In the dynamic world of construction, precision and efficiency are paramount. The Metal Stud & Track Roll Former emerges as a key player, offering a specialized solution for the streamlined production of metal studs and tracks. In this article, we will explore the significance of this machine, its applications, benefits, and how it is reshaping the landscape of construction with its ability to efficiently create durable and versatile metal framing components.

Section 1: Unveiling the Metal Stud & Track Roll Former

What Is a Metal Stud & Track Roll Former?

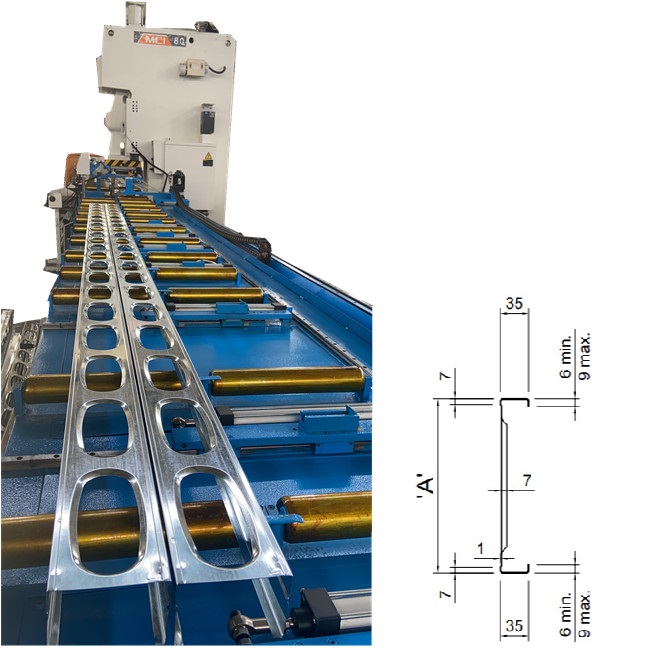

A Metal Stud & Track Roll Former is a specialized piece of equipment designed to fabricate metal studs and tracks used in framing systems for both interior and exterior walls. This machine utilizes a precise roll forming process to transform flat metal sheets into the specific profiles needed for constructing sturdy and dimensionally accurate framing components.

Significance in Construction

This machine holds immense significance in construction projects where speed, accuracy, and structural integrity are crucial. By automating the production of metal studs and tracks, it streamlines the framing process, contributing to faster and more efficient construction timelines.

Section 2: How Metal Stud & Track Roll Formers Work

The Mechanism

The machine operates by feeding flat metal coils through a series of rollers and forming dies. These components gradually shape the metal into the specific profiles of studs and tracks, ensuring consistent dimensions and structural integrity. The roll forming process is precise, allowing for high-volume production with minimal material waste.

Versatility in Construction

Metal Stud & Track Roll Formers are versatile, capable of producing a variety of profiles and sizes to meet the diverse requirements of construction projects. Whether it’s for residential, commercial, or industrial applications, these machines adapt to the demands of modern architecture.

Section 3: Applications and Versatility

Interior Framing Systems

The primary application of these machines is in the creation of metal studs and tracks for interior framing systems. These components serve as the skeleton for walls, providing structural support for finishes such as drywall.

Exterior Wall Construction

Metal studs and tracks produced by these machines are also used in exterior wall construction. The durability and dimensional accuracy of the framing components contribute to the stability and longevity of the overall structure.

Section 4: Advantages of Metal Stud & Track Roll Formers

Precision and Consistency

The roll forming process ensures precision and consistency in the dimensions of metal studs and tracks. This accuracy is crucial for achieving a tight fit during construction and ensuring the overall stability of the building.

Efficiency and Cost Savings

Metal Stud & Track Roll Formers automate the production process, significantly reducing labor costs and material waste. The efficiency of these machines contributes to overall cost savings in construction projects.

Design Flexibility

These machines offer design flexibility, allowing for the creation of various profiles and sizes to accommodate different architectural styles and project specifications. This adaptability aligns with the evolving demands of modern construction.

Section 5: The Future of Metal Stud & Track Roll Formers in Construction

Technological Innovations

Ongoing advancements in Metal Stud & Track Roll Formers include improved controls, real-time monitoring, and enhanced material handling capabilities. These innovations contribute to increased efficiency and the seamless integration of metal framing components into various construction applications.

Sustainable Construction Practices

As the construction industry continues to prioritize sustainability, Metal Stud & Track Roll Formers play a vital role. Their resource-efficient production and durability align with the global commitment to environmentally responsible construction practices.

Conclusion

The Metal Stud & Track Roll Former stands as a symbol of efficiency and precision in the construction industry. Its ability to automate the production of metal studs and tracks streamlines the framing process, contributing to faster and more cost-effective construction projects. As construction practices evolve, these machines are set to remain indispensable, offering a sustainable and innovative solution for producing metal framing components that uphold the standards of modern architecture. With ongoing technological advancements and a heightened focus on sustainable construction, Metal Stud & Track Roll Formers will continue to redefine the norms for efficient and resilient building practices worldwide.