Al-Mg-Mn Corrugated Sheets For Roof panel Standing Seam Sheets rolling forming machine is designed to make the Al-Mg-Mn Corrugated Sheets in batch fully automatically. Aluminium is a silvery white Light metal with low density (2.75g/m * 3), excellent thermal conductivity and conductivity (the conductivity of aluminium is 64 times that of copper). If calculated by mass, the conductivity of aluminium is 200 times that of copper. Since a thin and solid oxide film can naturally form on the surface of aluminium, it can prevent some corrosive media from corroding it.

Magnesium – In practical metals, magnesium is light, with a density of only 1.74g/m * 3 (only 2/3 of aluminum). Its main characteristics are high elastic modulus, good vibration damping performance, and strong ability to withstand impact loads (twice that of aluminum). The advantage of magnesium is its relatively high specific strength (which is the ratio of strength to mass), with a specific strength of up to 133, which can be comparable to the specific strength of titanium.

Manganese – The main characteristics of manganese are its persistent strength and creep strength, good low-temperature impact toughness, and working temperatures up to 500 degrees Celsius and up to -100 degrees Celsius.

Vertical locking aluminum magnesium manganese roof system product model:

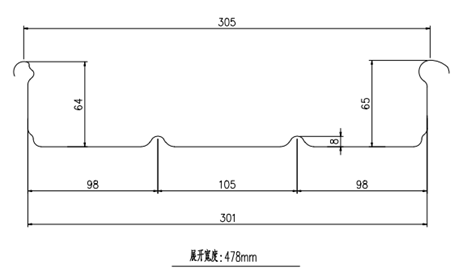

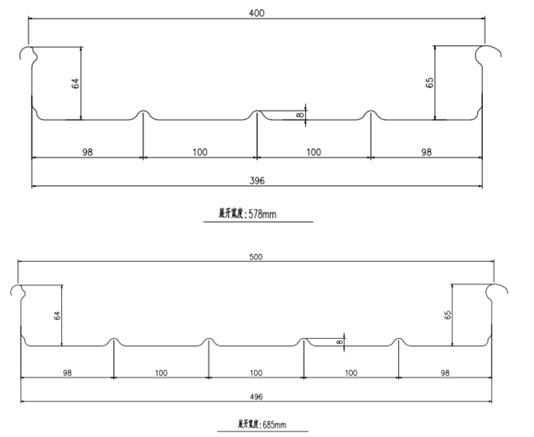

YX65-300, YX65-330, YX65-400, YX65-430, etc. are used as sector plates, curved plates, and sector bent plates

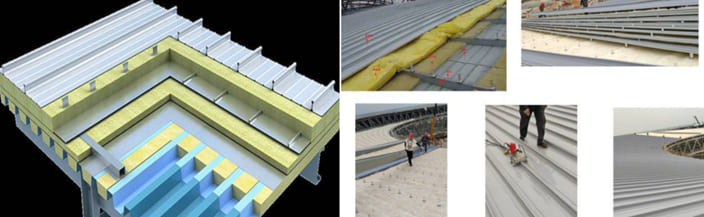

Aluminum magnesium manganese vertical locking aluminum magnesium manganese board, according to design requirements, can be refined into 6 layers during system construction:

- The roof layer adopts 0.9mmYX65-430 aluminum magnesium manganese board as the panel. The panel is a layer that directly contacts the atmosphere and rainwater. The waterproof design and treatment of the opposite layer are crucial. The selection of the height and direction of the vertical edge, as well as the construction treatment of special nodes, all determine the final waterproof result.

- The insulation layer is generally made of centrifugal glass fiber sound-absorbing cotton, mainly used for insulation and noise reduction (such as the noise caused by heavy rain and hail hitting the surface layer), and its top aluminum foil has good minor auxiliary waterproof function.

Here are some drawing profile for your reference:

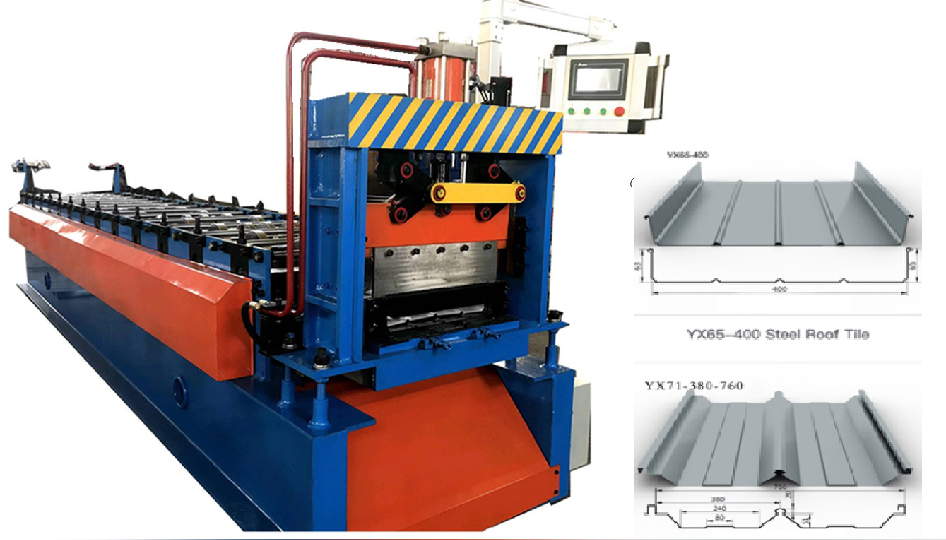

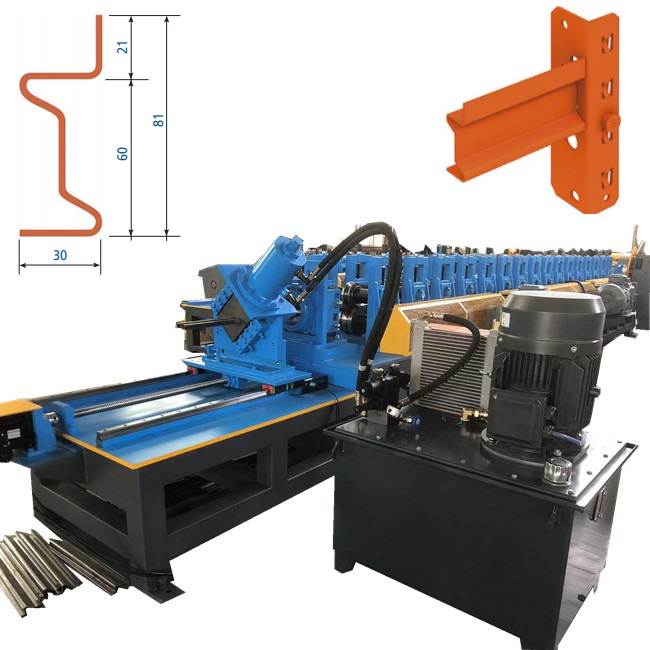

Al-Mg-Mn Corrugated Sheets For Roof panel Standing Seam Sheets rolling forming machine

This is the type, one machine for one profiles.

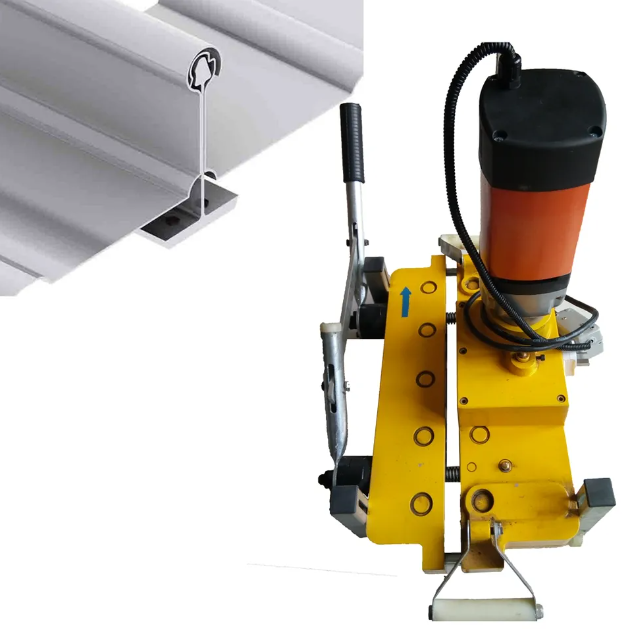

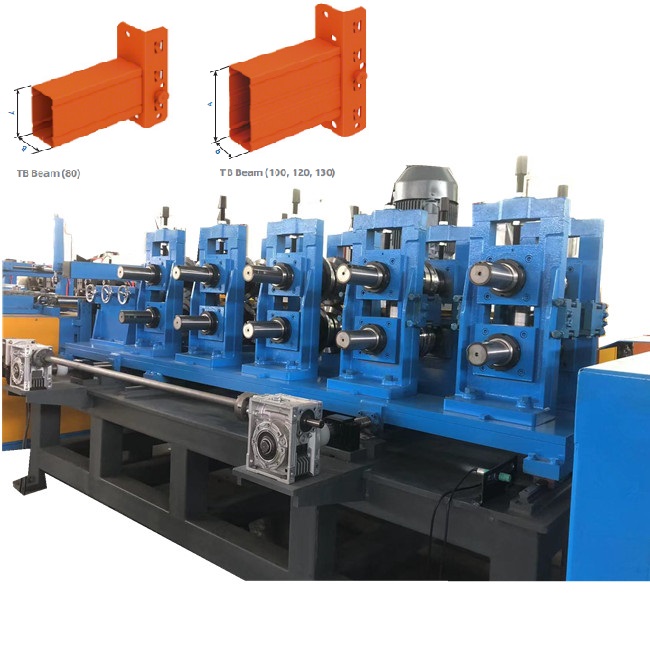

This is standing seam machine, one machine for many many sizes. You can choose which type you like. Here are more product pictures and where to use for your reference: And if you need the bending or curving machine, we can also make for you .