Automatic C to Z Purlin Machine, the epitome of efficiency and versatility in purlin manufacturing. This cutting-edge equipment is designed to seamlessly switch between producing C and Z purlins with a simple adjustment, offering unparalleled convenience and flexibility. With precision-engineered rollers, it ensures uniform and accurate shaping, resulting in perfectly aligned purlins for quick installation. The fully automatic operation streamlines the manufacturing process, reducing labor and increasing productivity. Its user-friendly interface allows for easy customization, catering to various purlin sizes and profiles. Built with robust materials, this machine guarantees longevity and low maintenance, ensuring reliable performance for your construction needs. Experience effortless purlin production with the Automatic C to Z Purlin Machine and stay ahead in the industry.

Automatic one bottom control C to Z , CZ purlin rolling forming machine is the highest level C and Z purlin rolling forming machine. It can control the shape changing from to C to Z by one button control., it can reduce the requirements for professional and technical workers, improve work efficiency and reduce the waste of materials. Here we will take the following drawing profile for your reference:

Let me try to explain the sizes of range: for the C purlin, we divide it into three ranges, From C100 to C150,

From C 150 to C240mm, from C240 to C300 like this. In the different ranges, the thickness supported range is also different. The same working principle to the Z purling profiles.

Automatic CZ purlin rolling forming machine:

Supported Material:

1.5mm Minimum Thickness, 3.25mm Maximum Thickness 2.0mm for inspection

CR, HR, HRPO STEEL, Galvanized Plain CR Steel Yield strength: 450Mpa

Automatic CZ purlin rolling forming machine working layout:

More detail elements introduction, actual lots of elements are optional.

5Ton*650mm Hydraulic Un-coiler

Hydraulic system to expand coil inner hole;Pump motor:3KW;

Frequency Inverter to regulate turn speed;Motor:3KW

Coil Inner-diameter= 470-560mm. Coil Outer-diameter Max. 1600mm;

Link-connect expanding system

Load Capacity: Max. 5 Tons; Coil Width Max. 650mm;

Hydraulic Holder on the top to hold the sheet, keep press all the working time, special design on the hydraulic group

Pre-Leveling Device: In order to make the coil neat and clean, we design the special leveling system.

Meanwhile it also designed with the servo motor, when then coil width changing, it will do the size changing automatically.

Pre-shearing is optional: (You can choose to add or not.)

Sheet feeding guide section with width variation. Powered feed in rolls. Stop to Punch, stop to cut.

Hydraulic Pre-shearing device, manual control, only for cutting the first piece and the end piece of the sheet

Pre-cutting device, PLC control, purlin has bit open-up in both ends; panel, length min 2.5m

Hydraulic group, Pump motor =18.5KW (Before punching and after punching )

Total Three sets of punching stations

Station 1 : Web Punch – One round hole of dia 14mm

Station 2 : Web Punch – One pair of oval hole on web, size 14*22 mm

Station 3 : Flange Punch – One pair of oval hole on flange, size 14*22 mm

Extra set of die for punches of size 18*25 mm

They are exchangeable

Hydraulic group, Pump motor =18.5KW

For some holes, we do the punching before rolling forming, for some holes we do the punching after rolling forming. Here are some pictures for your reference:

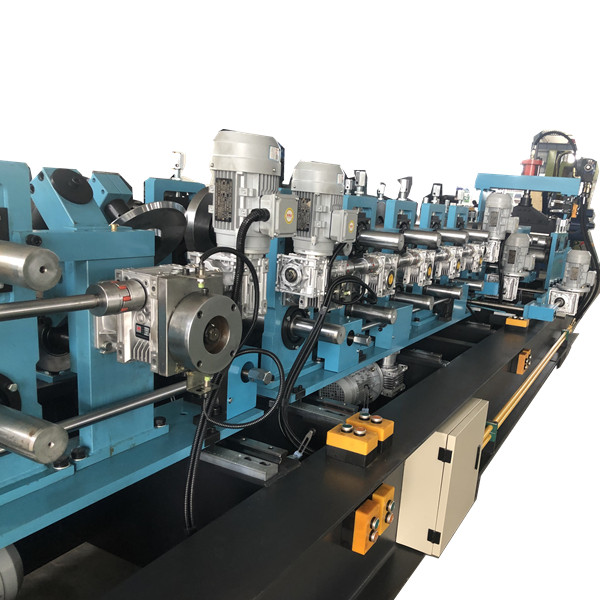

Automatic CZ purlin rolling forming machine

The feeding section with guide;

Gear/Sprocket driving, 18-step to form

Frame stand Construction,H beam base,with leveling bolts in the base to adjust the level

Rollers manufactured from Cr12(D3), Heat Treatment.

Shaft Diameter=Φ75mm, Precision Machined, heat Treatment

Sizes Changing: Movable design of one side/Dovetail slot structure.

By PLC control-setting size in PLC to reach the size requested (incl.width, flange, lip)

Changing from C to Z or Z to C automatically by PLC

Adjust the size of C, Z automatically according to setting parameters by PLC.

-setting size in PLC to reach the size requested (incl.width, flange, lip)

Main Motor=22 KW

Forming speed approx. 0-25m/min

Note: even if we design the sides and shape changing by PLC, we also allow you to do the changing by button control and handrail. In case some of mistake and then you can adjust a little bit.

Hydraulic post Innovative Cutting

Stop to Cut, Post Cut, Innovative cutting system, C/Z integrated & adjustable cutting mold

Cutting tool material: Cr12

Even if we call it as automatic but the size changing of cutter, we need to adjust by the worker. When the profile bigger or smaller, simple adjust it by the handrail up and down.

Automatic stacker part:

Equipment overview

C80-300 and Z100-300 full-automatic stackers can stack C/Z purlins with the same set of equipment. The whole set of equipment consists of servo motor, PLC and PRC touch screen, forming a complete control system. It has the advantages of simple structure, beautiful interface, reliable performance, convenient operation and high production efficiency.

Incremental encoder is used to fix the length. It can be controlled manually and automatically. The main low-voltage electrical components adopt international famous brands such as Schneider.

Automatic one bottom control C to Z CZ purline rolling forming machine working videos for your reference:

If you need more information, please contact us at any time.