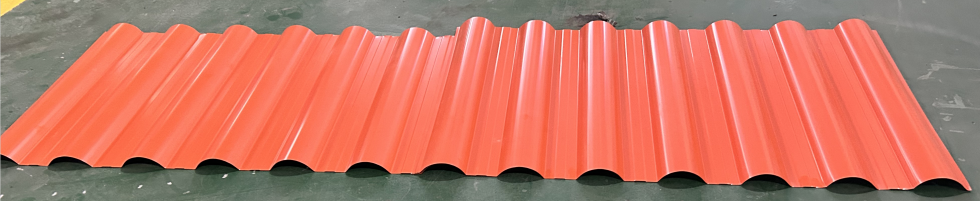

The Arc Tile with and without press Roofing Sheet Roll Forming Machine is a remarkable piece of equipment that serves the crucial purpose of manufacturing arc tiles. Arc tiles, known for their aesthetically pleasing and practical design, have become an extremely popular profile drawing all around the world, widely adopted in various roofing projects. This specific machine comes equipped with a distinctive and valuable feature, enabling it to produce roofing sheets both with the application of press and without it. This versatility allows it to meet different demands from construction sites, whether it’s for creating sturdier sheets with press for areas requiring more durability or lighter ones without press for other specific usage scenarios.

The pictures for reference:

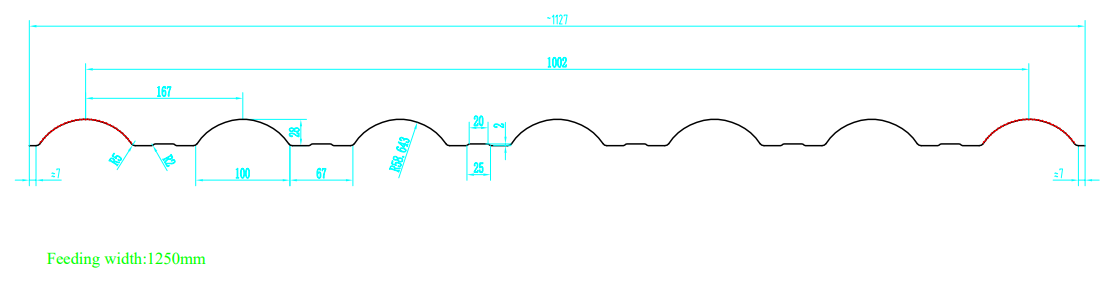

The profile drawing for reference:

The thickness of the raw material:

1.Tile with press:0.3-0.5mm

2.Tile without press:0.45-0.6mm

The overlap of the finished product:

Main Technical Specifications

1.Decoiler

Manual decoiler:

Hydraulic decoiler

2.The roll forming machine

| Raw material | Galvanized steel and Pre-painted steel |

| Raw material thickness | 0.3-0.5mm with press 0.45-0.6mm without press |

| Roller station | 20 stations |

| Roller material | 45# steel with quenched treatment |

| Shaft diameter | 80mm |

| Shaft material | 45# steel with tempered |

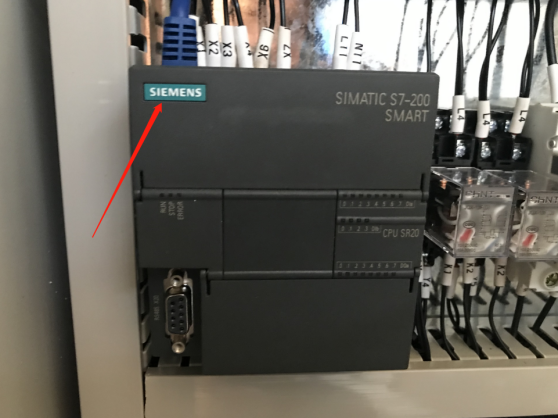

3.Control system

(1)We use world famous brand

Touch screen:Delta,Siemens,Mitsubishi

PLC:Delta,Siemens,Mitsubishi

Low voltage apparatus:Schneider

Encoder:Omron

(2) Use aviation plug for customer to easy connection power

4.Hydraulic system

Brand:Beijing Huade,Chinese famous brand

Magnetic valve:Big valve for good working

Cooling system:Fan cooling.