The ceiling keel machine is used to manufacture keel materials for ceilings, which can be processed quickly, accurately, and conveniently, providing a solid foundation for the construction of lightweight ceilings. The ceiling keel machine can manufacture various specifications and models of light steel keels, suitable for partition wall construction, making the partition effect more solid and stable.

Production process:

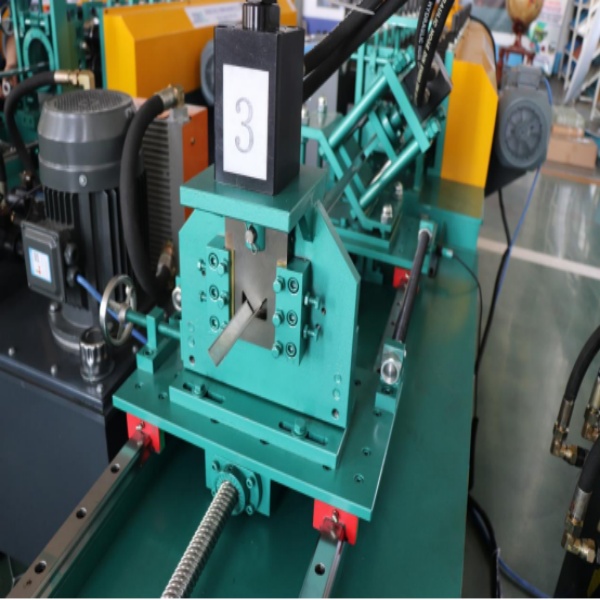

Uncoiler-Feeding material into machine→Roll forming→hydraulic cutting→ Products receiving

Packing list of the Ceiling keel machine :

| No. | Name | Quantity |

| 1 | Manual/hydraulic Decoiler | 1 set |

| 2 | Main roll former | 1 set |

| 3 | Control system | 1 set |

| 4 | Hydraulic system | 1 set |

| 5 | Product Run-out table | 1 set |

The technical specifications of Ceiling keel machine :

| Item | Name | Specifications |

| 1 | Raw material | GI&PPGI |

| 2 | Raw material thickness | 0.6-1.2mm |

| 3 | Decoiler | 3T |

| 4 | Felt device | Available |

| 5 | Roller station | 11stations |

| 6 | Roller material | 45# steel |

| 7 | Shaft diameter | 40mm |

| 8 | Shaft material | 45# steel |

| 9 | Transmission | By gear |

| 10 | Motor power | 5.5kw |

| 11 | Machine frame | Vertical arch frame structure |

| 12 | Cutting type | Hydraulic cutting |

| 13 | Hydraulic power | 3kw |

| 14 | Cutting blade material | Cr12 quenched |

| 15 | Cutting tolerance | +/1mm |

| 16 | Control system | Delta/ Siemens PLC |

The function of the Ceiling keel machine :

1.The ceiling keel machine can conveniently and quickly cut keel materials, without the need for a large amount of time and labor costs required by traditional manual cutting, improving production efficiency.

2.The ceiling keel machine can press flat light steel materials into the required model and angle, ensuring the accuracy and consistency of the materials and improving the overall structural strength.

3.The ceiling keel machine can bend and process flat light steel keel materials according to the required angle and length, and the processed products can be used as needed.