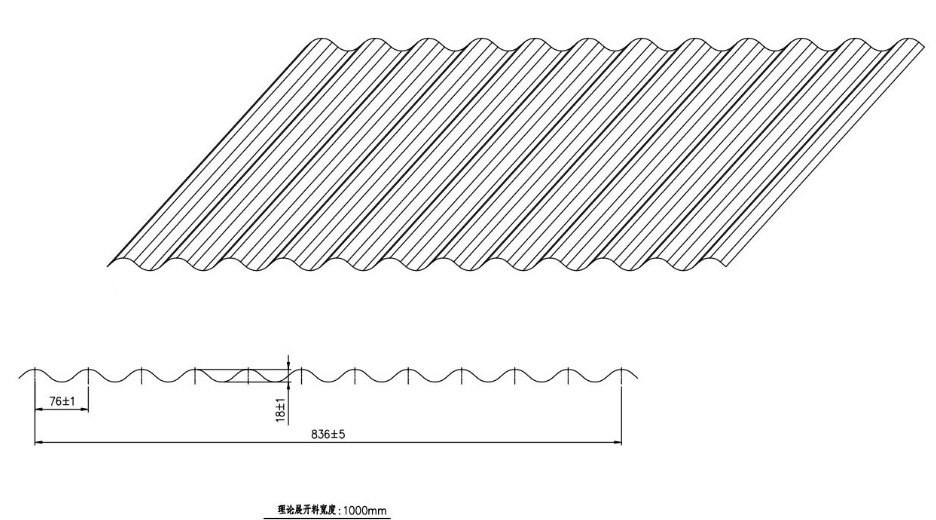

Corrugated roof tile machine is a mechanical equipment specifically used for producing tiles with circular arc shapes. It adopts advanced molding technology and materials, and through precise mechanical transmission and control systems, presses raw materials into tiles with circular arc shapes for roof covering of buildings, providing a beautiful appearance and good water proof performance.

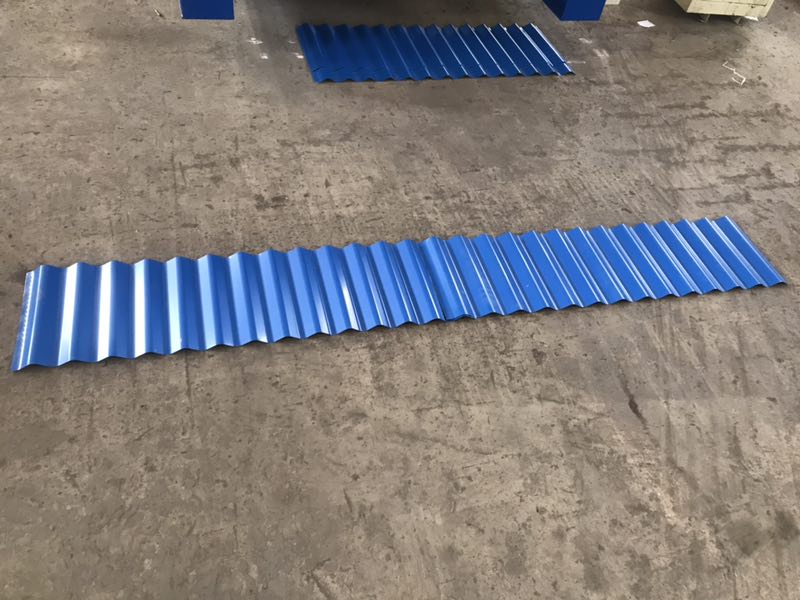

The pictures for the finished product:

Packing list of the corrugated roof tile machine:

| No. | Name | Quantity |

| 1 | Manual/hydraulic Decoiler | 1 set |

| 2 | Main roll former | 1 set |

| 3 | Control system | 1 set |

| 4 | Hydraulic system | 1 set |

| 5 | Product Run-out table | 1 set |

The technical specifications of the corrugated roof tile machine:

| Item | Name | Specifications |

| 1 | Raw material | GI&PPGI |

| 2 | Raw material thickness | 0.3-106mm |

| 3 | Decoiler | 5T |

| 4 | Felt device | Available |

| 5 | Roller station | 15stations |

| 6 | Roller material | 45# steel |

| 7 | Shaft diameter | 80mm |

| 8 | Shaft material | 45# steel |

| 9 | Transmission | By double chains |

| 10 | Motor power | 5.5kw |

| 11 | Machine frame | 350H steel |

| 12 | Cutting type | Hydraulic cutting |

| 13 | Hydraulic power | 5.5kw |

| 14 | Cutting blade material | Cr12 quenched |

| 15 | Cutting tolerance | +/1mm |

| 16 | Control system | Delta/ Siemens PLC |

The following is detailed introduction of each main elements of the corrugated roof tile machine:

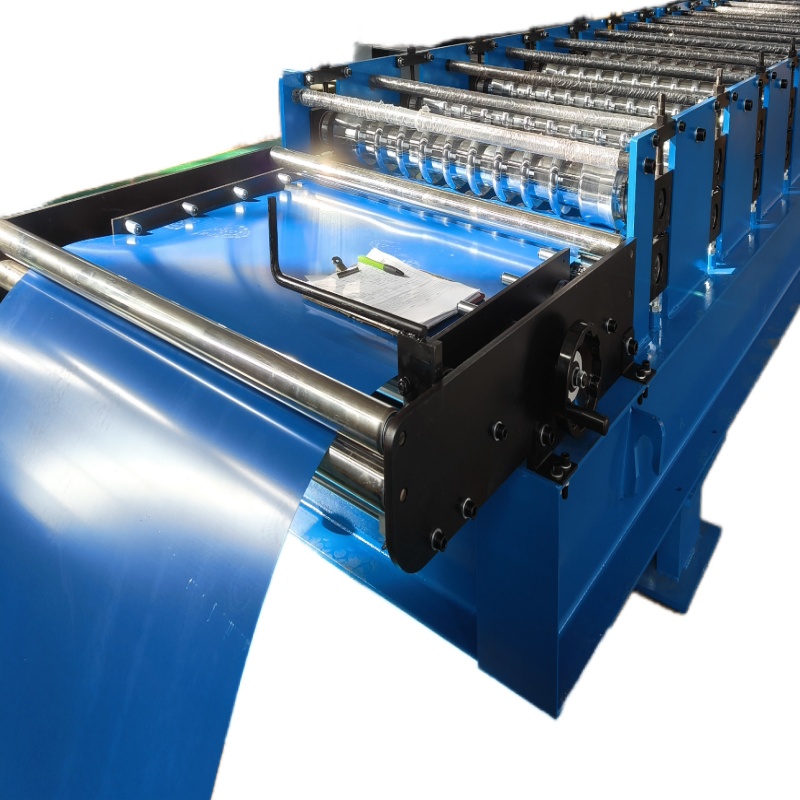

Part 1: 5T Hydraulic decoiler

1.Function:Supporting the coils and doing uncoiling.

2.Capacity:5 tons

3.Coil inner diameter:450-550 mm

4.Coil width:1250mm

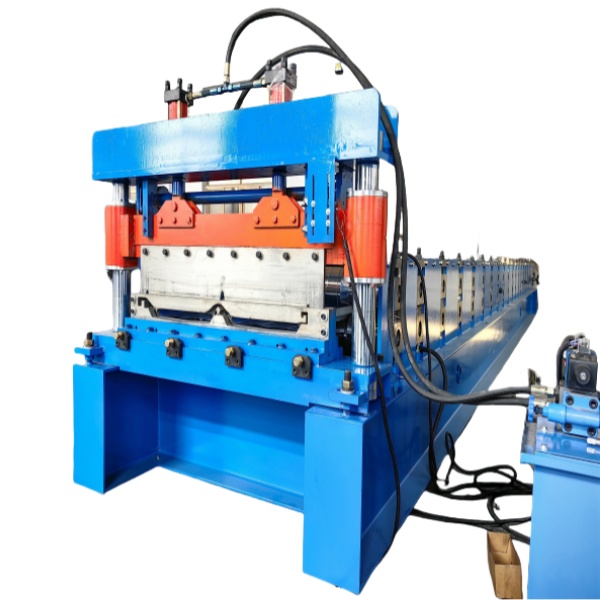

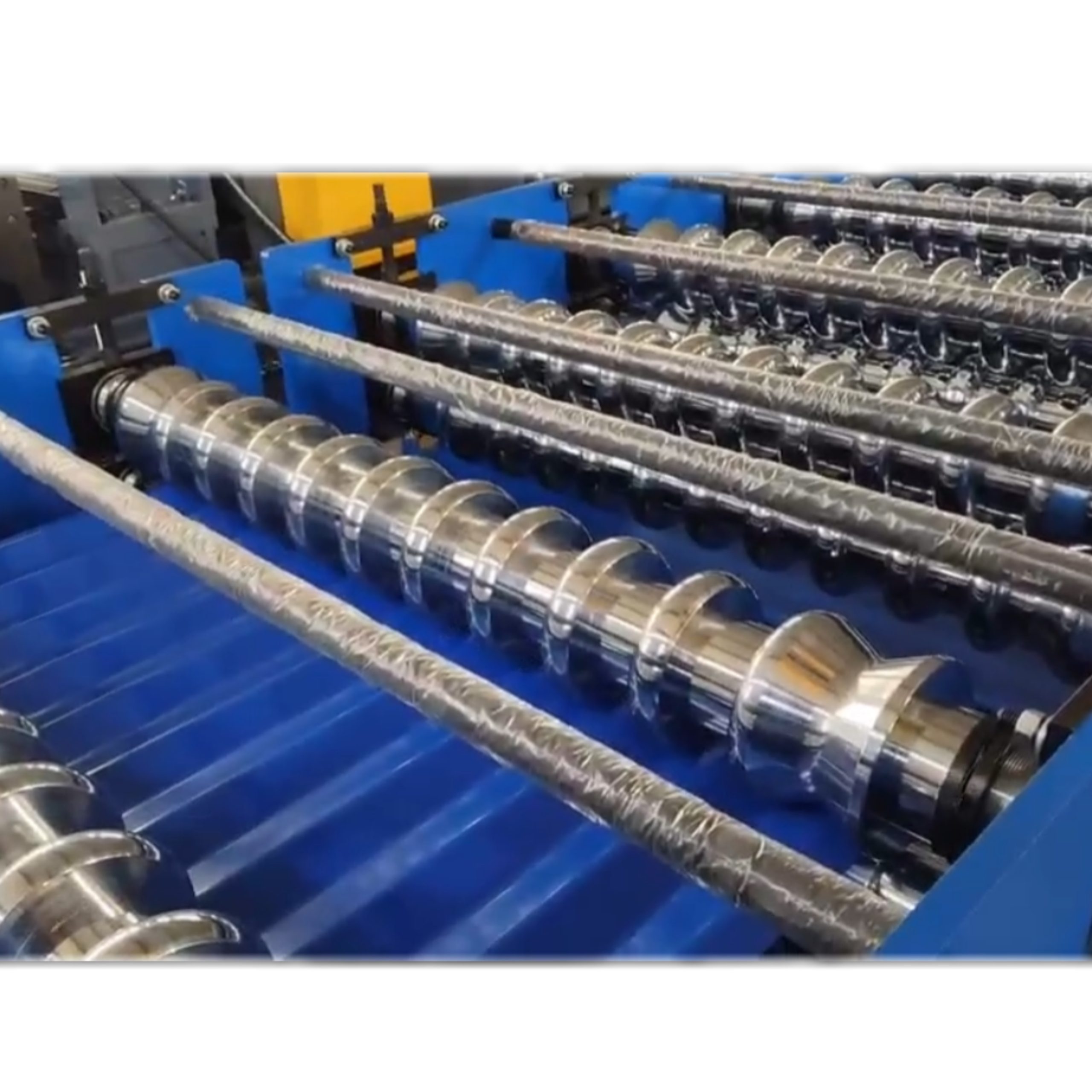

Part 2:Main roll forming machine

1.Shaft material:45# STEEL with quenched and tempering

2.Shaft diameter:80mm, solid shaft

3.Roller material: 45# steel

4.Roller station: 15stations

5.Work speed:About 0-20m/min

6.Machine body:350H steel welded

7.Bearing :Chinese famous brand Harbin

8.Work power:5.5 kw

9.Transmission :By double chain

10.Voltage:380V,50Hz,3 phase (customize)

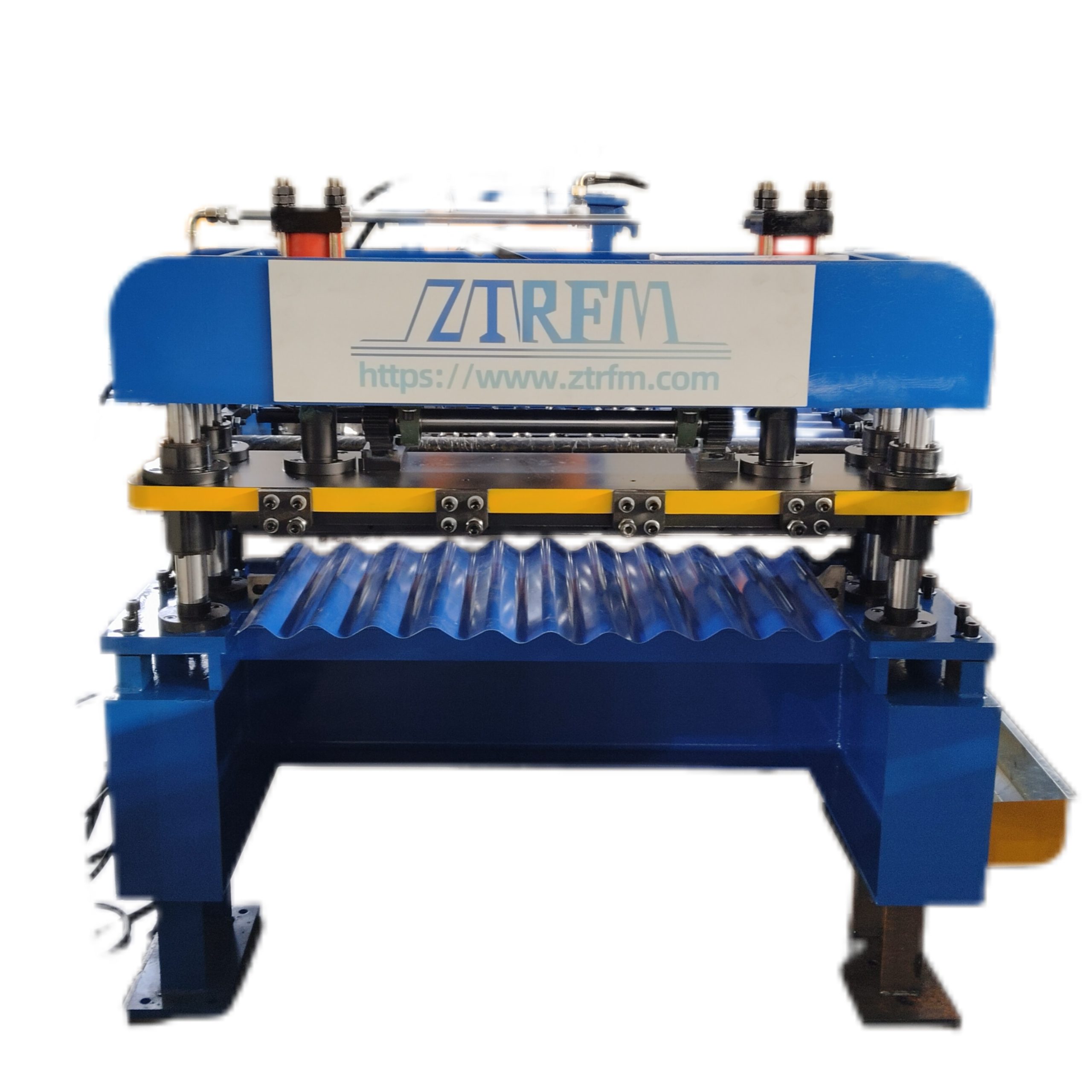

Part 3:Hydraulic cutting system

Part 3:Hydraulic cutting system

1.Work type:Hydraulic

2.Motor power:5.5 kw

3.Cutting blade material :GB-Cr12 mould steel with quenched treatment

4.Cooling system:By fan

Part 4: PLC Control system

Part 4: PLC Control system

1.PLC and Touch screen:Delta, wold famous brand

2.Electrical components:Schneider

3.Operating language:English and Chinese(or as requested)

4.Function:You can set the orders on this part,changing product length and quantity,it is really easy to operate,and there are aviation plugs to make it much easier to install the machine while it arrived.