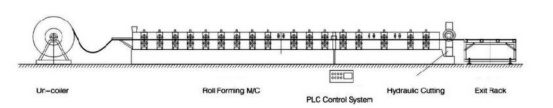

Corrugated Roofing Sheet Roll Forming Machine

is a specialized equipment for producing circular roof tiles. Corrugated roof tiles can add unique beauty to buildings, making the roof lines smoother and more artistic. It is suitable for various architectural styles, such as ancient buildings, modern villas, park and outdoor buildings, etc.

Production process:

Uncoiler-Feeding material into machine→Roll forming→hydraulic cutting→ Products receiving

Packing list of the Corrugated Roofing Sheet Roll Forming Machine :

| No. | Name | Quantity |

| 1 | Manual/hydraulic Decoiler | 1 set |

| 2 | Main roll former | 1 set |

| 3 | Control system | 1 set |

| 4 | Hydraulic system | 1 set |

| 5 | Product Run-out table | 1 set |

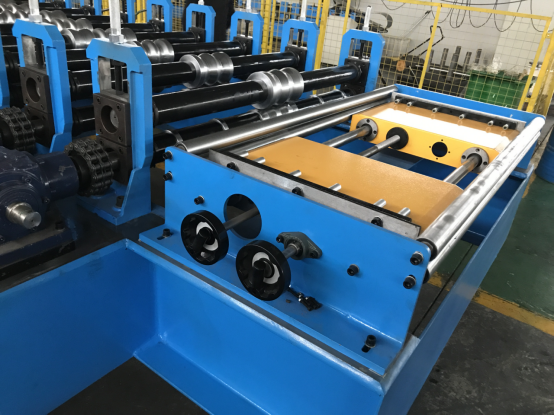

The technical specifications of the Corrugated Roofing Sheet Roll Forming Machine :

| Item | Name | Specifications |

| 1 | Raw material | Galvanized steel,Q235 |

| 2 | Raw material thickness | 0.18-0.28mm |

| 3 | Decoiler | 5T |

| 4 | Felt device | Available |

| 5 | Roller station | 19stations |

| 6 | Roller material | 45# steel |

| 7 | Shaft diameter | 80mm |

| 8 | Shaft material | 45# steel |

| 9 | Transmission | By Gearbox |

| 10 | Motor power | 7.5kw |

| 11 | Machine frame | 400mm H beam structure |

| 12 | Cutting type | Hydraulic cutting |

| 13 | Hydraulic power | 5.5kw |

| 14 | Cutting blade material | Gcr12 quenched treatment |

| 15 | Cutting tolerance | +/1mm |

| 16 | Control system | Delta/ Siemens PLC |

The function of the Corrugated Roofing Sheet Roll Forming Machine :