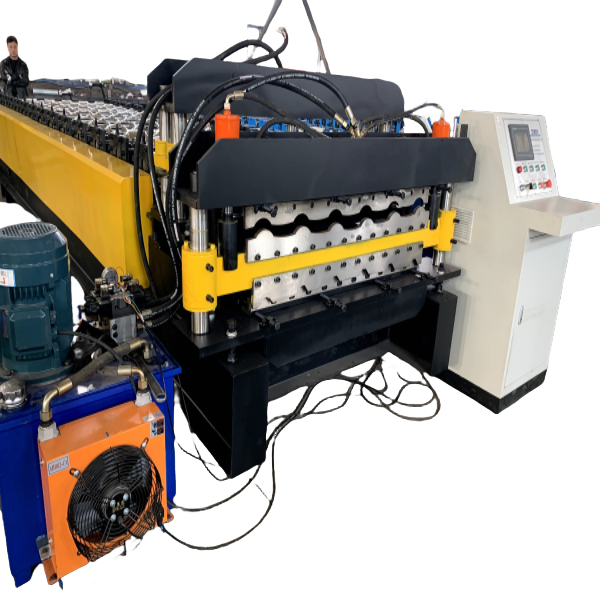

Stable transmission:Double chain and gear drive,keynote rollers design.

Product Diversity:Can produce two different product in the same machine ,can save less space.

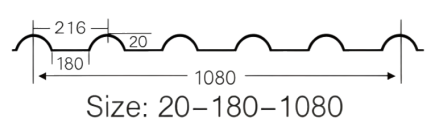

The profile drawing of the first layer machine:

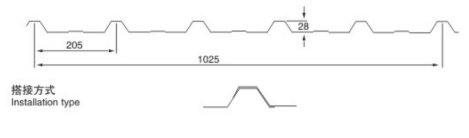

The profile drawing of the second layer machine:

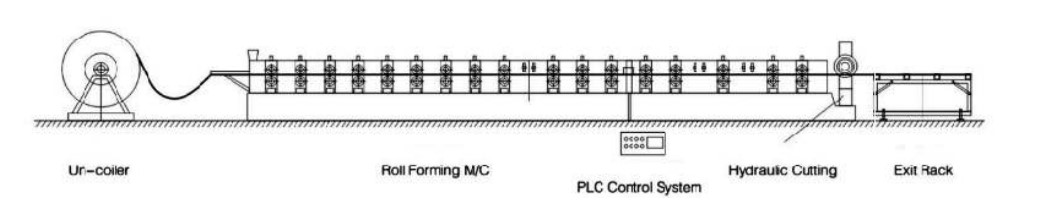

Production process:

Uncoiler-Feeding material into machine→Roll forming→hydraulic cutting→ Products receiving

Packing list of the Double Layer Roof Sheet Roll Forming Machine:

| No. | Name | Quantity |

| 1 | Manual/hydraulic Decoiler | 1 set |

| 2 | Main roll former | 1 set |

| 3 | Control system | 1 set |

| 4 | Hydraulic system | 1 set |

| 5 | Product Run-out table | 1 set |

The technical specifications of the Double Layer Roof Sheet Roll Forming Machine:

| Item | Name | Specifications |

| 1 | Raw material | GI&PPGI |

| 2 | Raw material thickness | 0.3-0.8mm |

| 3 | Decoiler | 5T |

| 4 | Felt device | Available |

| 5 | Roller station | 13+18stations |

| 6 | Roller material | 45# steel |

| 7 | Shaft diameter | 80mm |

| 8 | Shaft material | 45# steel |

| 9 | Transmission | By double chains |

| 10 | Motor power | 5.5kw |

| 11 | Machine frame | 350H steel |

| 12 | Cutting type | Hydraulic cutting |

| 13 | Hydraulic power | 5.5kw |

| 14 | Cutting blade material | Cr12 quenched |

| 15 | Cutting tolerance | +/1mm |

| 16 | Control system | Delta/ Siemens PLC |

The function of the Double Layer Roof Sheet Roll Forming Machine:

1.Multifunctionality:

The double Layer Roof Sheet Roll Forming Machine can produce two different cross-sectional panels on the same equipment, which not only saves space but also improves work efficiency.

2.Efficient production:

The double Layer Roof Sheet Roll Forming Machine usually consists of parts such as feeding, forming, and post forming cutting. The produced glazed tiles have a smooth and beautiful appearance, uniform paint patterns, and good strength. They are suitable for the surfaces and walls of industrial and civil buildings, such as factories, warehouses, locomotive depots, aircraft hangars, sports halls, exhibition halls, etc.

3.Economical and affordable:

The double-layer design makes the equipment cost lower than two single-layer machines, suitable for small and medium-sized enterprises with limited space and budget. In addition, the device is easy to operate, has low maintenance costs, and is suitable for on-site construction use.

4.Reasonable structure:

The double Layer Roof Sheet Roll Forming Machine is mainly composed of several parts, including a feeding platform, a forming host, a forming shear device, a hydraulic station, and a computer control system. The upper and lower layer conversion operation is simple, just control each layer through the conversion button on the electrical control cabinet.

Some details of the Double Layer Roof Sheet Roll Forming Machine: