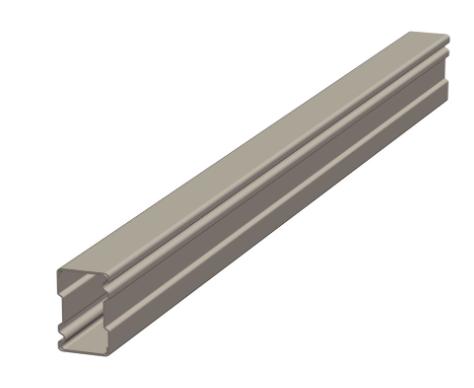

The Box Beam Roll Forming Machine is a state-of-the-art solution for manufacturing robust and precise box beams. This cutting-edge machine is designed to produce high-quality box beams with precision and efficiency. With automated controls and precision engineering, it ensures seamless and accurate roll forming, resulting in consistent and durable box beam profiles. The machine is versatile and can handle various materials like steel, aluminum, or other alloys, making it suitable for a wide range of structural and construction applications. Experience superior box beam production and elevate your projects with this reliable and high-performance Box Beam Roll Forming Machine, the perfect choice for strong and dependable structural components.

Box beam handle mainly wire mesh decks,cup style safety bars and fork entry bars. Beams are available in different sizes depending on load requirements,box beams are made with 2 inserted channels making them more resistant to collisions and rust, and providing more capacity than the competition.

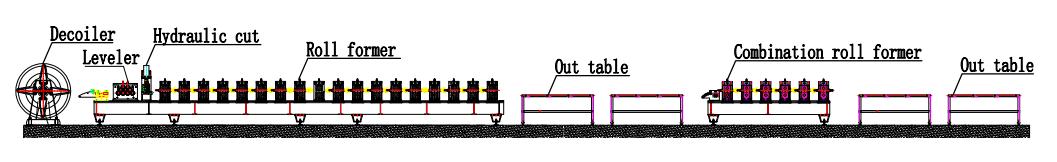

Our rollforming lines for box beam production includes special equipment to complete manufacturing of pallet rack beams, our machines are design and collaborate with client design elements to ensure high quality product output

Work flow of Box beam roll forming machine:

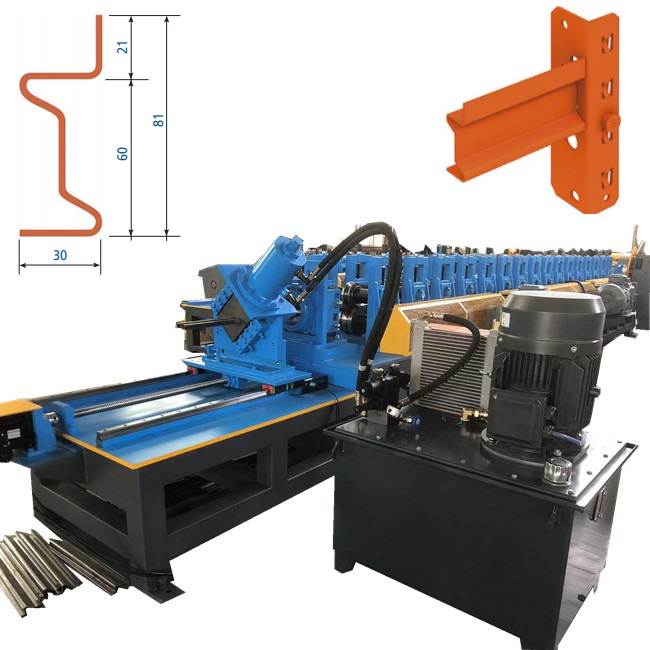

Main parameters

| Raw material | Galvanized steel |

| Mateial thickness | 1-1.6mm |

| Main power | 11KW |

| Voltage | 380V/50HZ/3P(Customized) |

| Roller stations | 15 rows |

| Forming speed | 15m/min |

| Roller material | Gcr15 steel |

| Shaft material | 40CR steel,75mm diameter,solid |