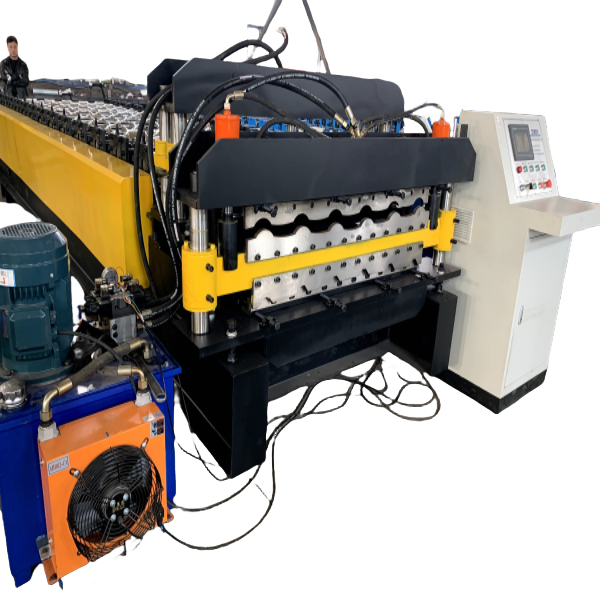

Double Layer Roof Sheet Roll Forming Machine, a versatile and efficient solution for roofing sheet manufacturing. This advanced equipment allows simultaneous roll forming of two different layers, optimizing production time and resources. With precision-engineered rollers, it ensures impeccable shaping and uniformity in every sheet. The user-friendly interface enables easy adjustments, offering flexibility in creating various roofing profiles. Constructed with robust materials, this machine guarantees durability and stability for prolonged use. Whether you’re producing metal, steel, or aluminum sheets, the Double Layer Roof Sheet Roll Forming Machine is the key to enhancing productivity and delivering high-quality roofing materials for diverse construction needs.

Double Layer Roof Sheet Roll Forming Machine

Design Idea

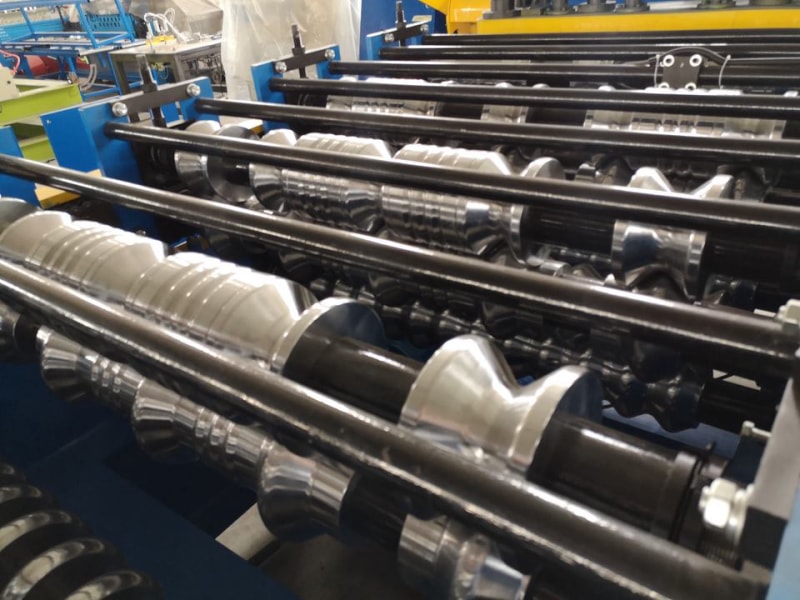

Stable Transmission: Double chain and gear drive,keynote rollers design.

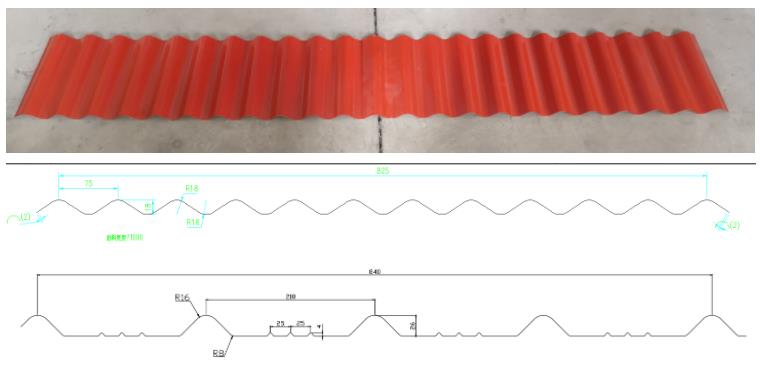

Profile drawing for reference:

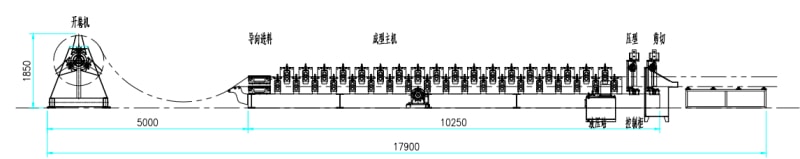

Processing Flow

R Panel Roll Forming Machine Hot Sale To America | |

Raw Material | PPGI,PPGL |

Material Thickness:24/26 Gauge (0.4-0.6 Mm) | |

Machine Frame | 350mm H Beam Structure, With 18mm Welded Steel Middle Support Plate. |

Material Of Rollers | High grade 45# forged steel,Chromed treatment |

Forming Stations | Up layer :16 rows,lower layer:17 rows |

Diameter Of Shafts | Φ80mm Solid |

Material Of Shafts | High Grade 45#,With Heat Treatment |

Forming Speed | 15 M/Min |

Voltage | 380v/50hz/3p (As Requested) |

Transmission Way | By 1 Inch Chain (Double Chains) |

Main Motor | 5.5 KW |

Cutting Blade Material | Gcr12 quenched treatment |

Cutting Type | hydraulic post cutting |

Driving Method | By pillar type Cylinder |

PRODUCT DISPLAY