Ceiling keel machine is a professional mechanical equipment used for producing keel materials for building decoration, widely used in the installation of ceiling and partition systems. The ceiling keel machine is mainly used in the construction and decoration industry, such as the installation of ceilings and partitions in hotels, shopping malls, office buildings, factories, and other places.

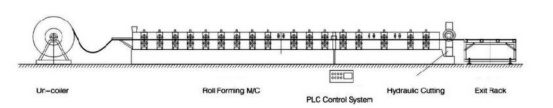

Production process:

Uncoiler-Feeding material into machine→Roll forming→hydraulic cutting→ Products receiving

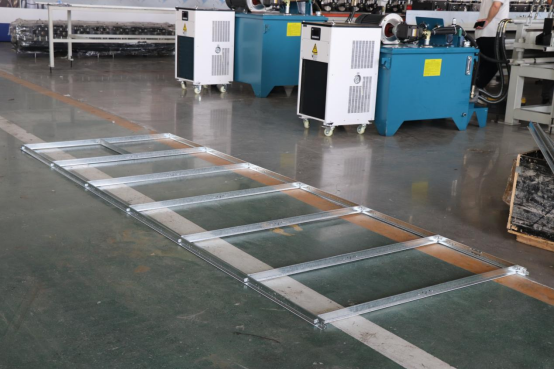

Packing list of the Ceiling keel machine :

| No. | Name | Quantity |

| 1 | Manual/hydraulic Decoiler | 1 set |

| 2 | Main roll former | 1 set |

| 3 | Control system | 1 set |

| 4 | Hydraulic system | 1 set |

| 5 | Product Run-out table | 1 set |

The technical specifications of Ceiling keel machine :

| Item | Name | Specifications |

| 1 | Raw material | GI&PPGI |

| 2 | Raw material thickness | 0.6-1.2mm |

| 3 | Decoiler | 3T |

| 4 | Felt device | Available |

| 5 | Roller station | 18stations |

| 6 | Roller material | 45# steel |

| 7 | Shaft diameter | 50mm |

| 8 | Shaft material | 45# steel |

| 9 | Transmission | By gear |

| 10 | Motor power | 5.5kw |

| 11 | Machine frame | Vertical arch frame structure |

| 12 | Cutting type | Hydraulic cutting |

| 13 | Hydraulic power | 3kw |

| 14 | Cutting blade material | Cr12 quenched |

| 15 | Cutting tolerance | +/1mm |

| 16 | Control system | Delta/ Siemens PLC |

The function of the Ceiling keel machine :

1.High security:

The ceiling keel machine adopts PLC control and has multiple safety protection measures to ensure safety during the production process. The bed of the equipment is made of welded steel plates and undergoes tempering treatment to eliminate internal stress, avoid deformation of the machine body, and further enhance the safety of the equipment.

2.Easy to operate:

The transmission structure of the ceiling keel machine adopts a gearbox transmission to ensure that the equipment can operate for a long time and with high strength. The device is easy to use, easy to learn and use, and can be operated independently after simple training. The mold has high precision, long service life, beautiful appearance, and easy assembly.

3.High cost-effectiveness:

The ceiling keel machine has minimal material loss during production and adopts a mechanical design of back punching and back cutting. When there is a size deviation, it can be immediately stopped for correction, avoiding material waste. At the same time, the operating cost is low, and one person can complete the operation, which improves production efficiency and reduces costs.

4. High production efficiency:

The ceiling keel machine has a high shipping rate and installation capacity, and occupies a small area. There are multiple protective measures in the equipment composition, and the body material is steel plate, which is not easily deformed; The frame structure is made of cast iron material, which has strong stress and long service life; The hardness of molds and other materials is very high.