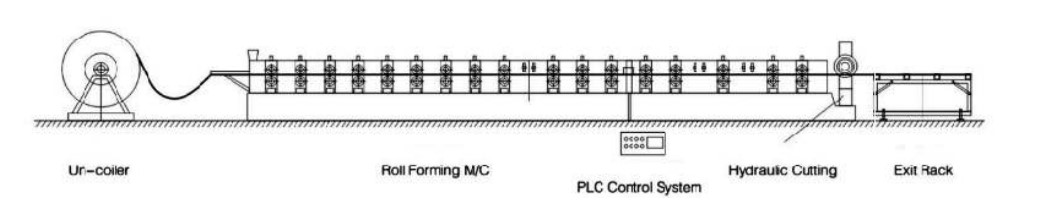

Production process:

Uncoiler-Feeding material into machine→Roll forming→hydraulic cutting→ Products receiving

Packing list of the Double Layer Roof Sheet Roll Forming Machine:

| No. | Name | Quantity |

| 1 | Manual/hydraulic Decoiler | 1 set |

| 2 | Main roll former | 1 set |

| 3 | Control system | 1 set |

| 4 | Hydraulic system | 1 set |

| 5 | Product Run-out table | 1 set |

The technical specifications of the Double Layer Roof Sheet Roll Forming Machine:

| Item | Name | Specifications |

| 1 | Raw material | GI&PPGI |

| 2 | Raw material thickness | 0.3-0.8mm |

| 3 | Decoiler | 5T |

| 4 | Felt device | Available |

| 5 | Roller station | 14+16stations |

| 6 | Roller material | 45# steel |

| 7 | Shaft diameter | 80mm |

| 8 | Shaft material | 45# steel |

| 9 | Transmission | By double chains |

| 10 | Motor power | 5.5kw |

| 11 | Machine frame | 350H steel |

| 12 | Cutting type | Hydraulic cutting |

| 13 | Hydraulic power | 5.5kw |

| 14 | Cutting blade material | Cr12 quenched |

| 15 | Cutting tolerance | +/1mm |

| 16 | Control system | Delta/ Siemens PLC |

The function of the Double Layer Roof Sheet Roll Forming Machine:

1.Simultaneous production of double-layer tiles:

The double Layer Roof Sheet Roll Forming Machinecan produce two layers of roof tiles on the same machine, significantly improving production efficiency compared to traditional single-layer tile machines.

2.High degree of automation:

Equipment is usually equipped with advanced automation control systems and human-machine interfaces, with simple and intuitive operation. Workers can quickly master operational skills through simple training, reducing the labor intensity and error rate of manual operation.

3.Rapid production cycle:

Due to its efficient production process, the double Layer Roof Sheet Roll Forming Machinecan complete the entire pressing process from raw materials to finished products in a relatively short time, greatly shortening the production cycle.

4.Reduce material waste:

The double Layer Roof Sheet Roll Forming Machineadopts a double-layer material composite process, which reduces the production of scraps and thus reduces the consumption of raw materials.

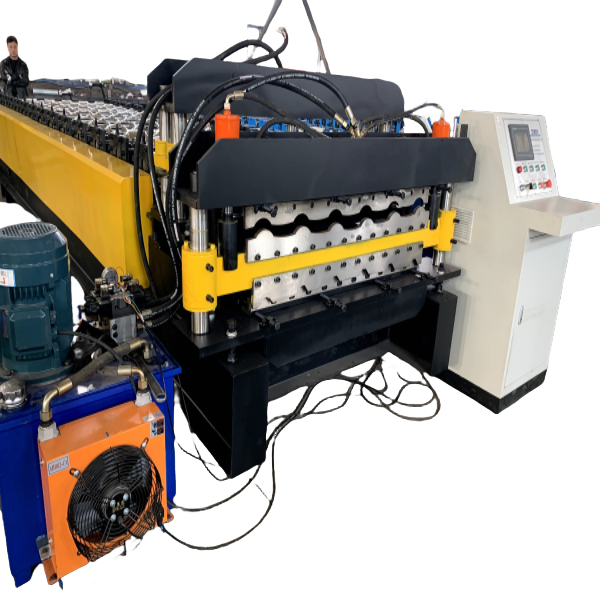

Machine photos:

Some details of the Double Layer Roof Sheet Roll Forming Machine: