Corrugated Roofing Sheet Roll Forming Machine, offered by ZTRFM Forming. This advanced industrial device is designed for efficient production of high-quality corrugated roofing sheets. With precision engineering, the machine effortlessly shapes metal sheets into precise and uniform corrugated profiles. Its automated operations ensure consistent results, optimizing production efficiency and reducing labor costs. The Corrugated Roofing Sheet Roll Forming Machine offers versatility in creating various sizes and designs of corrugated roofing sheets, meeting diverse construction needs. It is an essential tool for manufacturers aiming to deliver reliable and durable corrugated roofing sheets for commercial, industrial, and residential buildings, providing superior weather protection and aesthetics.

ZTRFM new materials have the following functions and are ideal materials to replace ordinary metal roof tiles

- Acid and alkali resistance, corrosion resistance

- Aging resistance, 30 year color fastness

- Thermal insulation, environmental protection and energy conservation

- Convenient installation and labor saving

- The service life is 2-3 times of that of ordinary metal roof tiles, and the price is about 130% of that of ordinary color steel tiles

ZTRFM corrugated roofing sheet roll forming machine, patented design Both ordinary PPGI GI PPGL GL roofing materials and new multifunctional roofing materials designed and produced by ZTRFM can be used.

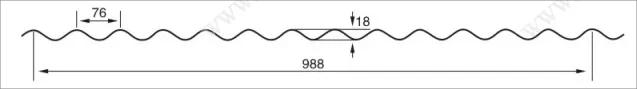

Profile drawing as follows

Finished corrugated roofing sheet

Feature and technical parameter of corrugated roofing sheet roll forming machine.

Both common metal roofing materials and new multi-function roofing materials can be used, the machine of other suppliers can only use ordinary metal roofing materials.

- Easy to install, easy to operate,

- Longer service life, low failure rate

- On year warranty, lifelong technical support.

- Roller Shaft: 70mm, solid 45# steel, quenched treatment

- Rollers: 45# steel, Chromed treatment, improve the hardness and prevent abrasion, anti corrosion increase of service life

- Rolling station: 18 stations

- Production speed: 0-15m/min

- PLC control system: Delta, touch screen

- Inverter: Delta

- Cutting blade: Cr12MoV, heat treatment

- Low voltage electric parts: Schneider brand

- Encode: Omron

- Double pillar structure hydraulic cutting system

- Hydraulic station with cooling system, in case the oil temperature getting hot when the machine working for hours continuously, ensure the hydraulic oil in a constant temperature to have enough power for cutting device

- All the tubes and wires will be marked by the numbers or letters,so that it will be very easy to connect for the new.

More pictures of corrugated roofing sheet roll forming machines