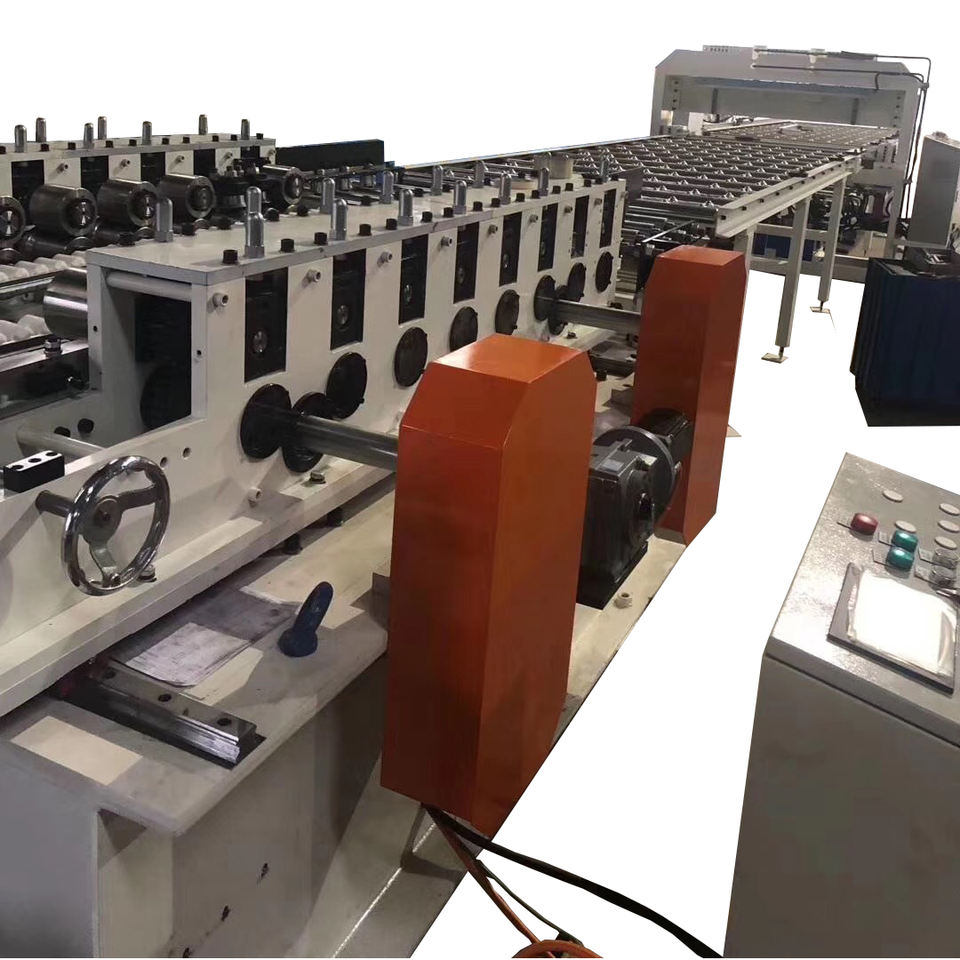

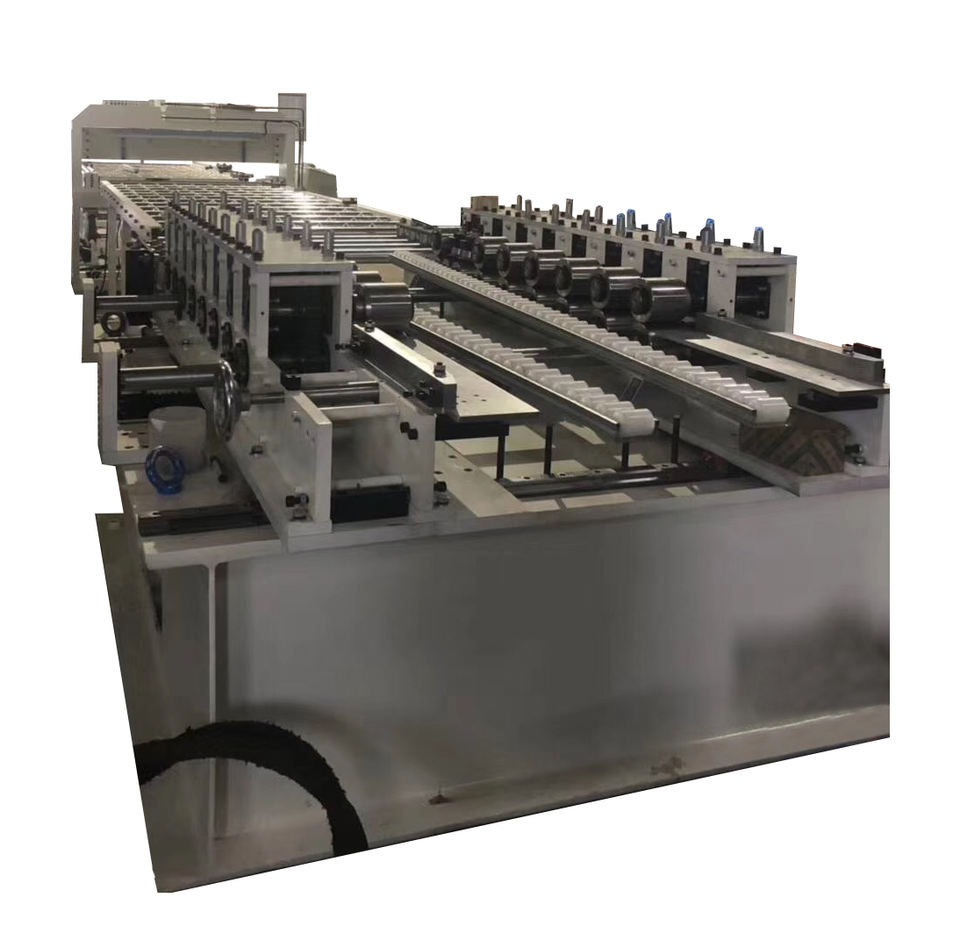

The Adjustable Width Linear Shelf Panel Roll Forming Machine is a cutting-edge and versatile solution for manufacturing linear shelf panels with adjustable widths. This state-of-the-art machine is specifically designed to produce high-quality shelf panels with precision and efficiency, allowing for easy adjustment of panel widths as per specific requirements. With automated controls and precision engineering, it ensures seamless and accurate roll forming, resulting in consistent and precise shelf panel profiles. The machine is compatible with various materials like steel, aluminum, or other alloys, making it ideal for a wide range of storage and shelving applications. Experience superior shelf panel production and maximize your storage flexibility with this reliable and high-performance Adjustable Width Linear Shelf Panel Roll Forming Machine.

Adjustable width linear shelf panel machine is designed to make shelf panels in batch automatically. This machine rollers can be adjusted to your drawing profile width and length. helf panel roll forming machine can be customized to your specification ideal for making different styles such as adjustable size, punching holes, embossing logo, making light or heavy duty panels and more…

1. The machine Is composed by the following elements:

2. 5 Ton passive decoiler or hydraulic decoiler

3. Leveling machine

4. Servo coil feeder

5. Fully automatic punching machines with the servo coil feeder another one.

6. Main rolling forming machine with cutting edge, bending

7. Hydraulic station

8. PLC control system

9. Receiving table

Sample picture for reinforcing shelf panel for heavy duty use

The below profile drawing sample picture shows there are 5 different sizes in width for the finish product:

Embossing Sample Picture:

Decoiler -> Leveling -> Servo Coil Feeder -> Hydraulic Punching -> Leveling -> Rollers – > Cutting + Bending -> Collecting Table

| Item | Specification |

| Main Forming Power | 380V/50HZ – 3 Phase |

| Working Speed | 6-8m/min |

| Feeding Thickness | 0.5mm – 1.0mm |

| Drive Type | Chain drive |

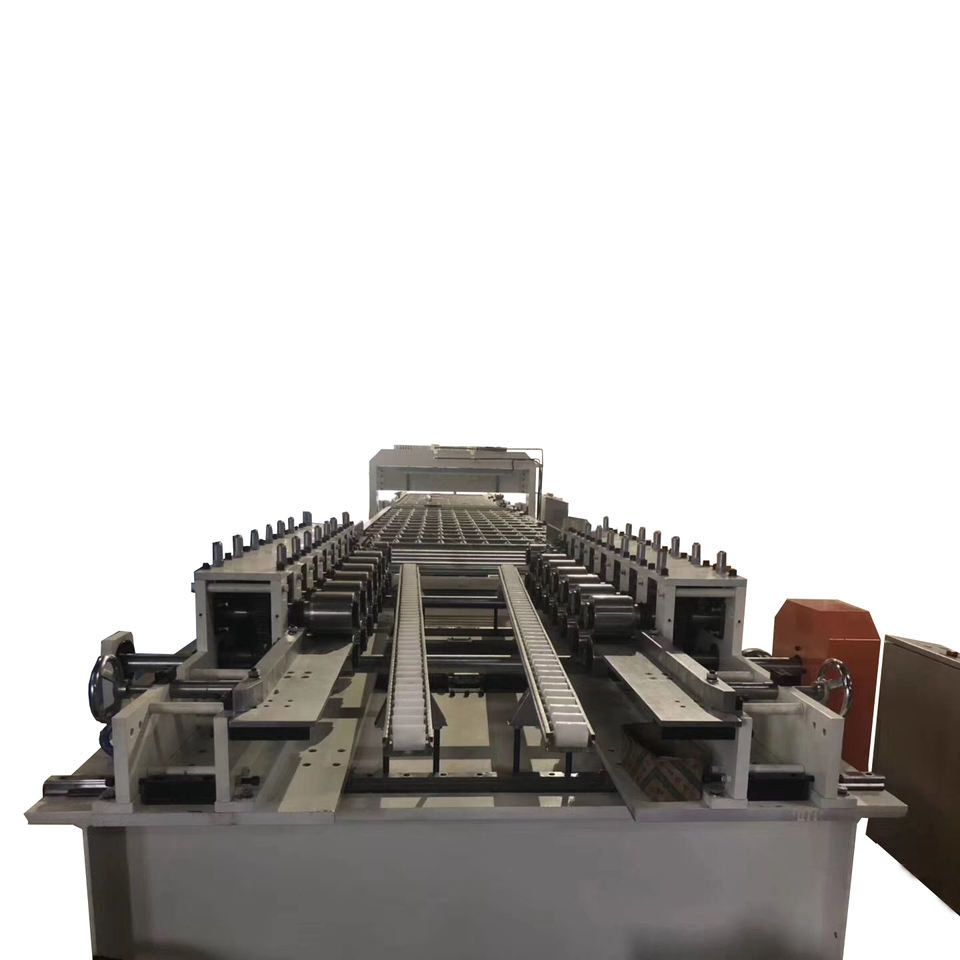

| Machine Architecture | Middle plate construction; 20mm thick |

| Roller Station | 35 (depending on drawing profile) |

| Roller Shaft | φ50mm Solid Shafts, 45# Steel |

| Roller | Gr15 quenching HRC58-62 C Chrome plated surface |

| Bearing | China Harbin famous brand |

| Main Frame | 400# H-beam Steel Welded |

| Color | Customizable |

Usage: It is used to support the steel coil and uncoil the material in a turnable way.

12t hydraulic decoiler specification:

| Item | Specification |

| Decoiling Type | Actively Uncoiling Type |

| Loading Capacity | 12 Tons |

| Loading Width | Max. 1250mm |

| Coil Inner Diameter | 450-550mm |

| Coil Outer Diameter | Max. 1500mm |

| Motor | 7.5kW+3kW |

Manual Decoiler Sample Pictures

Q: Can you customize the machine to your company’s specification?

A: Yes, we can manufacture the machine according to your specification.

Q: How is the quality?

A: All raw materials are quality controlled. Staffs take care of every detial when handling production and packaging. Our quality control department is responsible for the quality of each process.

Q: Do we have after sales service?

A: Yes, we have after sale service via email, whatsapp, wechat, skype and other communication method.

Q: Does our machine comes with warrenty?

A: Yes, it comes with 2 years warranty.