Cutting to Length & Slitting Lines, a comprehensive solution for precise and efficient metal processing. This advanced equipment combines the functionality of cutting to length and slitting in a single integrated line, offering versatility and productivity. The precision cutting mechanism ensures clean and uniform cuts, enabling you to achieve the desired lengths for various materials. The slitting process allows for the creation of multiple strips with accuracy and consistency. With user-friendly controls and adjustable settings, this line allows for easy customization and quick setup. Built with top-quality components, our Cutting to Length & Slitting Lines guarantee durability and reliable performance, optimizing your metal processing operations and maximizing output.

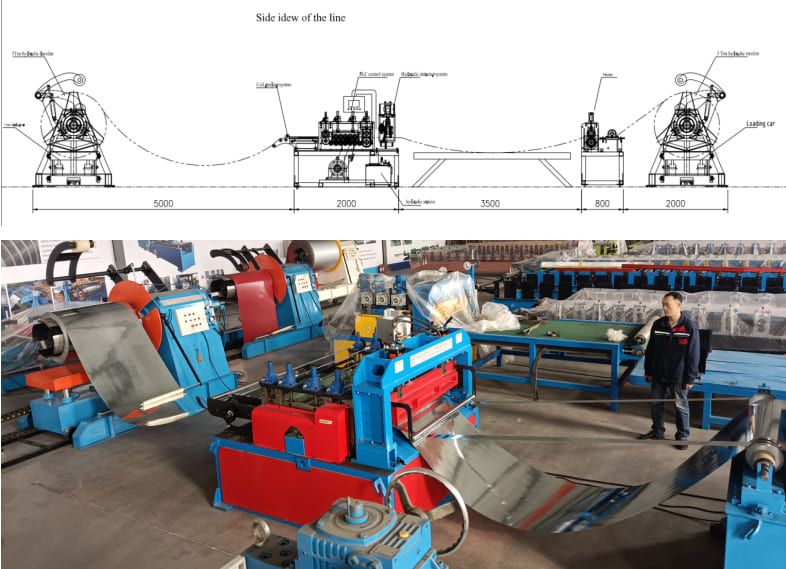

Thin sheet metal slitting line with cut to length function for gutter, ridge cap is a tool for an quite economic tool for metal processing. This tool is also could be used to separate coils: for example if the big coil is 10 ton, but you want to make it two small coil like 2 ton or 3 ton or others and then this machine can help you. But it only could be used to process the thin coil Max thickness to 1.5mm and it can slit Max 5 pieces. Here is the machine working flow for your reference:

Here are more detail information of each elements for your reference:

| Packing list | ||

| Part 1 | Hydraulic decoiler with loading car 5 Ton | Optional manual one |

| Part 2 | Leveling,Slitting and Cut to length part | |

| Part 3 | PLC control system | |

| Part 4 | Hydraulic pump station | |

| Part 5 | Tension stand | |

| Part 6 | Hydraulic recoiler with loading car 5 Ton | Optional manual one |

PART 1: HYDRAULIC DECOILER

- Supporting the coils and doing uncoiling.

- It adopts the hydraulic oil cylinder to make the decoiler expandable and fit to the inner diameter(508-610mm)of coils. It is equipped with the

- Motor drive the coils running and can do forward and reverse running as well as do the decoiling with

- Loadingcapacity: ≤5 tons

- Max coil width: 1250 mm

- Feeding speed: 0-20m/min (adjustable) Driving motor power: 5kw

- Hydraulic motor power: 4.0kw

- Structure: welding by the steel plates and profiled The decoiler is equipped with the pneumatic brake system

| Part 2: Leveling, slitting and cut to length | |

| Feeding device | Adjustable |

| Leveling roller number | 13 rollers, 5up 6down |

| Leveling roller diameter | 50mm |

| Roller material | High grade 45# steel |

| Shaft diameter | 80 mm |

| Work speed | 0-15 m/min |

| Machine basic frame | Steel plate welded |

| Power system | Motor drive, driven by the speed reducer and then give power to gear. |

| Driving power | 7.5 kw |

| Material thickness adjusting | By lifter, convenient to adjust for different thickness of material |

Hydraulic recoiler 5 ton With the loading car With pressing arm

The press arm is fixed on the recoiler to wind each coils one by one and ensure the recoiling quality.

Loading capacity:≤6 tons

Inner diameter: 470-530mm

Main motor power: 11KW

Hydraulic station: 4KW

Coil width: 1250mm

The oil cylinder stroke of the loading trolley is longer, which is suitable for loading and unloading steel coils with smaller outer diameter.