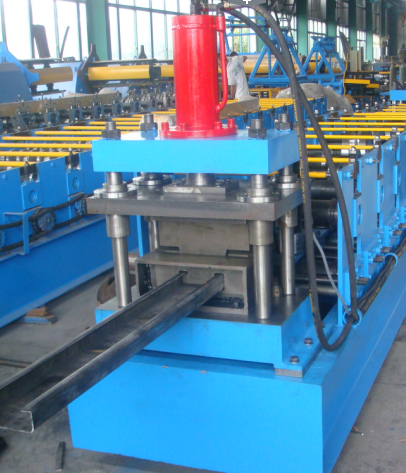

CZpurlin roll forming machine are suitable for various environments and application scenarios, and can be quickly installed and constructed in factory manufacturing, shortening the construction period. Its lightweight and high-strength characteristics make the installation process more convenient and suitable for various building needs. Due to its fast changeover and efficient production capacity, CZ steel machines can significantly shorten production cycles and reduce production costs.

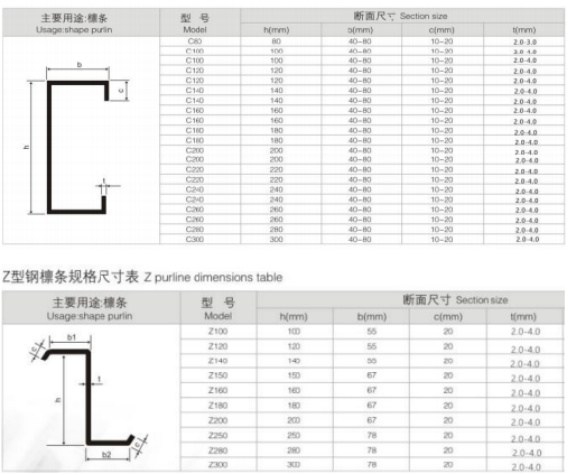

The profile drawing:

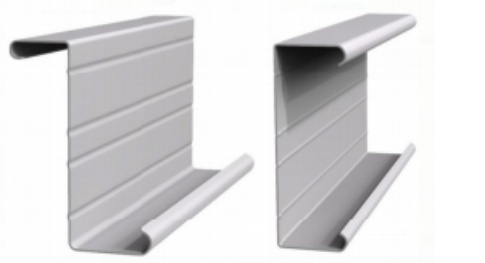

The pictures for the finished product:

Production process:

Uncoiler-Feeding material into machine→Roll forming→hydraulic cutting→ Products receiving

Packing list of the C Z Purlin roll forming machine:

| No. | Name | Quantity |

| 1 | Manual/hydraulic Decoiler | 1 set |

| 2 | Main roll former | 1 set |

| 3 | Control system | 1 set |

| 4 | Hydraulic system | 1 set |

| 5 | Product Run-out table | 1 set |

The technical specifications of theC Z Purlin roll forming machine:

| Item | Name | Specifications |

| 1 | Raw material | GI&PPGI |

| 2 | Raw material thickness | 1.5-4.0mm |

| 3 | Decoiler | 5T |

| 4 | Felt device | Available |

| 5 | Roller station | 14stations |

| 6 | Roller material | 45# steel |

| 7 | Shaft diameter | 80mm |

| 8 | Shaft material | 45# steel |

| 9 | Transmission | By double chains |

| 10 | Motor power | 18.5kw |

| 11 | Machine frame | 400H steel |

| 12 | Cutting type | Hydraulic cutting |

| 13 | Hydraulic power | 11kw |

| 14 | Cutting blade material | Cr12 quenched |

| 15 | Cutting tolerance | +/1mm |

| 16 | Control system | Delta/ Siemens PLC |

The function of the C Z Purlin roll forming machine:

1.Quick changeover and efficient production:

The C Z Purlin roll forming machine has the function of quick changeover, which can be completed within three minutes and adapt to the production of various specifications of CZ purlin finished products. In addition, the infinite transformation system can be adjusted in millimeters within specifications, which is not only suitable for standard board types but also for producing non-standard board types, greatly improving production efficiency and flexibility.

2.High precision and stability:

TheC Z Purlin roll forming machine adopts a coaxial design, which reduces the problem of uneven height on both sides caused by broken shafts, ensuring the accuracy and stability of the product. Infinite technology enables devices to continuously obtain products of any specification within the specified range, further improving product quality and consistency.

3.Multifunctionality and ease of use:

TheC Z Purlin roll forming machine is not only suitable for the production of CZ steel, but can also produce other products such as C-shaped steel, achieving multi use with one machine. In addition, the machine is easy to operate and suitable for the production of various specifications of CZ purlin products, reducing operational difficulty and training costs.