The Corrugated Fencing Panel Roll Forming Machine offers several key advantages. First, it efficiently produces high-quality corrugated fencing panels with precision and uniformity. Second, its automated operations streamline the production process, reducing labor costs and improving productivity. Third, the machine’s versatility allows for various panel designs and sizes to meet diverse fencing requirements. Fourth, it ensures consistency in panel production, resulting in reliable and durable fencing solutions. Lastly, the Corrugated Fencing Panel Roll Forming Machine’s advanced technology enhances efficiency and accuracy, making it an essential tool for manufacturers seeking top-notch fencing solutions for commercial, industrial, and residential applications.

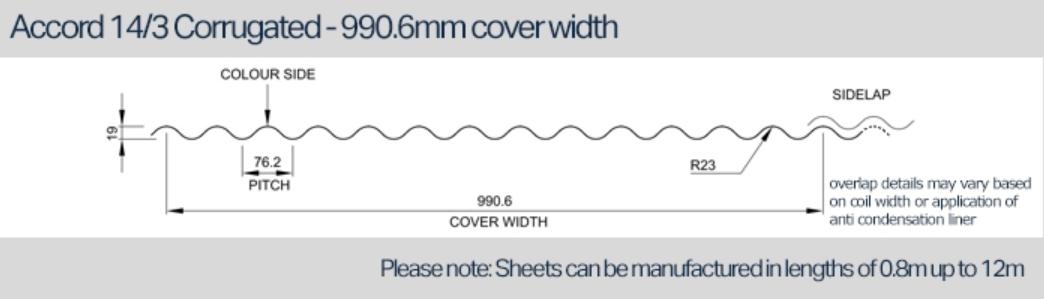

Corrugated steel sheets (also known as sinusoidal, corrugated iron or wriggly tin) have been around for many years and are still very popular today. Giving a more traditional look, 3″ corrugated steel sheets are usually specified as the only roof cladding to be used in conservation areas. The formed color steel sheets can be cut to length as required from 0.5m up to 12m, making them suitable for any domestic, industrial or agricultural application.

Here are popular profiles of corrugated metal sheet in UK(England).

Corrugated steel sheet are not only made for roofing applications, Corrugated metal fencing is becoming more and more popular for both residential and commercial buildings, and agricultural fencing needs. Corrugated metal fence panels are perfect for privacy, security, windbreak or decorative fencing needs.

Unpainted and untreated steel allows the surface to rust and form a natural iron oxide finish.

What is the application of ZHONGTUO corrugated roof roll forming machine?

Zhongtuo corrugated steel sheet roll forming machine is mainly producing steel roofing, siding panel and metal fencing, we can design and customize the corrugated roofing and panel forming machine according to customer’s requirements.

The advantage of corrugated roof roll forming machine.

1.The system is easy to operate and use. PLC: Delta, Siemens or Mitsubishi (Can customize as customer require)

2.the surface of the final product is very smooth and beautiful without any scratch on the surface.

3.customized:design the machine according to your specification and profile drawing.(for your reference)